Chain plate pin shaft and machining process thereof

A processing technology and chain plate technology, applied in the direction of pins, chain rings, transmission chains, etc., can solve the problem of poor cooperation between the end 2 and the groove 40, the reduction of the force bearing area of the mating surface, and the difficulty in achieving a smooth transition, etc. problem, to achieve the effect of improving service life and use effect, reducing stress concentration and reducing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

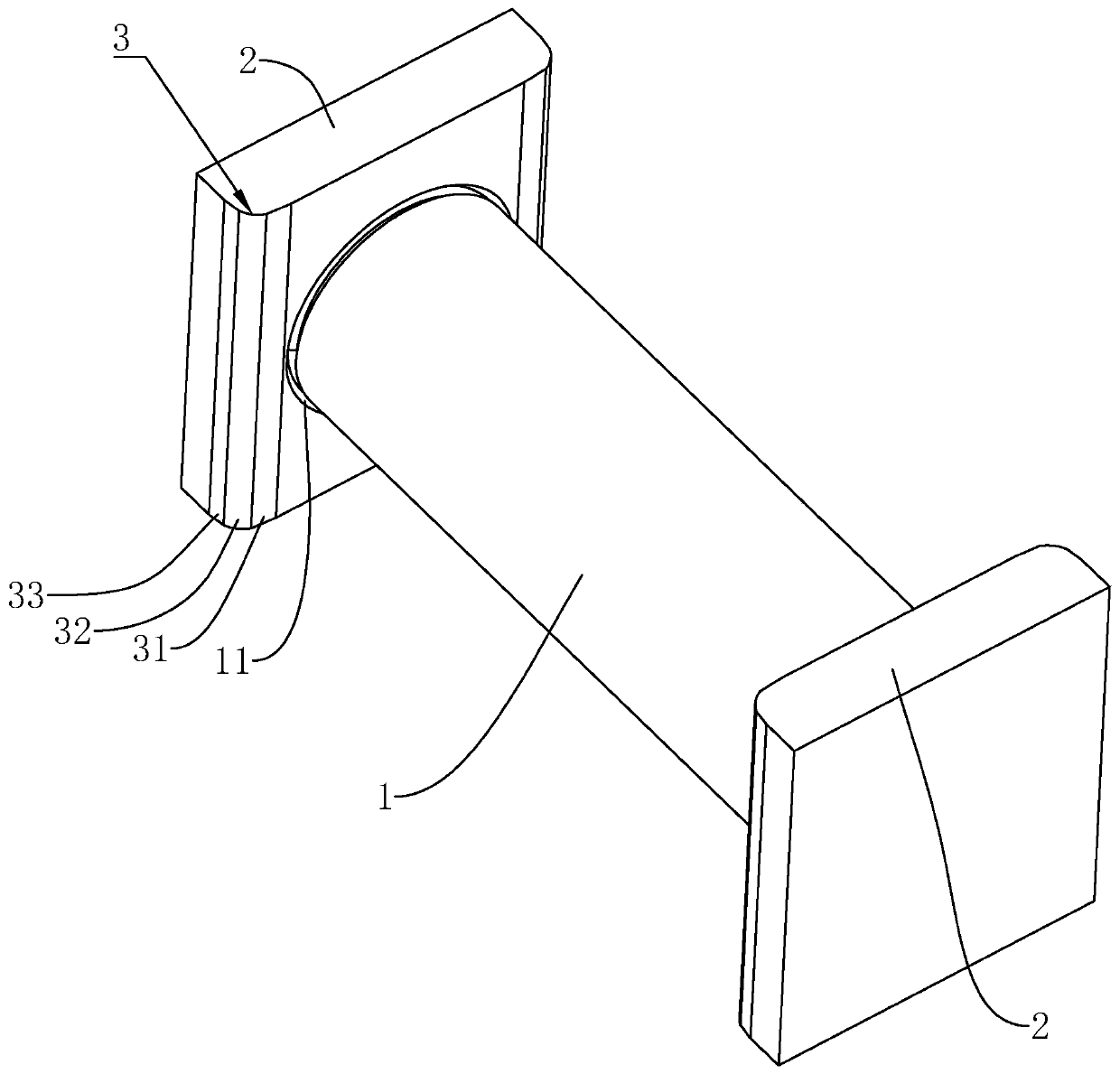

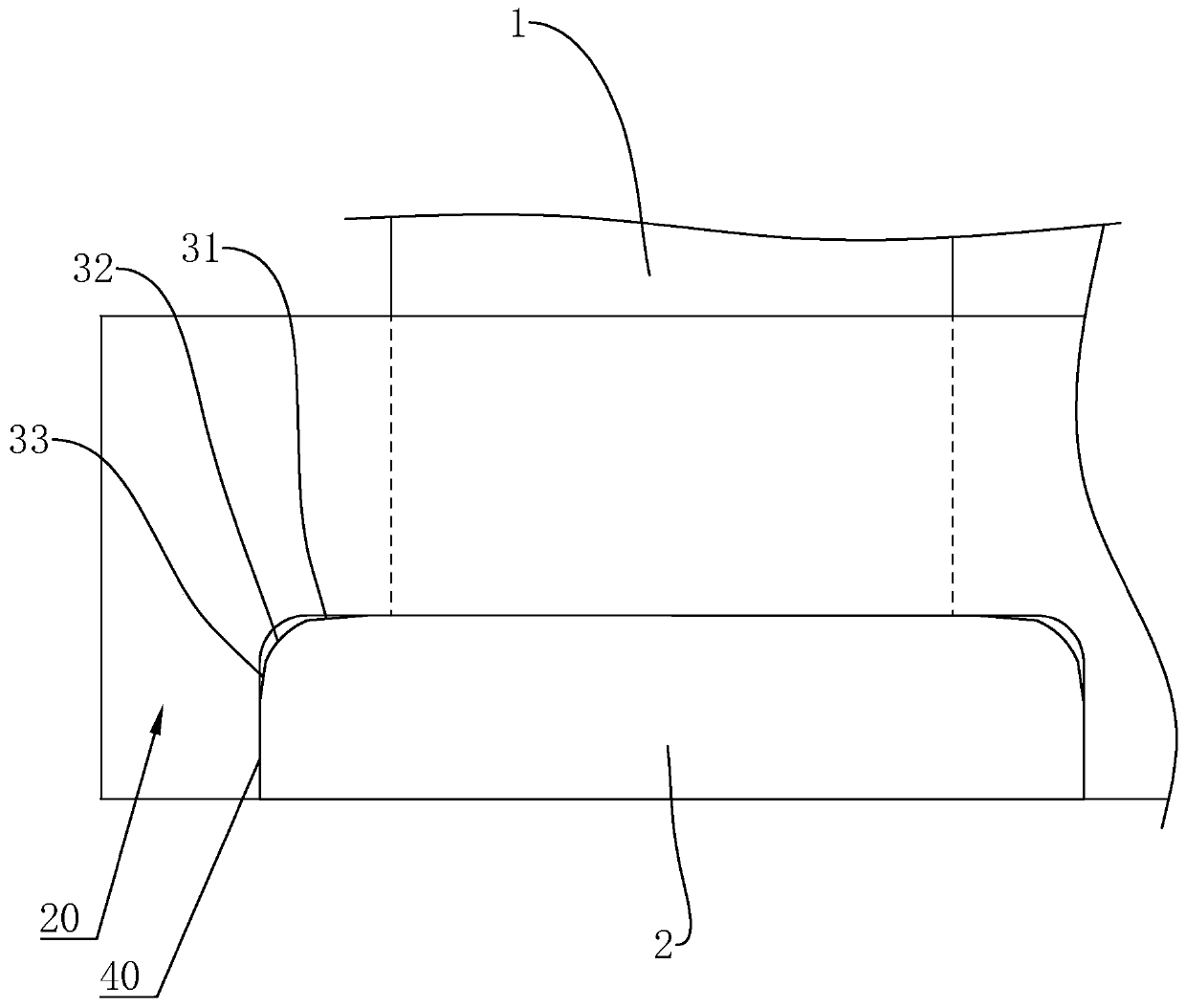

[0057] Embodiment 1: as figure 1 As shown, it is a chain plate pin disclosed by the present invention, which includes a shaft body 1 and two square ends 2 symmetrically fixed to one side of the shaft body 1 .

[0058] The surface roughness of the peripheral surface of the shaft body 1 is less than 0.25 μm, and an undercut 11 is provided at the junction between the peripheral surface of the shaft body 1 and the inner end surface of the end head 2; by defining the surface of the peripheral surface of the shaft body 1 The roughness improves the surface quality of the peripheral surface of the shaft body 1, thereby improving the cooperation between the peripheral surface of the end head 2 and the inner chain plate 30, and further improving the service life and use effect of the chain.

[0059] The diameter of the shaft body 1 is D. When 10mm<D≤18mm, the tolerance range of D is -2.5μm to +2.5μm; when 18mm<D≤30mm, the tolerance range of D is -3μm to +3μm; when When 30mm<D≤50mm, th...

Embodiment 2

[0064] Embodiment 2: A kind of processing technology of chain plate pin shaft, comprises the following steps:

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com