Engine water-flow testing measuring device

A technology for measuring devices and water flow tests, which can be used in measuring devices, engine tests, fluid dynamics tests, etc., can solve problems such as long test periods, high test costs, and harsh test conditions, and achieve the effect of reducing development risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

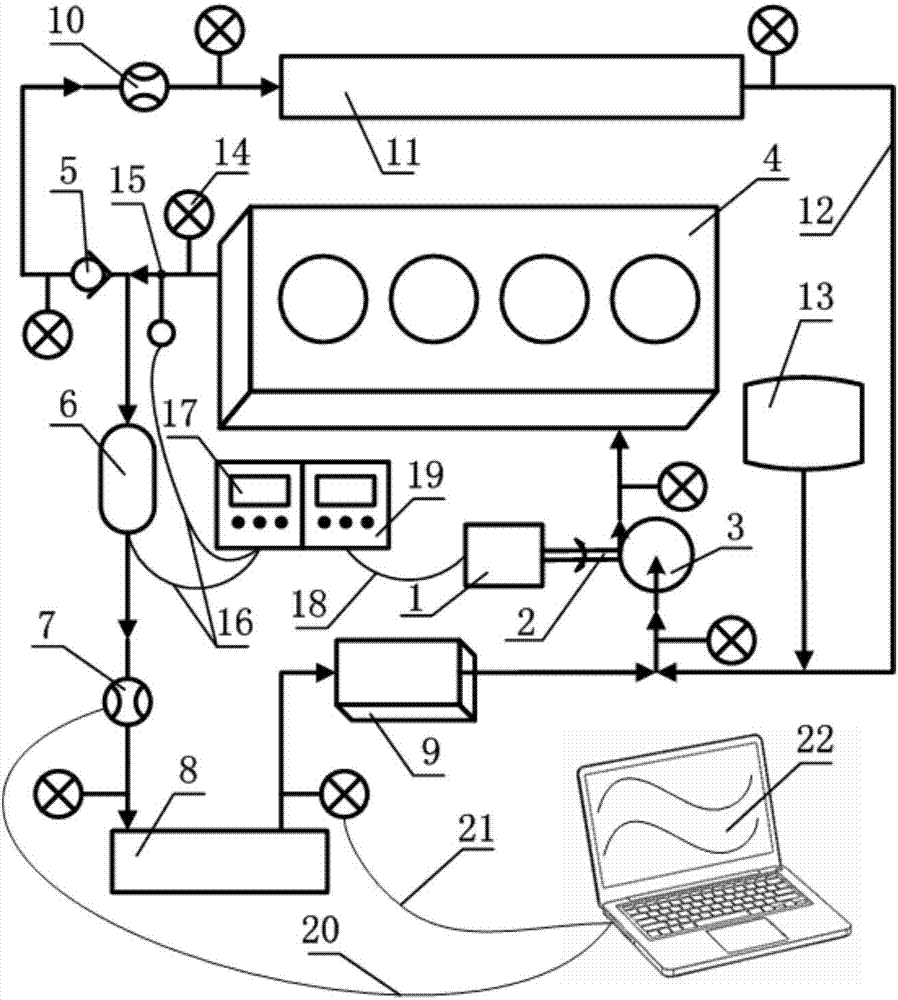

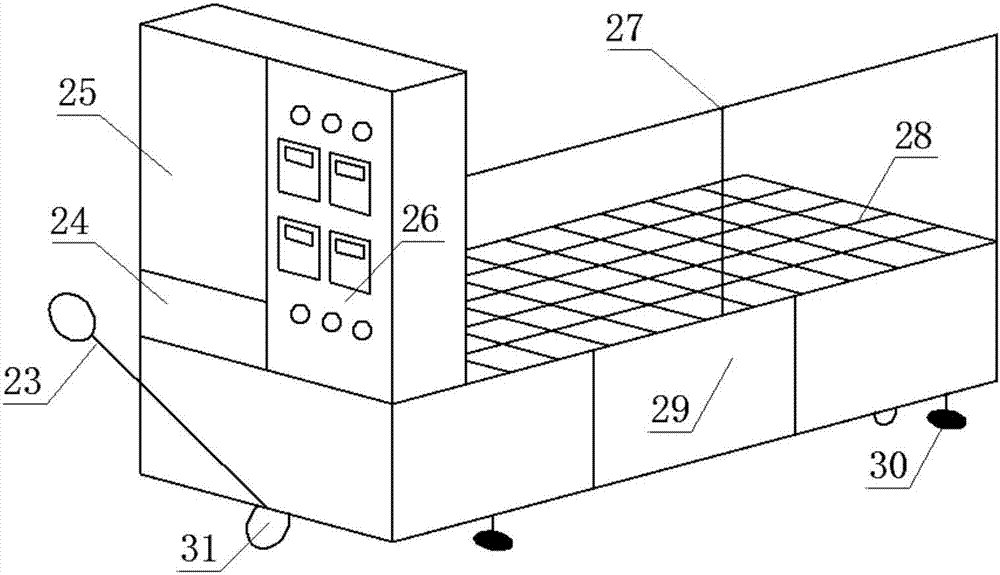

[0024] This embodiment provides an engine water flow test and measurement device, which includes a variable frequency speed regulating motor 1, a transmission mechanism 2, an engine water pump 3, an engine 4, a thermostat assembly 5, a heater 6, a first flow meter 7, a heater Wind 8, oil cooler 9, second flow meter 10, radiator 11, cooling system pipeline 12, expansion tank 13, pressure sensor 14, temperature sensor 15, temperature signal line 16, PLC heating controller 17, frequency conversion motor signal Line 18, variable frequency motor controller 19, flow signal line 20, pressure signal line 21 and data acquisition system 22.

[0025] The engine water pump, engine and radiator are arranged and connected with reference to the three-dimensional space coordinates of the real vehicle through pipelines.

[0026] The variable frequency speed regulating motor 1 is connected to the engine water pump 3 through the transmission mechanism 2, so as to drive the engine water pump 3 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com