Toothed wavy spring

A technology of wave spring and tooth shape, which is applied in the direction of spring, spring/shock absorber, leaf spring, etc. It can solve the problems of inconvenient installation of wave spring, small contact area of connecting part, deviation from the axis, etc., and increase the contact area , Easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

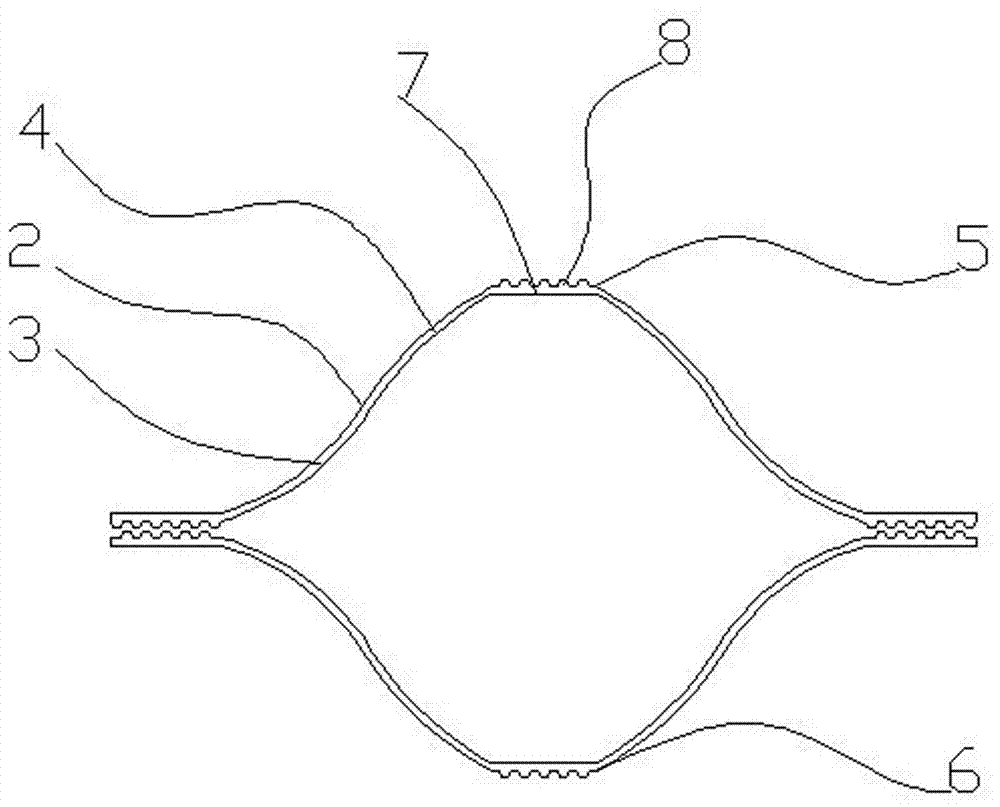

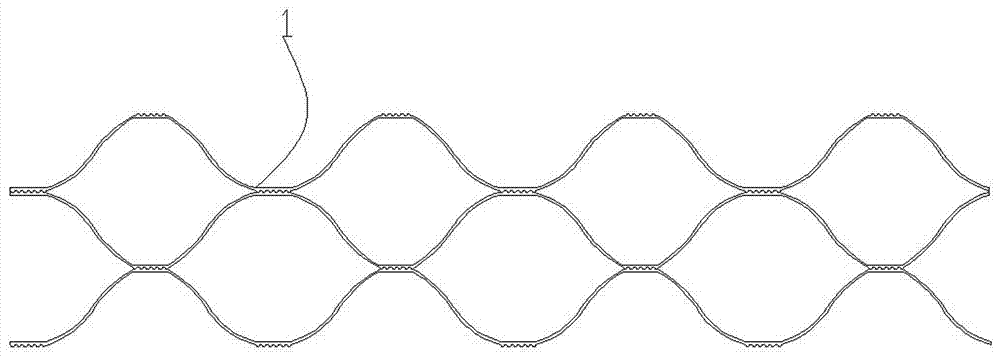

[0011] Such as figure 1 As shown, a tooth-shaped wave spring includes at least two wave spring coils 1. The cross section of the support portion 2 of the wave spring coil 1 is a sinusoidal waveform, which is composed of an inner concave arc 3 and an outer convex arc 4. The spring coil 1 includes a plurality of crests 5 and a plurality of troughs 6, the crests 5 and troughs 6 are arranged in a staggered manner, the corrugated spring coil 1 is stacked coaxially, and the crests 5 or troughs 6 are arranged as straight racks In the shape platform 7, the wave crest 5 is provided with five straight teeth upward, and the wave trough 6 is provided with six straight teeth downward.

[0012] The wave crest 5 and the straight rack platform 7 of the wave trough 6 have the same length.

[0013] The straight teeth of the crest 5 of the wave coil and the straight teeth 8 of the trough 6 can cooperate with each other.

[0014] The working principle of the present invention is described as follows: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com