Microbial fuel cell based on trimethylamine oxide medium

A trimethylamine oxide and fuel cell technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems of a large number of unfavorable microorganisms attached, narrow catalytic performance, small anode surface area, etc., to ensure proton conductivity, increase Good effect of microbial adsorption and catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

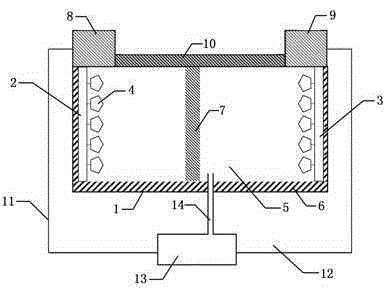

[0042] Such as Figure 1 to Figure 4 As shown, a microbial fuel cell based on trimethylamine p-oxide medium includes a reactor 1 arranged in the casing 11 and a battery positive electrode 8 and a battery negative electrode 9 arranged outside the casing 11, and the bottom of the battery positive electrode 8 is connected to the reactor 1; the bottom of the negative electrode 9 of the battery is connected to the other end of the reactor 1.

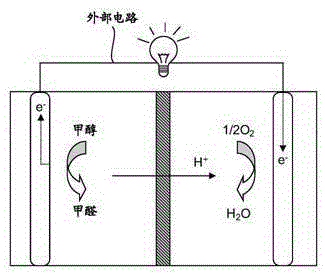

[0043] The reactor 1 includes a sealed shell 6 and an anode 2 and a negative electrode 3 arranged in the sealed shell 6, microorganisms 4 are attached to the surface of the anode 2 and the negative electrode 3, an ion exchange membrane 7 is arranged between the anode 2 and the negative electrode 3, and the anode 2 and the battery The positive pole 8 is connected, the cathode 3 is connected with the negative pole 9 of the battery, and the sealed case 6 is filled with a medium 5 .

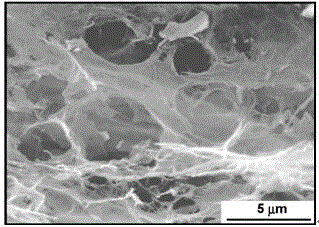

[0044] The anode 2 is surface titanium / nitrogen doped mesopor...

Embodiment 2

[0050] Anode 2—surface titanium / nitrogen doped mesoporous graphene airgel was prepared by the following steps:

[0051] Step 1: Add graphite powder and sodium nitrate to the concentrated sulfuric acid at the mass ratio of concentrated sulfuric acid: graphite powder: sodium nitrate 65:1:0.6 in an ice bath, stir and dissolve for 30 minutes, and then add graphite powder: potassium permanganate according to the mass ratio of graphite powder: potassium permanganate Ratio 1:5, add potassium permanganate to the mixed solution, stir for 10 hours, add deionized water to the mixed solution according to the volume ratio of concentrated sulfuric acid: deionized water 1:1, and place the mixture under the condition of a vacuum degree of 0.93 Slowly raise the temperature to 52°C at a rate of 1.2°C / h, keep stirring at a constant temperature of 52°C for 22 hours, then add hydrogen peroxide to the mixed solution according to the volume ratio of concentrated sulfuric acid to hydrogen peroxide (1:...

Embodiment 3

[0054] Cathode 3 - VO 2 / S-AC foam nickel air cathode is made by the following steps:

[0055] Step 1: Mix polyvinyl alcohol and polytetrafluoroethylene evenly according to the mass ratio of 1:1 and prepare a catalytic emulsion with a concentration of 10%. Mix VO2 and S-AC evenly according to the mass ratio of 2:1. Weigh the VO2 / S-AC mixture and the catalytic emulsion at a ratio of 1:3, mix the VO2 / S-AC mixture and the catalytic emulsion by ultrasonic waves for 40 minutes, heat the mixed solution to 65°C, and keep stirring for 2 hours to break the emulsion, and obtain Catalyst layer raw material;

[0056] Step 2: Press the nickel foam into a 0.6mm sheet by a tablet press, and evenly scrape the raw material of the catalytic layer on the upper surface of the foam nickel, and then microwave it for 5 minutes under the condition of a pressure of 70kPa and a power of 100W, and the surface of the sheet The excess powder is gently swept away to obtain foamed nickel covered with a ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com