Bridge device

A technology of bridges and chambers, applied in the field of bridge devices, can solve problems such as energy consumption, increased construction costs, unevenness, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

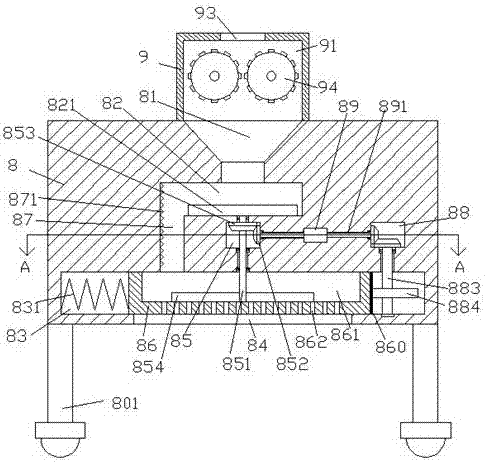

[0020] Such as Figure 1-Figure 4 As shown, a bridge device of the present invention includes a base 8 and a stone crushing part 9 installed on the top of the base 8, and a connecting cavity 81 extending downward is provided on the top surface of the base 8. The bottom of the connecting chamber 81 is connected with a first chamber 82 extending to the left and right sides, and a second chamber 83 is provided in the base 8 below the first chamber 82. The inner bottom wall of the chamber 83 is provided with a soil discharge port 84 passing through the bottom surface of the base 8, and a third chamber is provided in the base 8 between the first chamber 82 and the second chamber 83. Chamber 85, the base 8 on the left side of the third chamber 85 is provided with a vertical cavity 87 extending up and down, the top of the vertical cavity 87 is extended and the tail is connected to the left extension of the first chamber 82. The bottom of the vertical chamber 87 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com