Cold-rolled steel sheet and manufacturing method thereof

A technology of cold-rolled steel sheets and manufacturing methods, applied in the field of cold-rolled steel sheets, capable of solving problems such as increased residual stress, deterioration of the steel plate's resistance to hysteresis failure, and hysteresis failure, and achieving the effects of improving component strength and excellent resistance to hysteresis failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

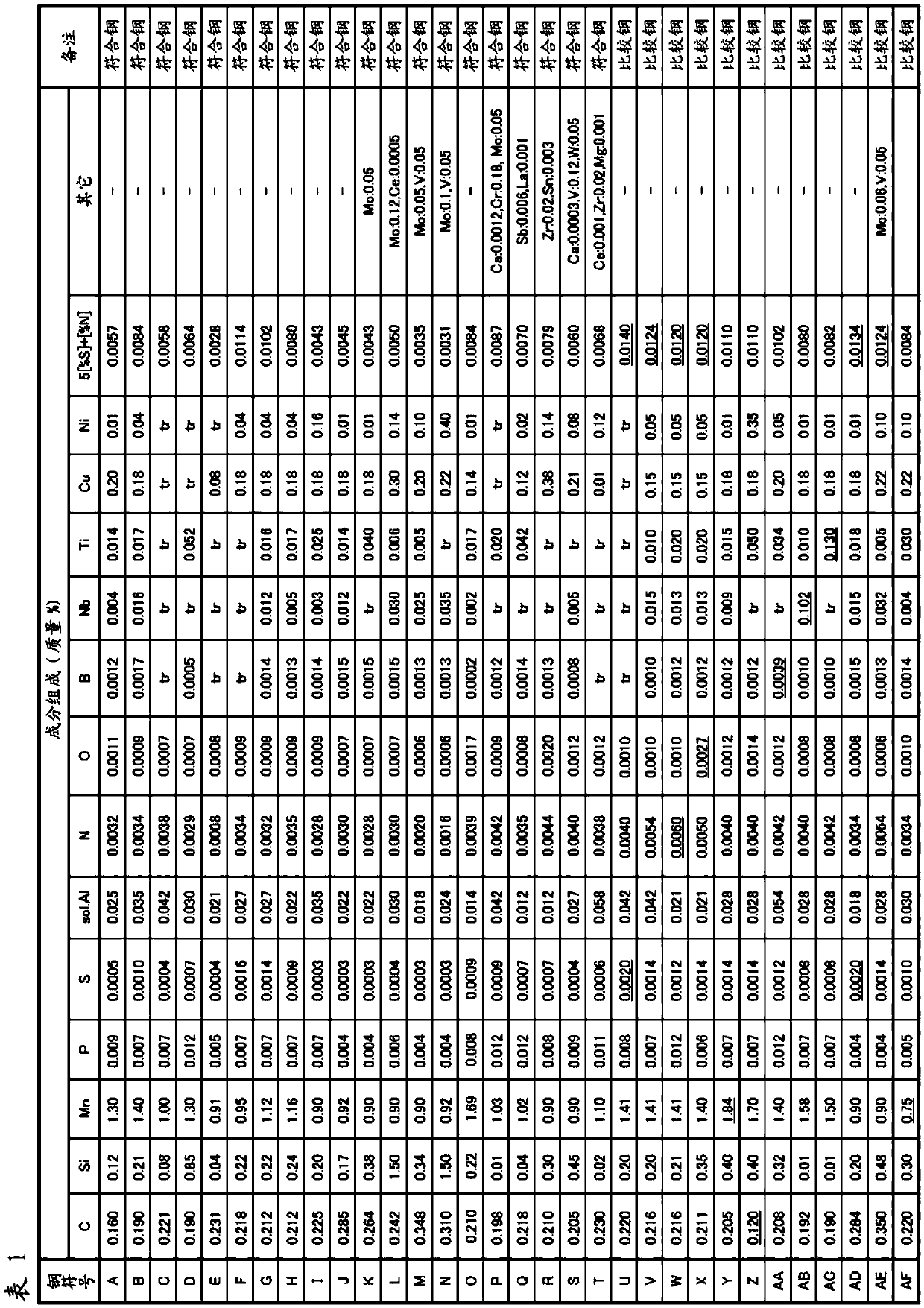

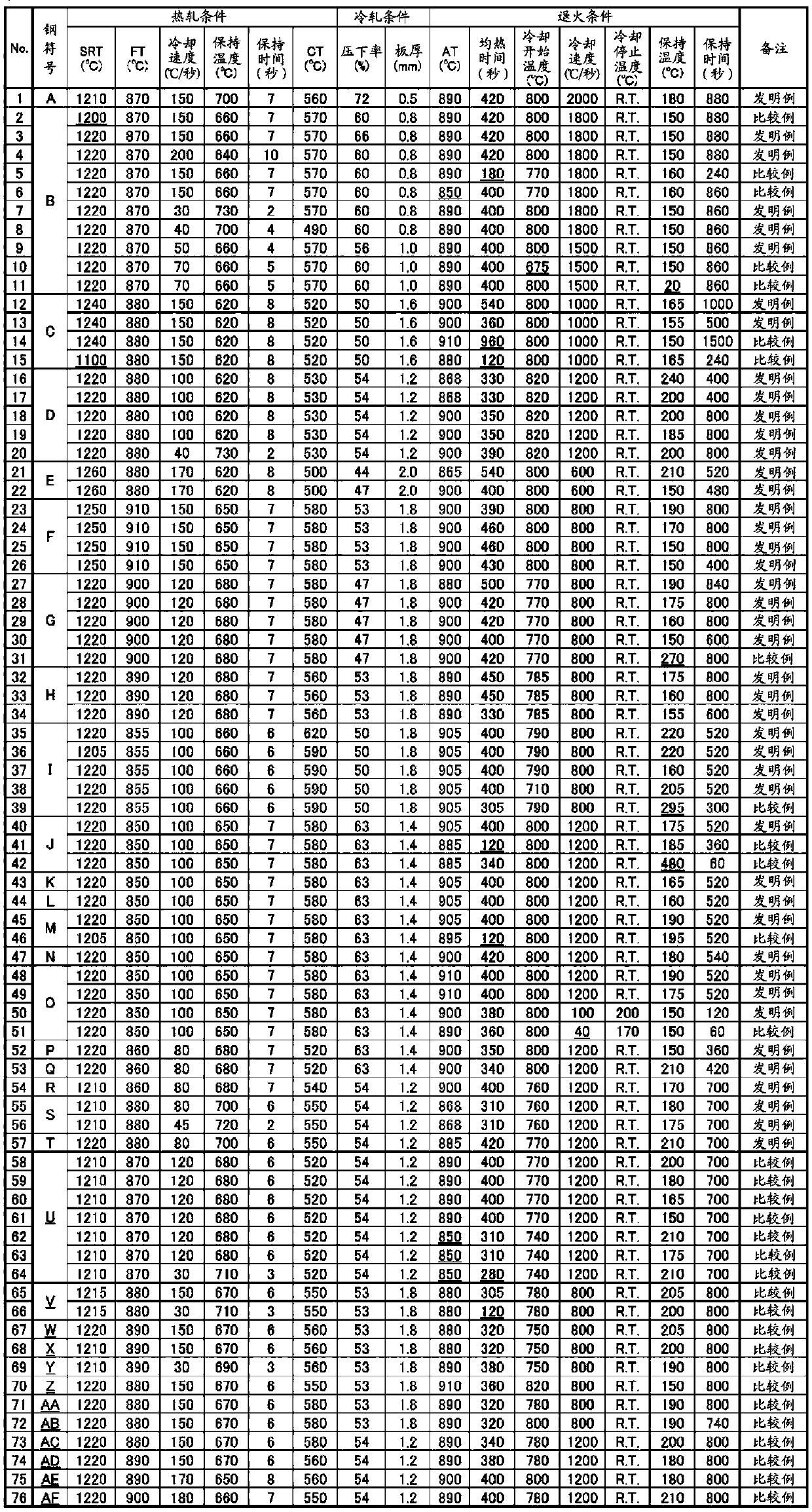

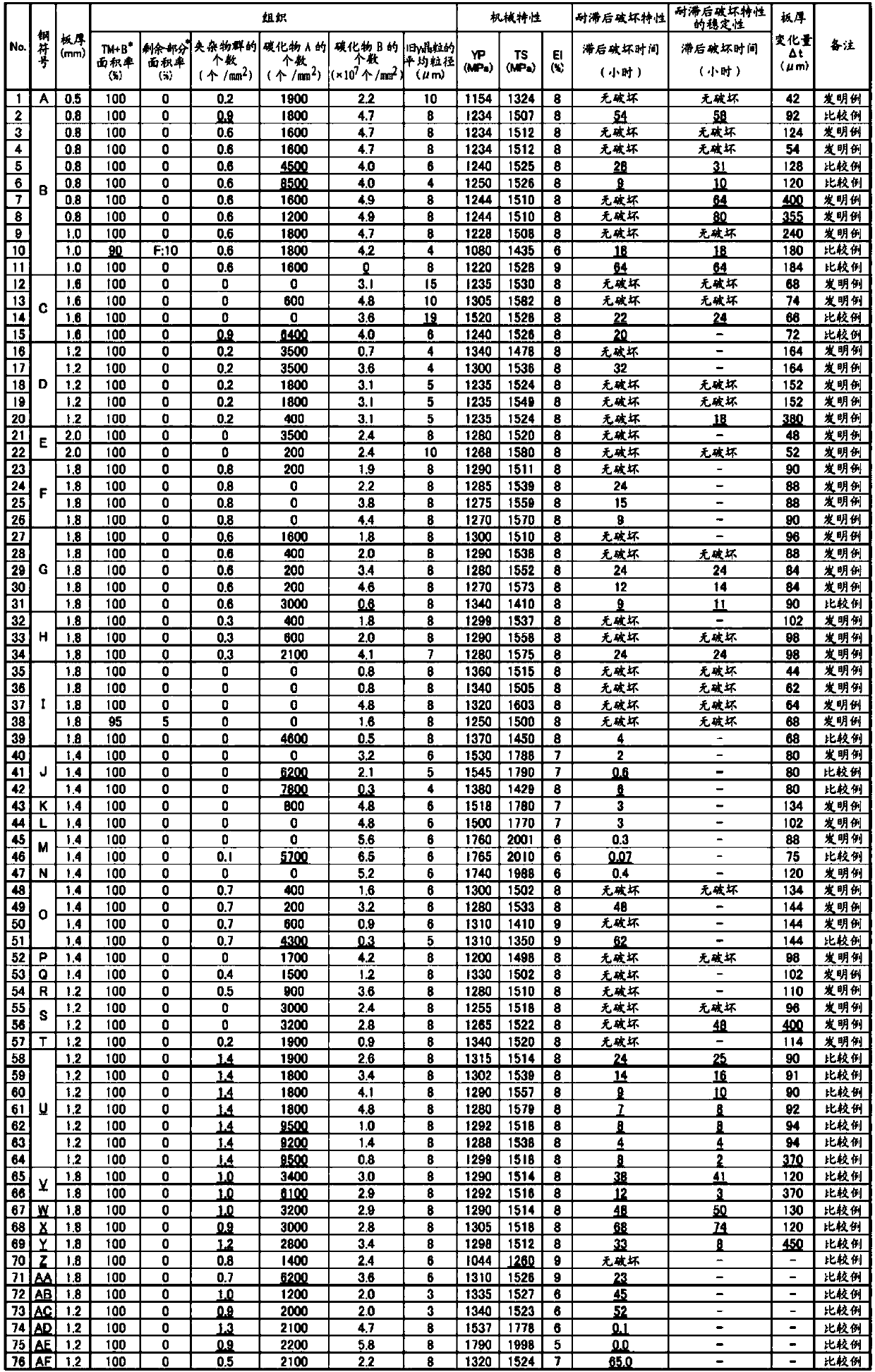

[0197] Steels with steel codes A to AF shown in Table 1 were melted and then cast into slabs with a thickness of 130 to 230 mm. According to the conditions shown in Table 2, the steel slab heating temperature (SRT) is set to 1100-1260°C, the soaking time is set to 60 minutes, and the finishing temperature (FT) is set to 850-910°C, and the cast steel slab is heated. After rolling, the average cooling rate (cooling rate) up to 700°C is set at 30-200°C / sec for cooling, and the holding temperature is set at 620-730°C for 2-10 seconds for holding , cooled again, and coiled at a coiling temperature (CT) of 490 to 620°C. The obtained hot-rolled sheet was pickled, and cold-rolled at a rolling ratio of 44 to 72% to obtain a cold-rolled steel sheet with a thickness of 0.5 to 2.0 mm.

[0198] In the continuous annealing line, according to the conditions shown in Table 2, the annealing temperature (AT) is set to 850-910°C, and the soaking time is set to 120-960 seconds, and the obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com