Die for manufacturing centrifugal impeller

A centrifugal impeller and mold technology, applied in household appliances, other household appliances, applications, etc., can solve the problems of time-consuming and laborious, low connection structure strength, and failure to meet performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

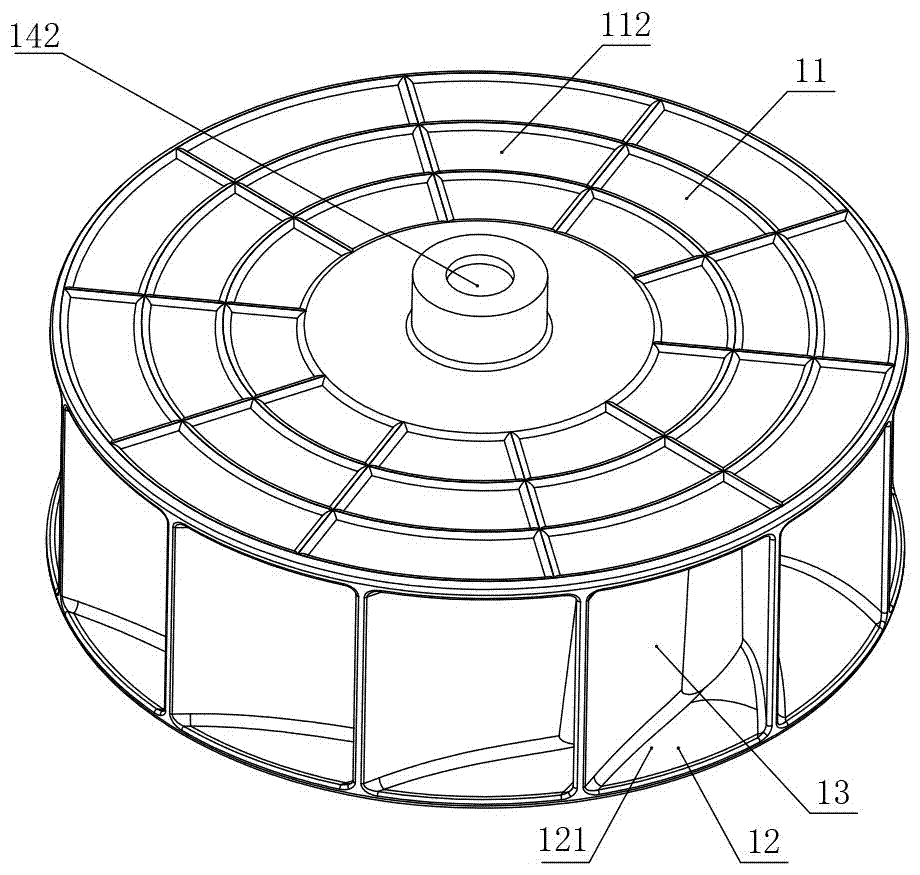

[0020] Figure 1 to Figure 4 The centrifugal impeller shown includes a front disc 12, a blade 13, and a rear disc 11. The front disc 12 and the rear disc 11 are two disc-shaped bodies located on the upper and lower sides of the blade 13, which constitute the installation base of the blade 13, and the blade 13 is located in the front Between the disc 12 and the rear disc 11, the front disc 12, the blades 13, and the rear disc 11 are integrally formed.

[0021] It should be noted that the so-called up, down, height, horizontal, vertical and other words related to orientation in the present invention are described based on the direction shown in the drawings as a standard, and do not mean the actual assembly or running direction. , and it should be understood as a general direction, and should not be limited to the absolute value in the geometric sense, because a little error in assembly absolutely exists and should be allowed.

[0022] It can be seen that the front disk 12 is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com