Semicircular zipper tooth

A zipper tooth and semi-circular technology, which is applied in the field of zipper, can solve the problems of zipper burst teeth, zipper tooth meshing is not fastened, and it is difficult to tear the zipper, so as to achieve the effect of compact structure, eliminating gaps and ensuring the meshing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

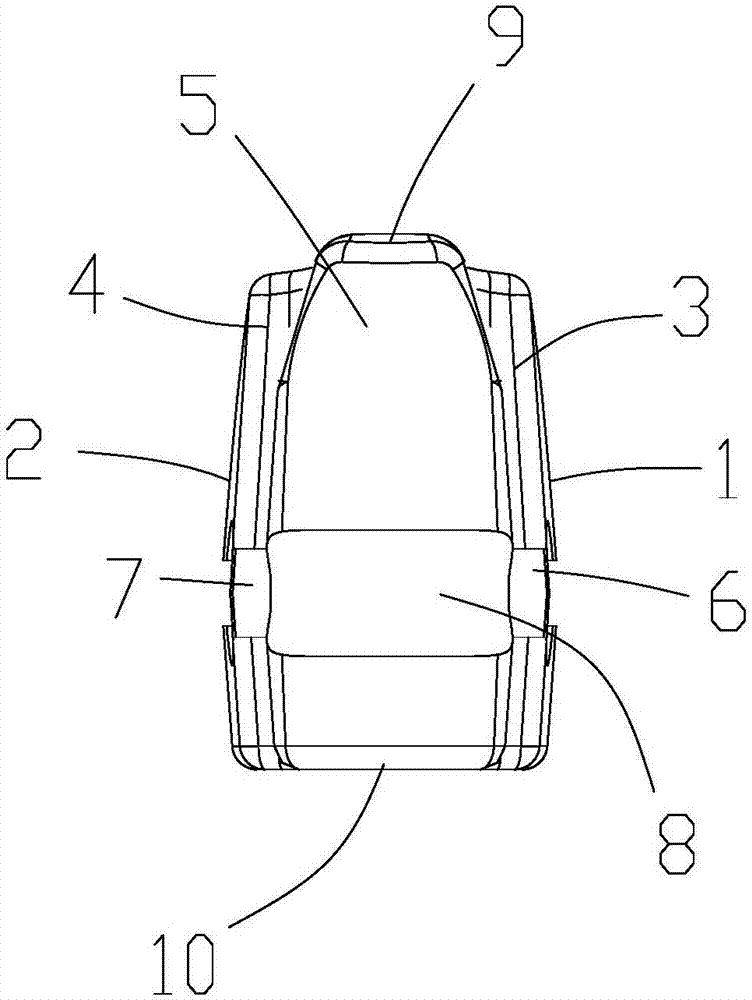

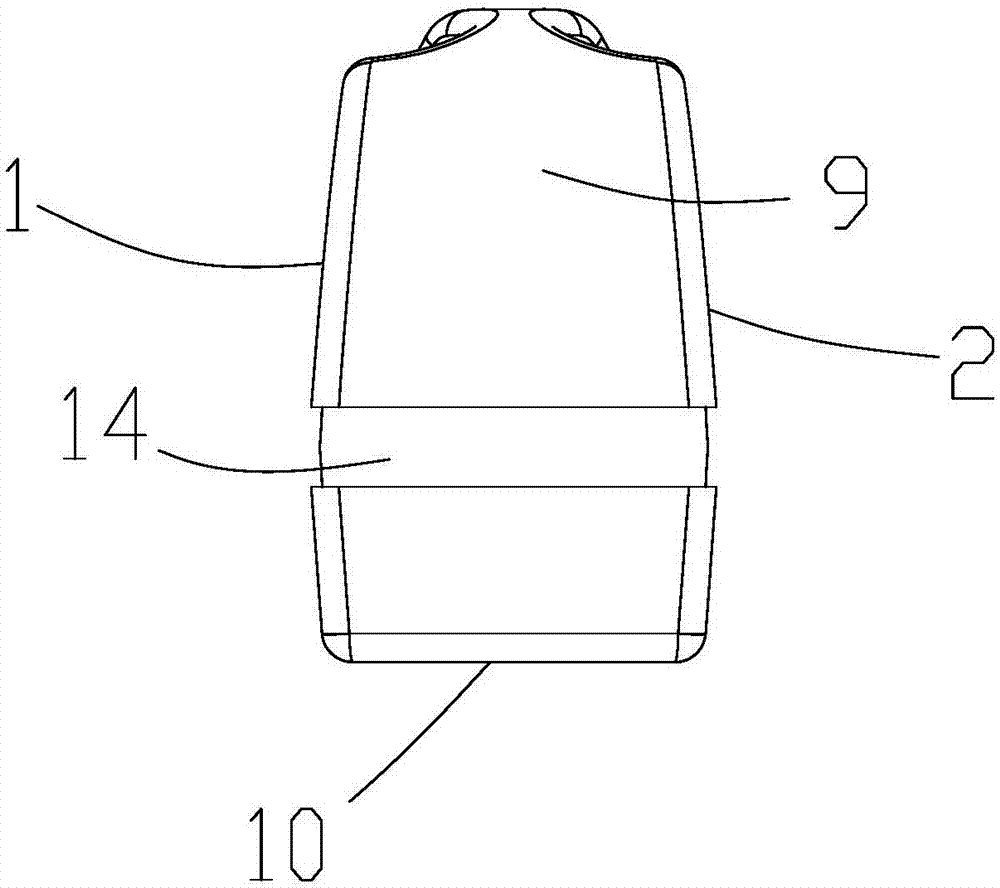

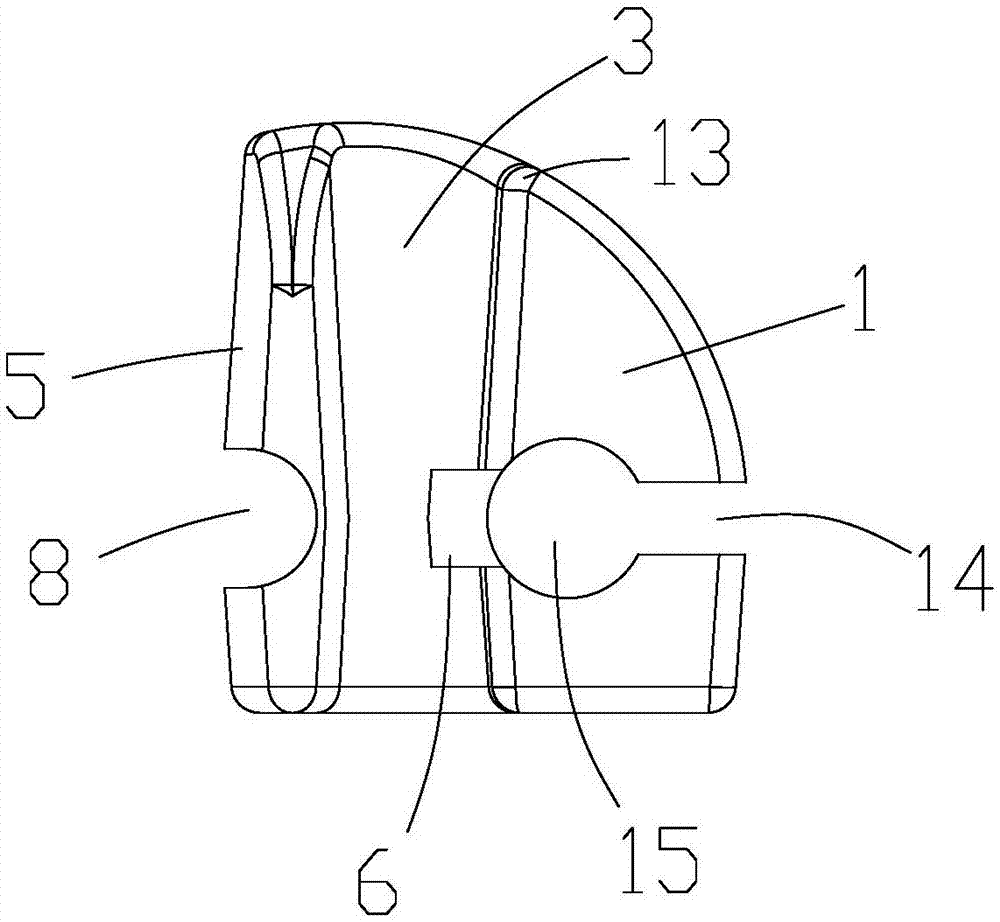

[0039] like Figures 1 to 7 A semicircular zipper element shown includes a first engaging surface 1 and a second engaging surface 2, one end of the first engaging surface 1 and one end of the second engaging surface 2 are recessed into the zipper element body to form a first The engaging recess 3, the second engaging recess 4 and the engaging part 5;

[0040] The first engaging recess 3 is provided with a protruding first positioning portion 6 on the side away from the engaging portion 5 , and the second engaging recess 4 is provided with a protruding first positioning portion 6 on the side away from the engaging portion 5 . The second positioning part 7 raised, the end surface of the engaging part 5 is provided with a positioning groove 8 corresponding to the position of the first positioning part 6 and the second positioning part 7, and the connecting end surface of one end of the engaging part 5 is arc-shaped The upper side part 9 of the fastener element, the two sides of ...

Embodiment 2

[0054] Such as Figures 1 to 7 A semicircular zipper element shown includes a first engaging surface 1 and a second engaging surface 2, one end of the first engaging surface 1 and one end of the second engaging surface 2 are recessed into the zipper element body to form a first The engaging recess 3, the second engaging recess 4 and the engaging part 5;

[0055] The first engaging recess 3 is provided with a protruding first positioning portion 6 on the side away from the engaging portion 5 , and the second engaging recess 4 is provided with a protruding first positioning portion 6 on the side away from the engaging portion 5 . The second positioning part 7 raised, the end surface of the engaging part 5 is provided with a positioning groove 8 corresponding to the position of the first positioning part 6 and the second positioning part 7, and the connecting end surface of one end of the engaging part 5 is arc-shaped The upper side part 9 of the fastener element, the two sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com