Building floor tile

A technology for floor tiles and buildings, applied in buildings, building structures, floors, etc., can solve problems such as difficult to remove, affect aesthetics, and non-carrying colors, and achieve the effect of easy cleaning and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

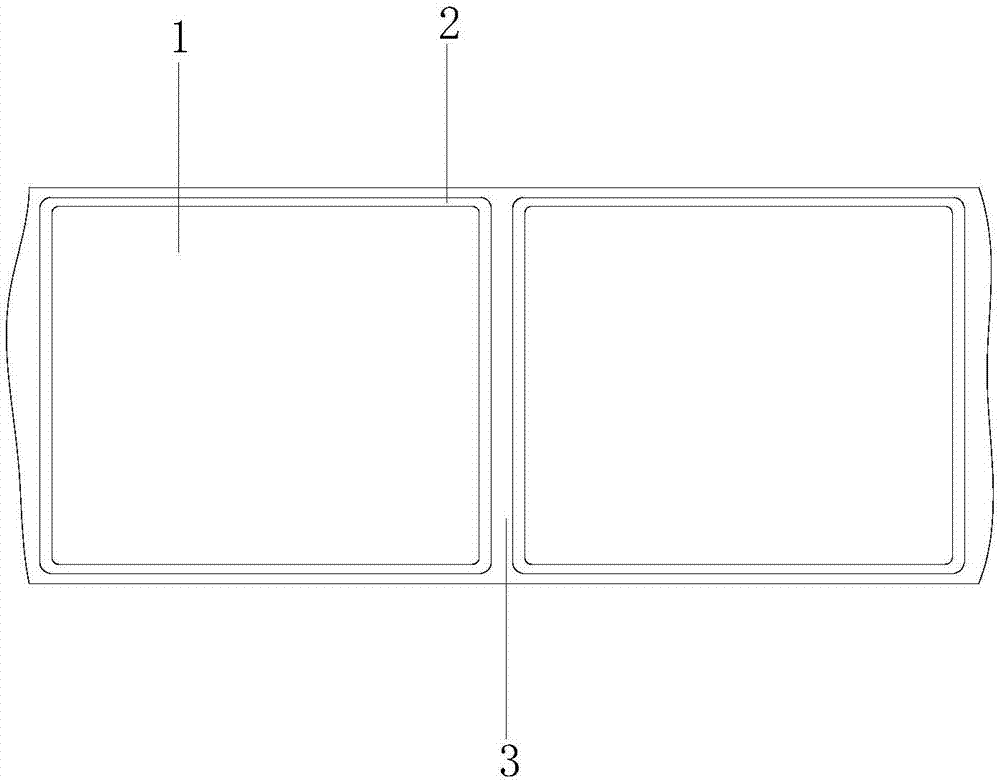

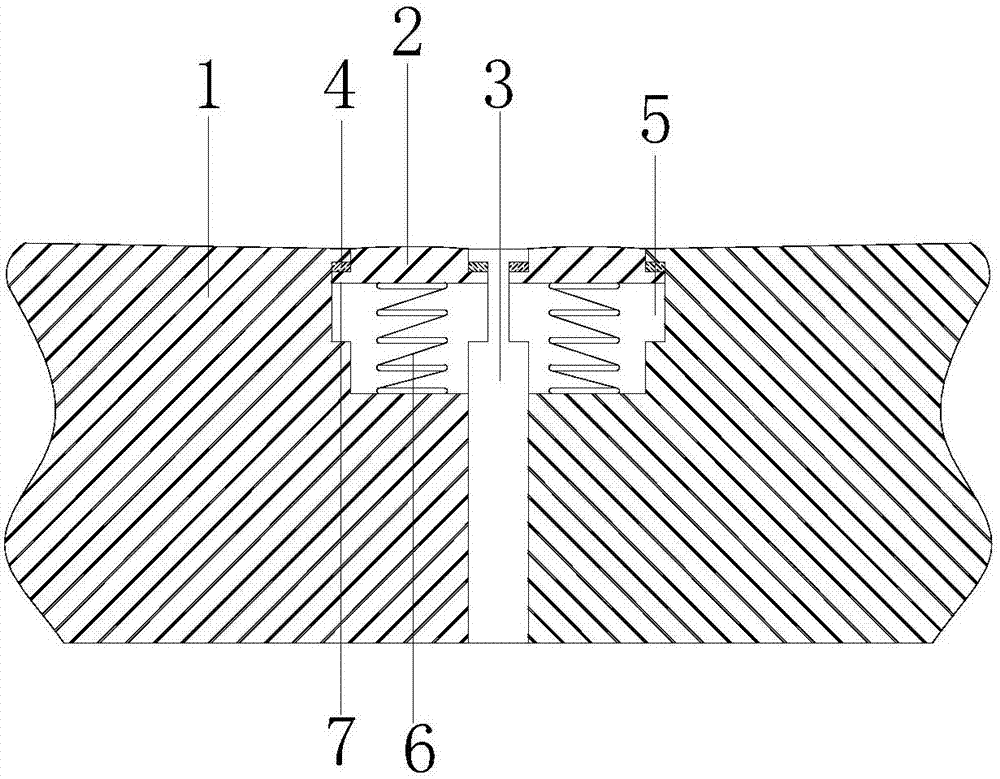

[0015] Such as figure 1 and figure 2 As shown, the floor tiles of this building include floor tiles 1 that are spliced with each other. A metal decorative edge 3 is arranged between the floor tiles 1 and the floor tiles 1. The metal decorative edge 3 is as high as the floor tiles 1 and is laid on the ground along each floor tile 1. A circle of movable ring 2 is arranged at the junction of the floor tile 1 and the metal decorative edge 3, and the movable ring is movably installed in the groove provided on the outer ring of each floor tile;

[0016] The groove is provided with a first chute opposite to the inner wall of the metal decorative edge, and the inner wall of the metal decorative edge facing the first chute is provided with a second chute 5, and the two sides of the movable ring 2 are facing the first and second chute respectively. A rib 7 is provided, and the rib 7 is slidably installed in the chute. The upper end surface of the rib 7 is provided with a water-absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com