A pulse detonation engine with side intake

A pulse detonation and engine technology, applied in the field of aero-engines, can solve the problems of complex inlet structure, poor mixing effect, low detonation frequency, etc., and achieve the goals of saving detonation fuel, small space resistance and increasing detonation frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described in detail below in conjunction with the examples.

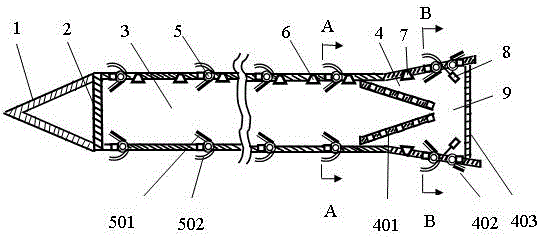

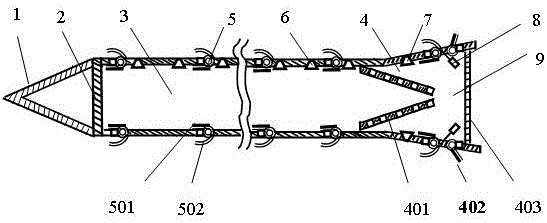

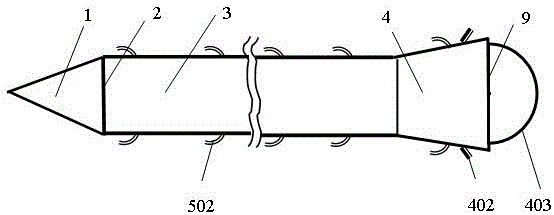

[0026] like Figure 1~6As shown, a side-intake pulse detonation engine is mainly composed of the following parts: nose cone 1, thrust wall 2, detonation chamber 3, detonation chamber 4, intake valve 5, main fuel nozzle 6, detonation fuel nozzle 7 , igniter 8 and tail nozzle 9; it is characterized in that: the nose cone 1 is located at the top of the engine, which is a hollow cone with a small cone angle, and the nose cone 1 is connected with the detonation chamber 3; the thrust wall 2 is the detonation chamber 3. The closed end plate of the head is a smooth circular plate; the detonation chamber 4 is located at the tail of the engine and shares the same space with the tail nozzle 9. The detonation chamber 4 includes an energy gathering cone 401, an exhaust valve 402 and a movable baffle 403 ; The energy-gathering cone 401 is a conical surface with a vertex towards the tail no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com