Pneumatic shock response spectrum tester

An impact response spectrum and testing machine technology, used in the field of pneumatic shock response spectrum testing machines, can solve the problems of inconvenient installation and maintenance, and achieve the effect of small equipment footprint, small thrust loss, and good impact repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

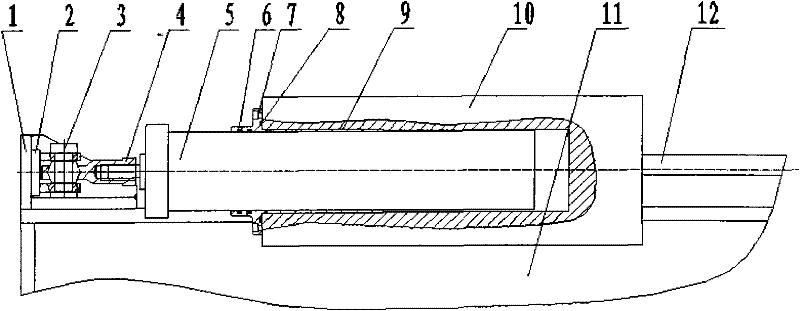

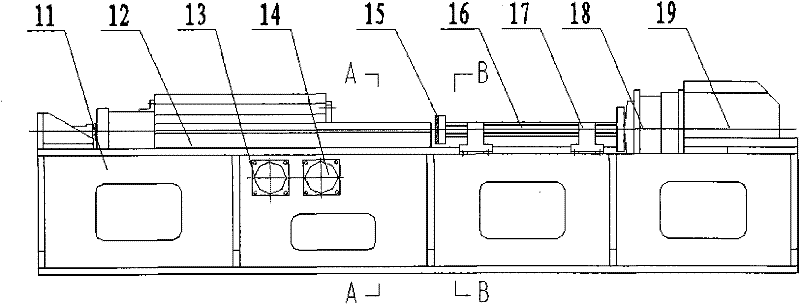

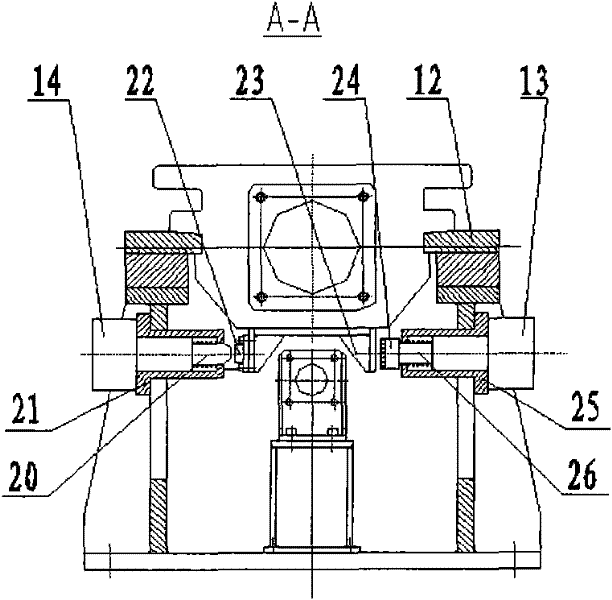

[0040] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and a preferred embodiment.

[0041] The maximum load of the pneumatic shock response spectrum testing machine in this embodiment is 200kg, the size of the resonance plate (length×width×height) is 600mm×500mm×40mm, and the weight is 135kg. The size of the hammer head (length×width) is 800mm×500mm. The hammer head is made of forged aluminum, with a weight of 200kg. The inner cavity diameter of the hammer head is 160mm, and the maximum movement stroke is 350mm. The main technical indicators that can be achieved are:

[0042] 1) Inflection point frequency: adjustable from 100 to 1500Hz;

[0043] 2) Maximum shock response spectrum peak value: 35000m / s 2 .

[0044] For testing machines with smaller load requirements, the quality of the hammer head and the diameter of the inner cavity of the hammer head can be reduced. If greater excitation force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com