Wood plastic wallboard easy to assemble

A wood-plastic wall panel, easy to assemble technology, applied in the direction of floor, covering/lining, building, etc., can solve the problems of easy falling off due to vibration, inconvenient assembly, poor structural strength, etc., to improve aesthetics and improve assembly efficiency , Improve the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

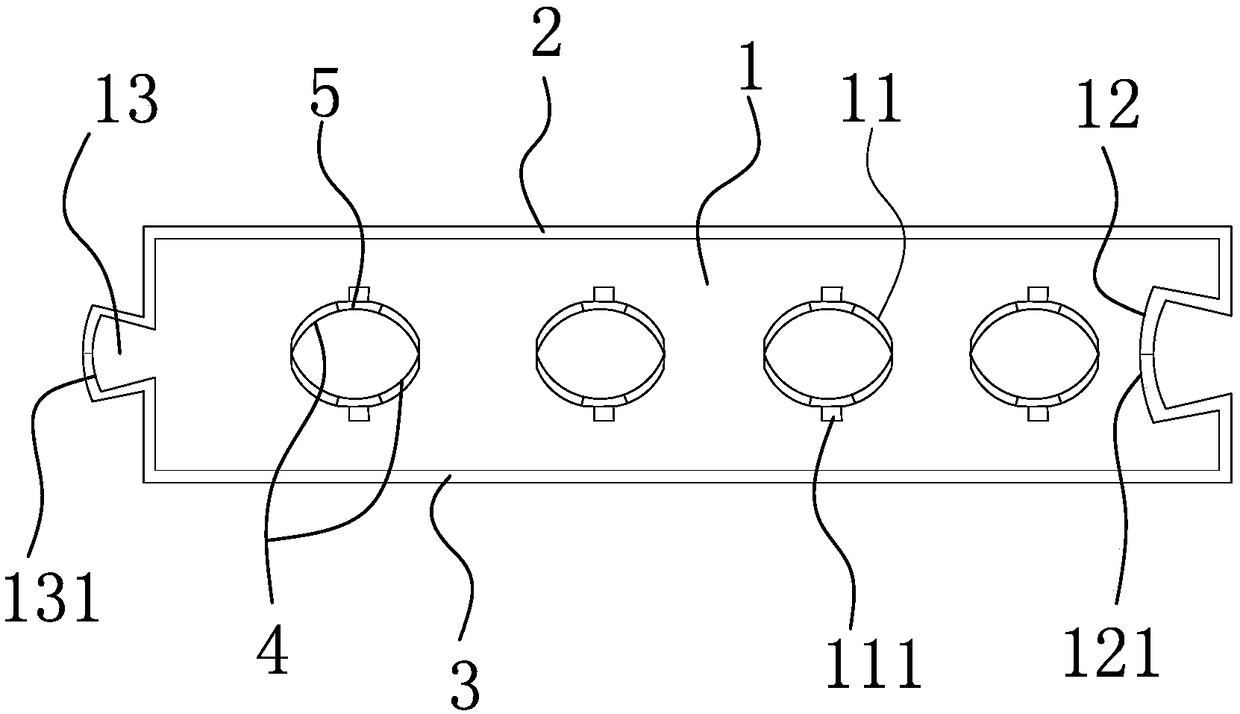

[0030] Such as figure 1 Show,

[0031] The easy-to-assemble wood-plastic wall panel includes a board body 1, and the parallelism between the front and back of the board body 1 is 0.1 mm.

[0032] Embossing patterns are arranged on the front of the board body 1, and a surface decorative veneer 2 is arranged on the front of the board body 1, and the surface decorative veneer 2 and the board body 1 are fixed by bonding glue. That is, the embossed pattern increases the storage capacity, and can further improve the stability of the surface decorative veneer 2 being fixed.

[0033] In the plate body 1, there are several oval holes 11 arranged along the length direction of the plate body 1, and the oval holes 11 are evenly spaced. 11....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com