Secondary springboard automatic turnover mechanism provided with latching device

A flipping mechanism and automatic flipping technology, applied in construction and other directions, can solve the problems of accidental flipping of large springboard lock failure, low degree of control of operation process, damage to personnel and equipment, etc., to achieve high safety, low labor intensity, and improved reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

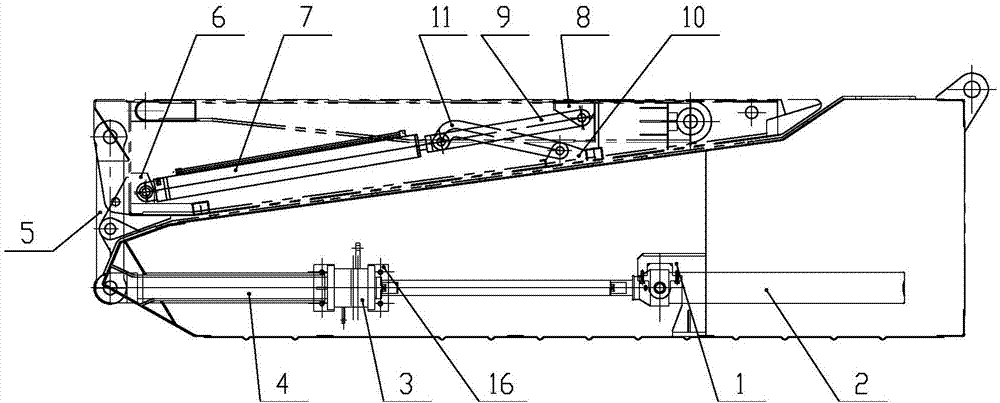

[0022] This embodiment provides a secondary springboard turning mechanism with a locking device for a crawler self-propelled pontoon, which can reliably realize the automatic turning over of large and small springboards and the turning and locking of large springboards.

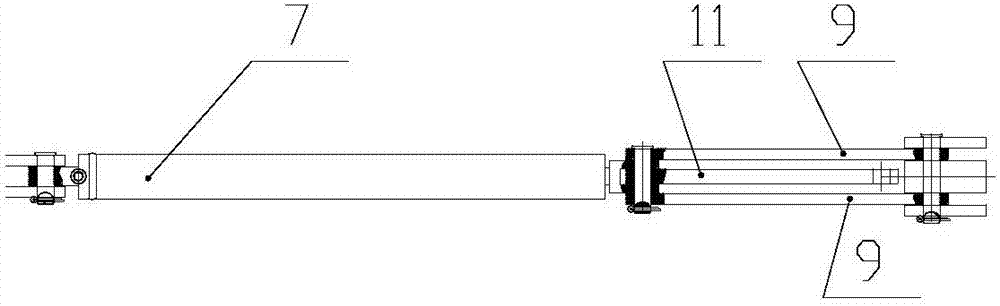

[0023] The secondary springboard turning mechanism includes a large springboard turning mechanism, a large springboard turning mechanism locking device and a small springboard turning mechanism.

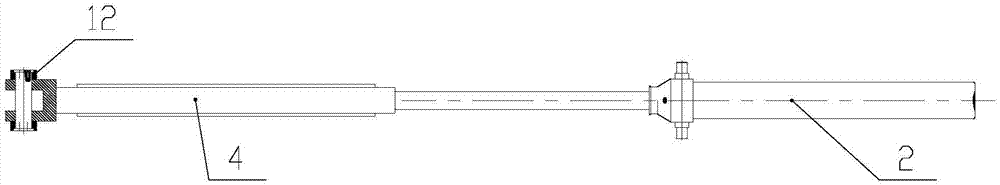

[0024] like figure 1 and figure 2 As shown, the turning mechanism of the large springboard includes: the first oil cylinder seat 1, the first turning oil cylinder 2, the cylinder push-pull rod 4 and the connecting rod 5; wherein the first oil cylinder seat 1 is welded in the box body of the crawler self-propelled pontoon bridge, and the pin shaft and the The connecting holes at the tail of the first turnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com