Heat pump defrosting exit control method and device, electronic equipment and storage medium

A control method and heat pump technology, applied in the field of heat pumps, can solve the problems such as the decrease of heating efficiency of the unit, increase of energy consumption, failure and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

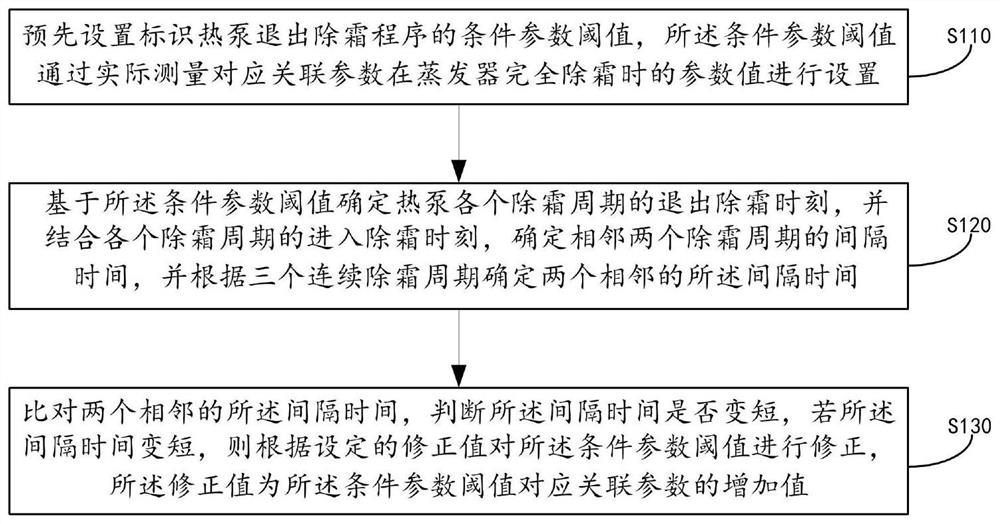

[0041] figure 1 A flow chart of a heat pump defrost exit control method provided in Embodiment 1 of the present application is given. The heat pump defrost exit control method provided in this embodiment can be executed by a heat pump defrost exit control device. The heat pump defrost exit control method The device can be realized by means of software and / or hardware, and the heat pump defrosting exit control device can be composed of two or more physical entities, or can be composed of one physical entity. Generally speaking, the heat pump defrosting exit control device may be a heat pump controller device or the like.

[0042] The following description will be made by taking the heat pump defrost exit control device as the main body for executing the heat pump defrost exit control method as an example. refer to figure 1 , the heat pump defrosting exit control method specifically includes:

[0043] S110. Preset a condition parameter threshold indicating that the heat pump ...

Embodiment 2

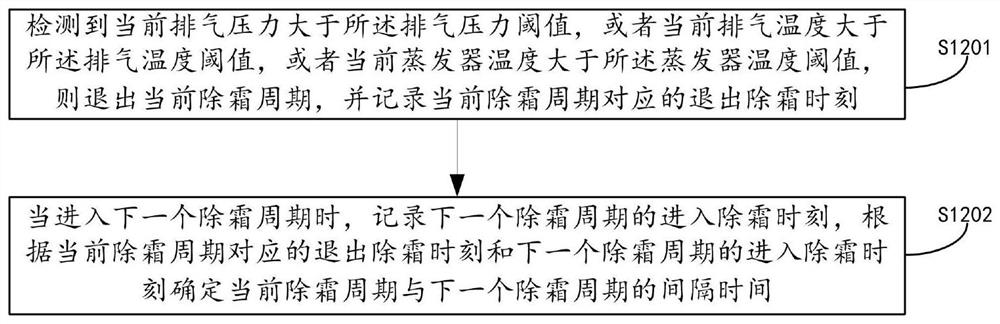

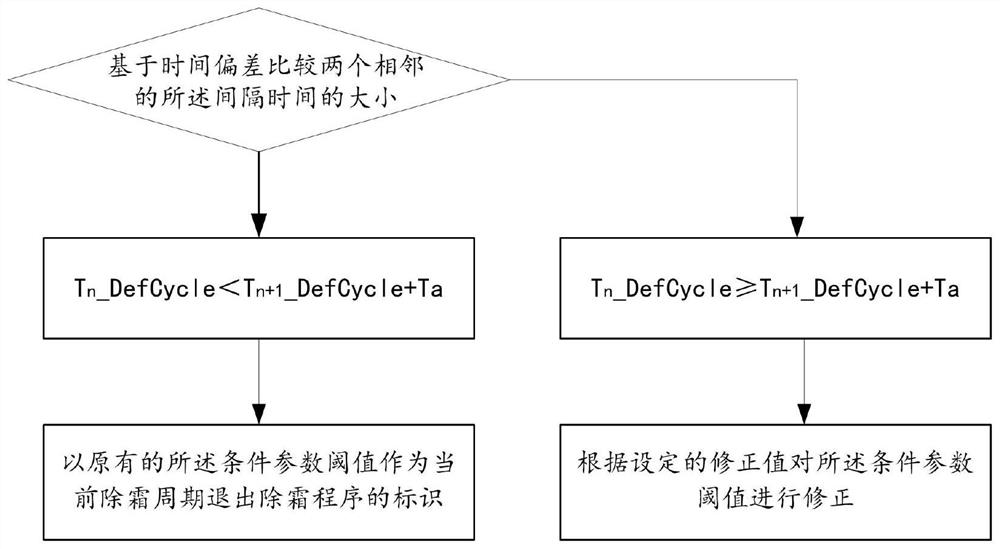

[0064] On the basis of the above-mentioned embodiment, Figure 4 This is a flowchart of another heat pump defrosting exit control method provided in the second embodiment of the present application. refer to Figure 4 , the heat pump defrosting exit control method provided by this embodiment specifically includes:

[0065] S210, preset a conditional parameter threshold that identifies the heat pump exiting the defrosting procedure, and the conditional parameter threshold is set by actually measuring the parameter value of the corresponding associated parameter when the evaporator is completely defrosted;

[0066] S220. Determine the exit defrost time of each defrost cycle of the heat pump based on the condition parameter threshold, and determine the interval time between two adjacent defrost cycles in combination with the entry defrost time of each defrost cycle, and determine the interval time between two adjacent defrost cycles according to three consecutive defrost cycles....

Embodiment 3

[0073] On the basis of the above-mentioned embodiment, Figure 5 This is a schematic structural diagram of a heat pump defrosting exit control device provided in Embodiment 3 of the present application. refer to Figure 5 , the heat pump defrosting exit control device provided in this embodiment specifically includes: a setting module 31 , a determination module 32 and a correction module 33 .

[0074] Wherein, the setting module 31 is used to preset a conditional parameter threshold that identifies the heat pump exiting the defrosting procedure, and the conditional parameter threshold is set by actually measuring the parameter value of the corresponding associated parameter when the evaporator is completely defrosted;

[0075]The determination module 32 is used to determine the exit defrost time of each defrost cycle of the heat pump based on the threshold value of the condition parameter, and determine the interval between two adjacent defrost cycles in combination with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com