A structure for suppressing forward transmission of gas in an air-breathing pulse detonation engine

A pulse detonation and engine technology, applied in mechanical equipment, intermittent injection devices, etc., can solve the problems of difficult intake, large intake flow resistance, thrust loss, etc., to achieve large flow resistance, reduce thrust loss, and smooth intake Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Describe the present invention below in conjunction with specific embodiment, accompanying drawing:

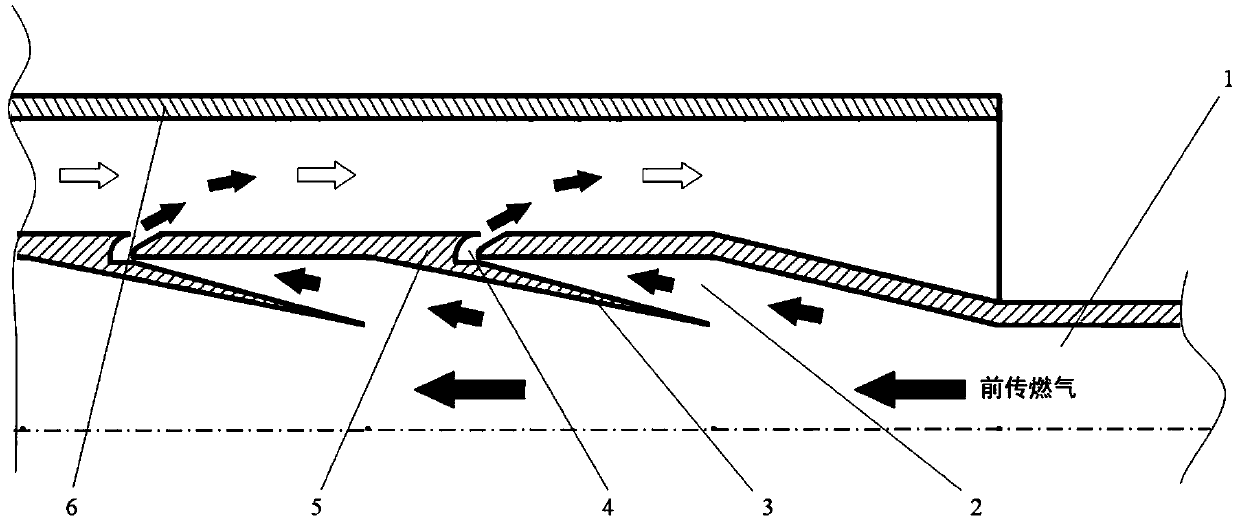

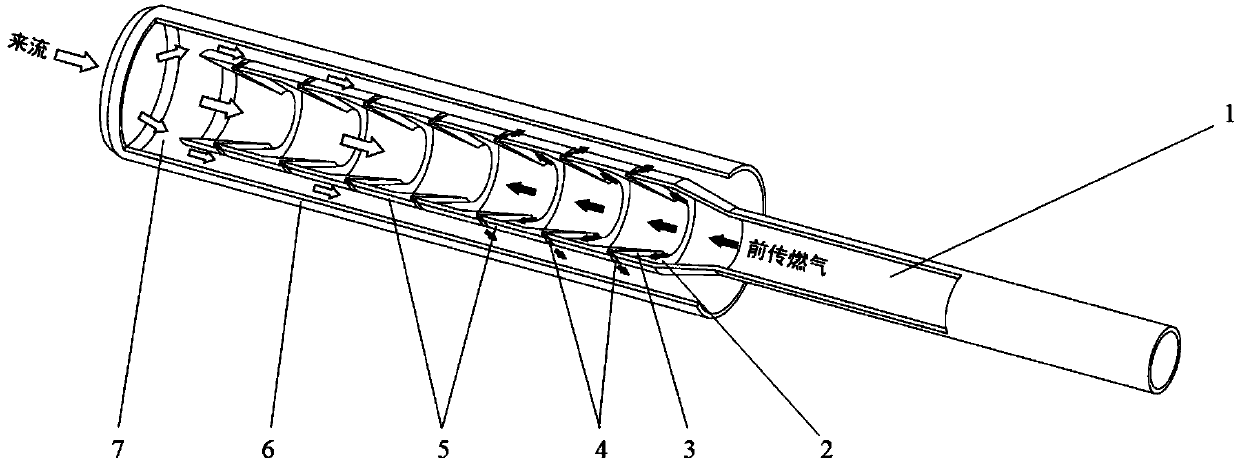

[0020] see figure 1 , figure 2 , the structure of suppressing the forward transmission of gas in the embodiment consists of a detonation combustion chamber (1), a buffer cavity (2), a thorn-shaped fin (3), a pressure relief channel (4), an inner channel shell (5), an outer channel Shell (6), air inlet (7) form. Among them, the buffer cavity (2) is a small cavity surrounded by the inner canal shell (5) and the thorn-shaped rib (3); the thorn-shaped rib (3) is in the inner canal, and its root and the inner side of the inner canal shell (5) Connected; the pressure relief duct (4) is a channel connecting the inner duct and the outer duct, and its opening position inside the inner duct shell (5) is located at the root of the thorn-shaped rib (3) and is opposite to the air inlet duct (7) The downstream side of the direction of incoming flow; the axis of the inner channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com