Heat pump system and control method thereof

A technology of a heat pump system and a control method, which is applied in the field of heat pumps, can solve problems such as the waste of the available range of the compressor, the size and specification of the throttling parts, and the inability of the compressor to fully realize the evaporation temperature range, so as to achieve the effect of ensuring energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

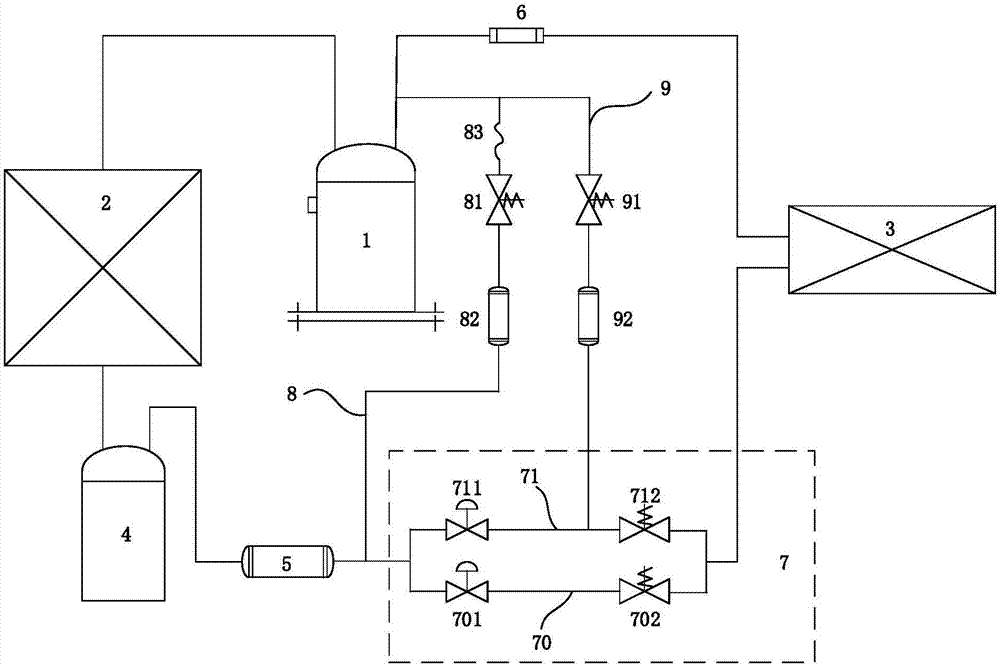

[0028] A first aspect of the present invention provides a heat pump system such as figure 1 As shown, it includes a compressor 1, a condenser 2 and an evaporator 3, wherein a throttling unit 7 is arranged on the flow path between the condenser 2 and the evaporator 3, and the throttling unit 7 includes At least two throttling branches connected in parallel, such as the first throttling branch 70 and the second throttling branch 71 shown in the figure, wherein each throttling branch is provided with a throttling component, such as the first throttling branch A first throttling component 701 is disposed in the branch path 70 , and a second throttling component 711 is disposed in the second throttling branch path 71 . Wherein, the heat pump system makes full use of the evaporation temperature range of the compressor 1 by selecting the number of throttling branches that are turned on, that is, throttling is performed by turning on a single throttling branch or making two or more th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com