Three-dimensional intelligent liquid preparing system

An intelligent and liquid technology, applied in the preparation of test samples, etc., can solve the problems of user maintenance costs, instrument footprint, simplified and single functions, etc., to achieve less sample volatilization and pollution, reduced floor space, and preparation process accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0159] 2.1. Overall implementation of the system

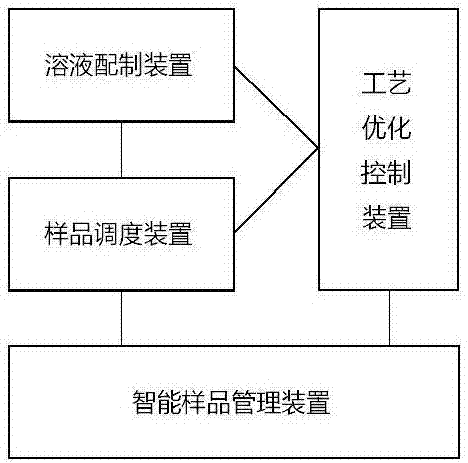

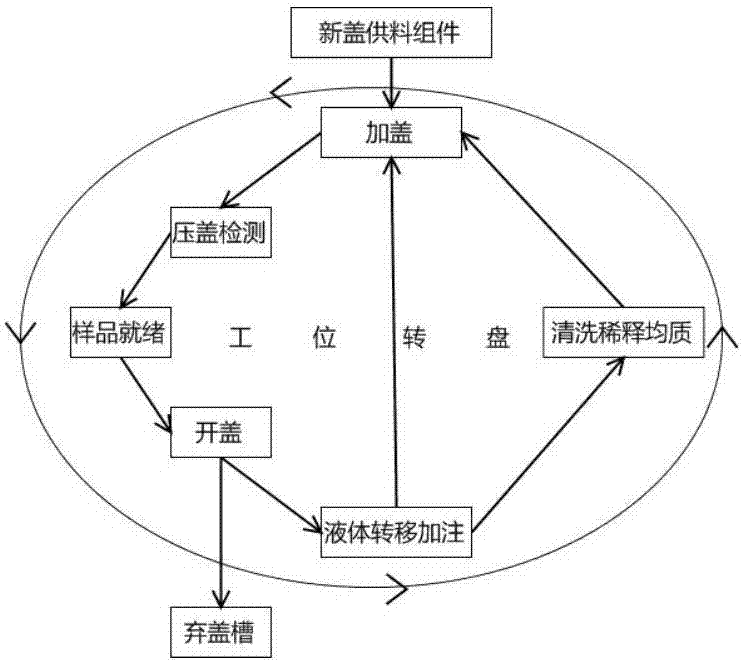

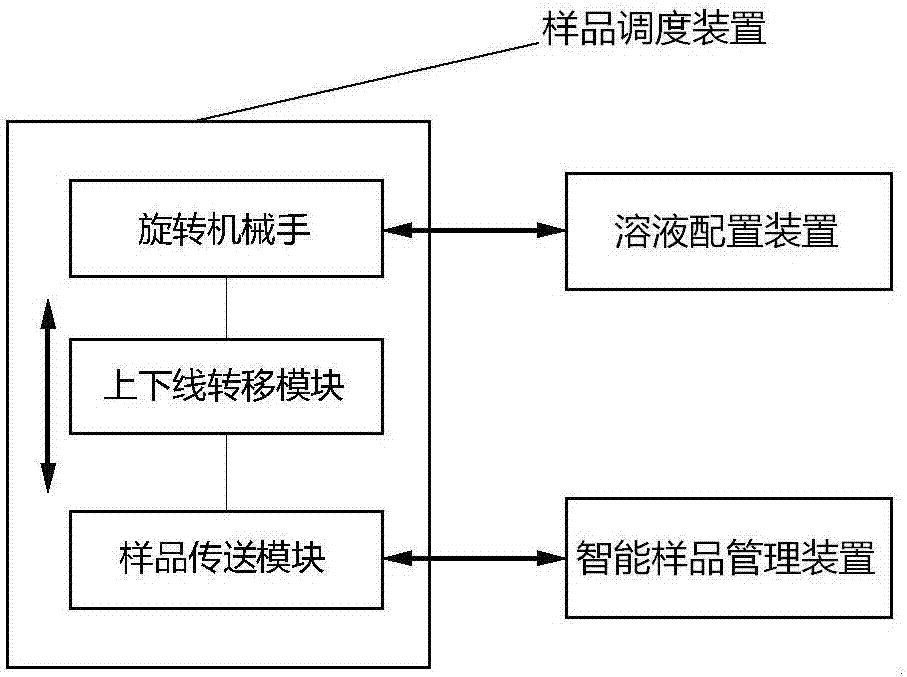

[0160] The system adopts three-dimensional design, including intelligent sample management device, sample scheduling device, solution preparation device and process optimization control device; the intelligent sample management device is in the lower layer, including sample input module, sample inventory optimization module, sample identification module, sample quality traceability module and sample tank management module; the solution preparation device is on the upper floor, including station turntable, uncapping / capping module, liquid transfer, filling, cleaning, dilution and homogenization module, and its uncapping / capping module can be Reduce the volatilization, deterioration and pollution of samples during the liquid preparation process; the sample scheduling device is used to realize the transfer of samples between the lower intelligent sample management device and the upper solution preparation device, including a sampl...

specific Embodiment 2

[0207] For the metalaxyl of 50ppm and 0.01ppm of metalaxyl mixed standard solution 50mL that needs to be prepared, 30mL of metalaxyl of existing standard solution 1000ppm, 10mL of metalaxyl of 500ppm, 10mL of cloclofenapyr of 1000ppm, adopt the method based on the present invention The mixed integer programming linear programming method for the optimization method of the mixed standard solution preparation route, the specific operation steps are as follows:

[0208] (1) According to the requirements, it can be known that the mixed standard solution to be prepared, its component metalaxyl t 1 concentration Composition 2 concentration The volume V of the mixed standard solution t =50mL

[0209] (2) According to the existing conditions, it can be known that there is a single standard standard solution s 11 (The solute is metalaxyl, concentration effective volume ), s 12 (The solute is metalaxyl, concentration effective volume ),s 21 (The solute is metalaxyl, conc...

specific Embodiment 3

[0222] For the metalaxyl of 50ppm and 0.01ppm of metalaxyl mixed standard solution 50mL that needs to be prepared, 30mL of metalaxyl of existing standard solution 1000ppm, 10mL of metalaxyl of 500ppm, 10mL of cloclofenapyr of 1000ppm, adopt the method based on the present invention The mixed integer programming linear programming method for the optimization method of the mixed standard solution preparation route, the specific operation steps are as follows:

[0223] (1) According to the requirements, it can be known that the mixed standard solution to be prepared, its component metalaxyl t 1 concentration Composition 2 concentration The volume V of the mixed standard solution t =50mL

[0224] (2) According to the existing conditions, it can be known that there is a single standard standard solution s 11 (The solute is metalaxyl, concentration effective volume ), s 12 (The solute is metalaxyl, concentration effective volume ),s 21 (The solute is metalaxyl, concen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap