Gear sleeving device of electrical parking brake kinetic energy motor gear assembly device

A technology of motor gears and assembling devices, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

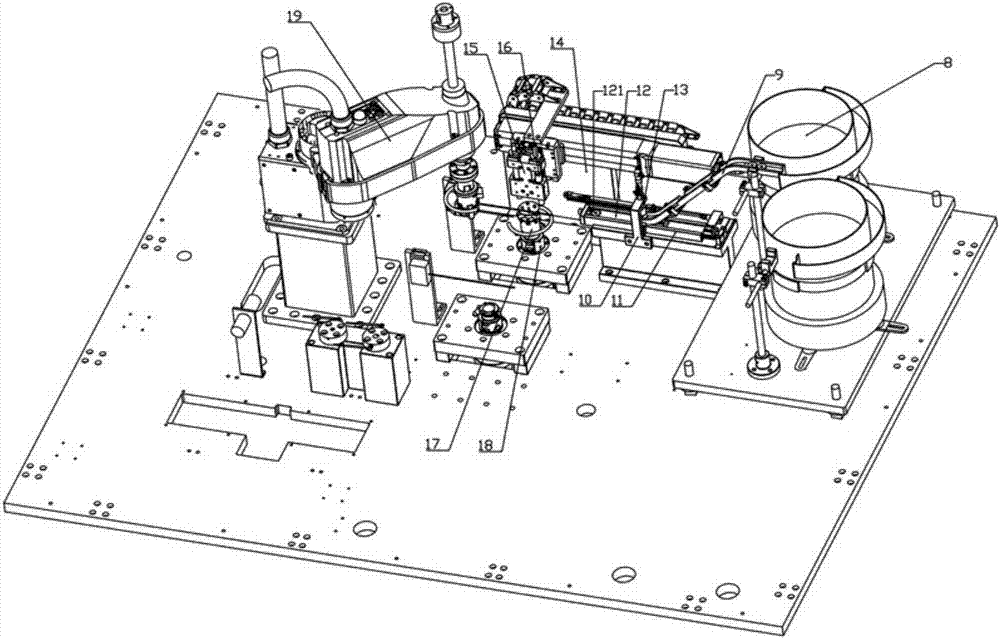

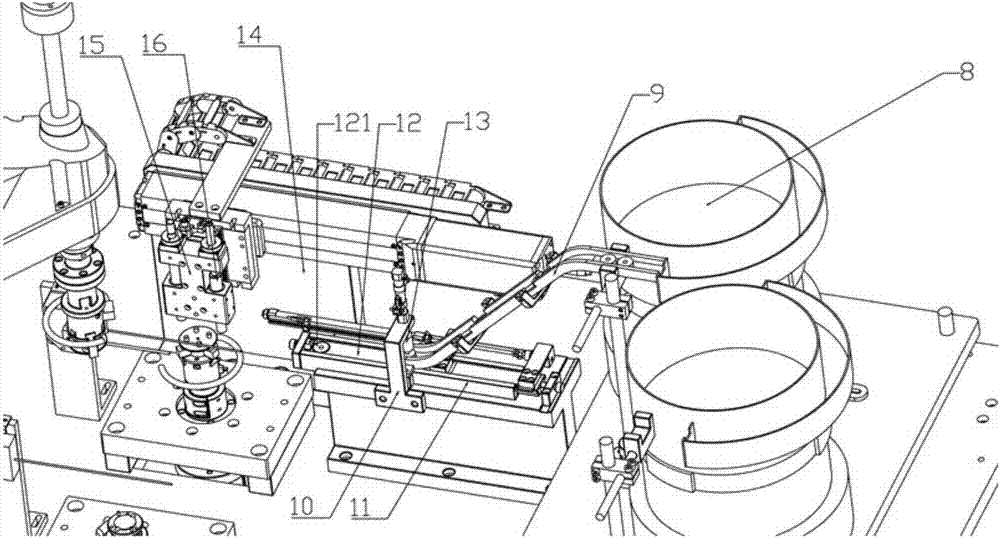

[0024] See Figure 1-2 , An electronic parking kinetic energy motor gear assembly device gear sleeve taking device, having:

[0025] Vibrating bucket, used to accommodate gears;

[0026] The slide, connected with the vibrating bucket, can output gears;

[0027] Pushing track, set at the end of the slide;

[0028] The push block can slide on the pushing track and push out the gear;

[0029] The toothing bracket is set on the bottom plate;

[0030] The positioning block is slidably installed on the gear shaper bracket; the positioning block is driven to slide by the electric cylinder.

[0031] The gear pick-up shaft is slidably installed in the positioning block, and the gear pick-up shaft is matched with the shaft hole of the gear;

[0032] The electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com