Copper sheet

A technology of copper sheets and positioning sheets, applied in electrical components, transformer/inductor components, circuits, etc., can solve the problems of low product reliability, reduced production efficiency, and difficulty in ensuring size, so as to reduce labor costs and improve work efficiency. Efficiency and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

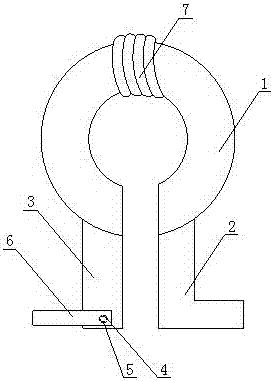

[0016] Such as figure 1 The shown copper sheet includes a copper sheet body 1, the copper sheet body 1 has an annular opening structure, and the opening of the copper sheet body 1 is provided with a first pin 2 and a second pin 3, and the second pin 3 A through hole 4 is opened on the top, and a rotating shaft 5 is installed in the through hole 4. The rotating shaft 5 is connected to the positioning piece 6. A coil 7 is wound on the copper sheet body 1. The coil 7 is on a straight line with the opening, and the first pin 2 Both the surfaces of the second pin 3 and the second pin 3 are plated with tin film, the first pin 2 is L-shaped, and the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com