Tension mechanism of paying-off device

A technology of tensioning mechanism and pay-off device, which is applied in the field of tensioning mechanism, can solve problems such as subsidence, line jamming, and inability to meet high-efficiency production requirements, and achieve the effect of ensuring the stability of cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The purpose of this specific embodiment is to provide a tensioning mechanism of a pay-off device, which can ensure the stability of the coil and prevent the coil from being stuck or collapsed during the pay-off process.

[0022] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

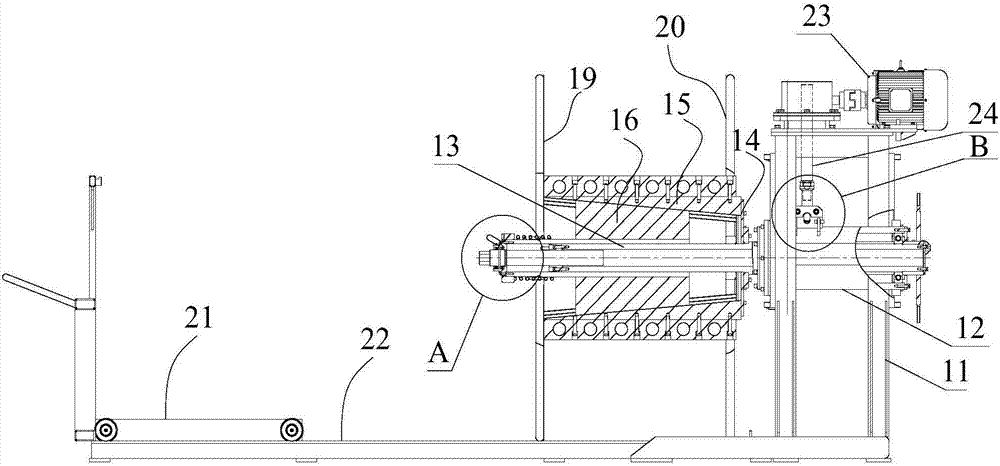

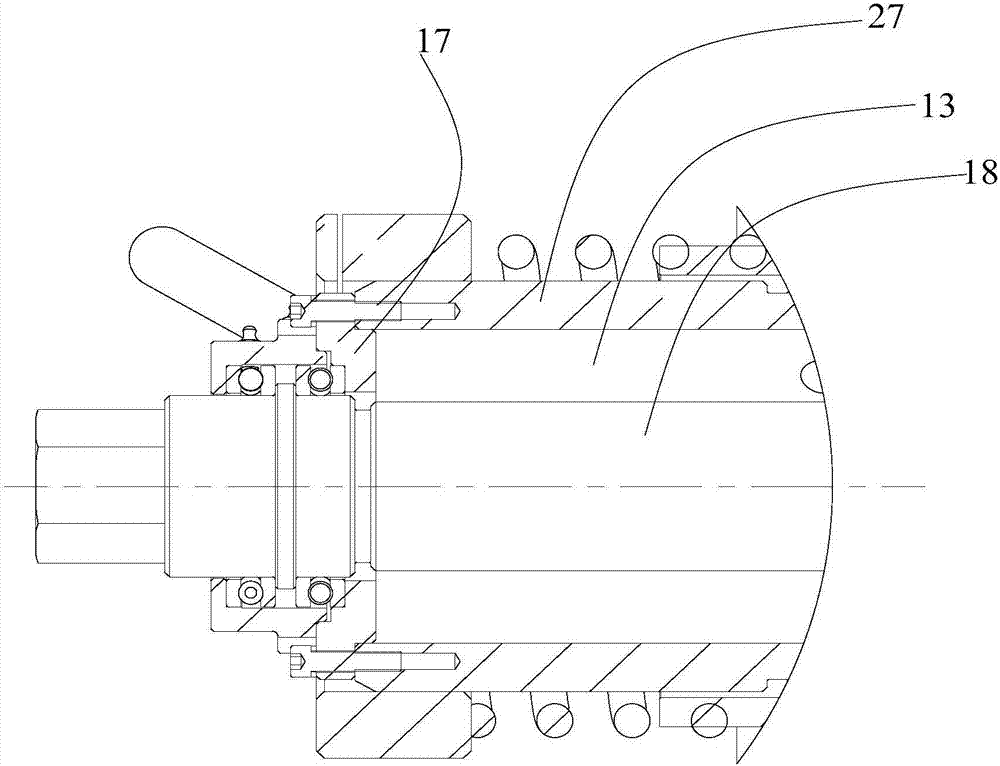

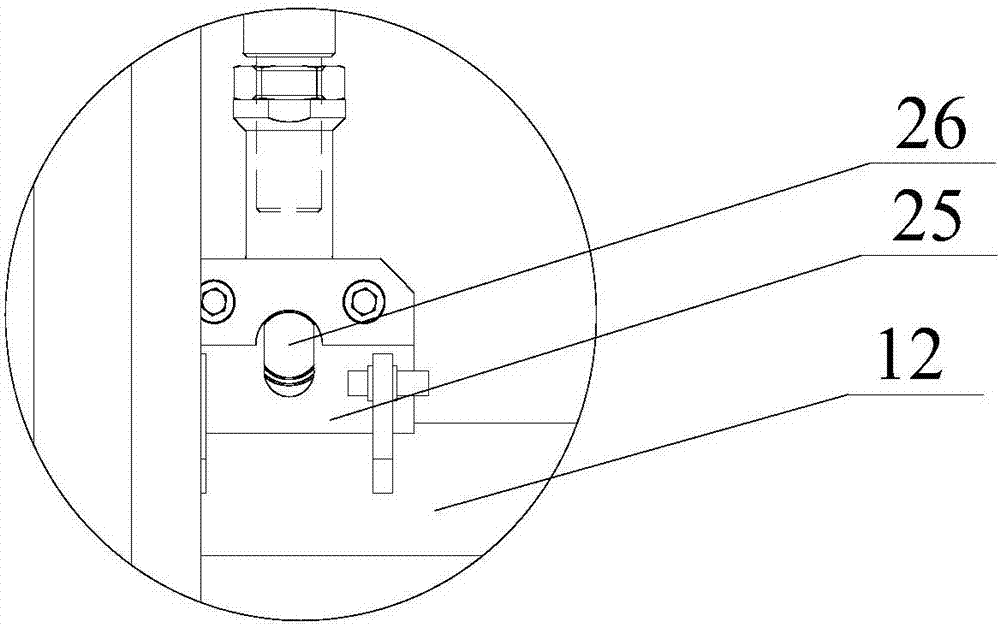

[0023] see Figure 1-Figure 3 , the tensioning mechanism of the pay-off device provided in this embodiment, the guide disc 14, a plurality of radially moving blocks 15, the axially moveable block 16 and the axial drive mechanism, wherein the guide disc 14 is fixedly arranged on the main shaft of the pay-off device 13, a plurality of radially moving blocks 15 are distributed alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com