Folding type integrally formed garment making method by using fabric one hundred percent

A folding and fabric technology, applied in the direction of sewing tools, etc., can solve the problems of many processing steps, waste of fabric, low efficiency, etc., and achieve the effect of strong personalization, no waste of fabric, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

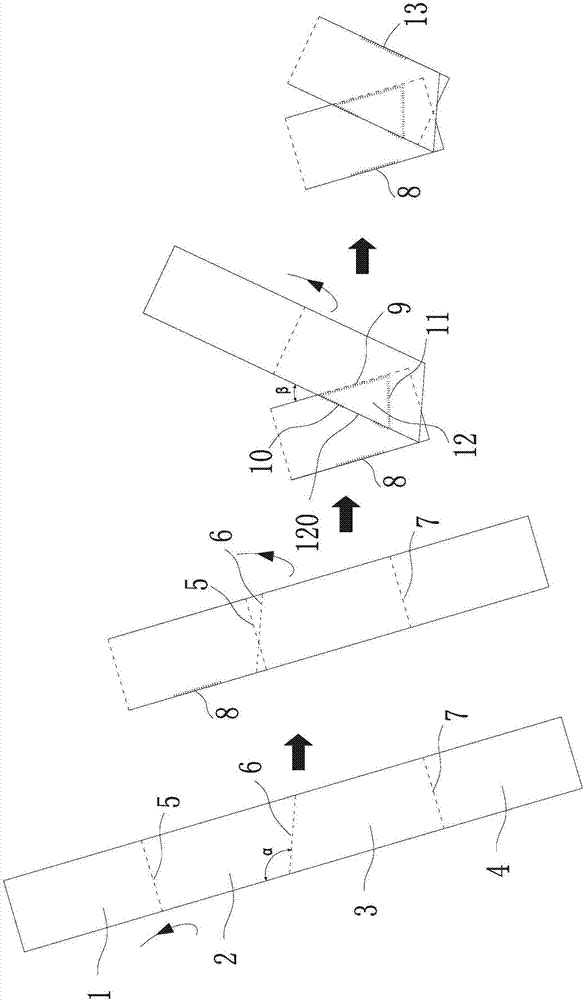

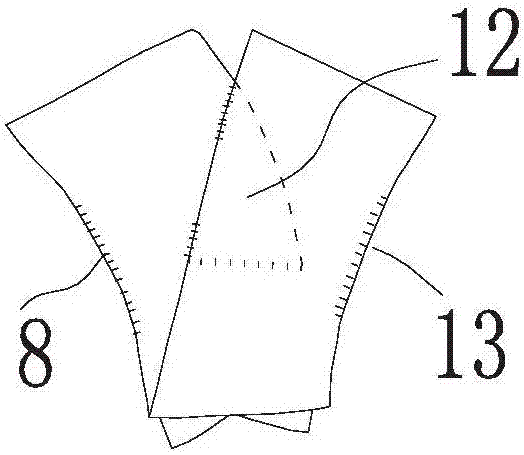

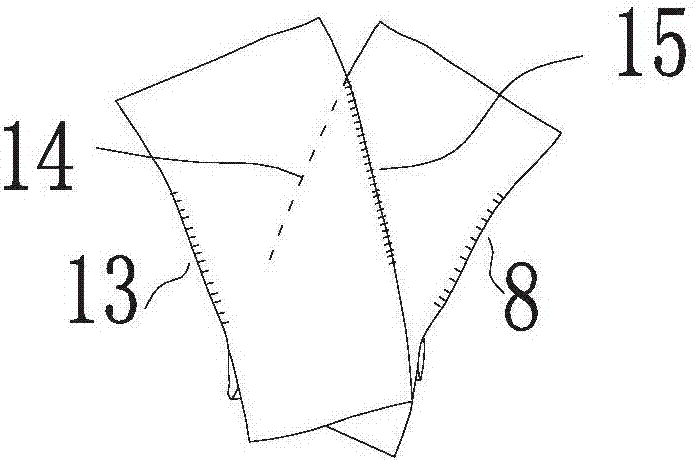

[0030] A method of folding one-piece garments that utilizes 100% of fabrics, such as Figure 1 to Figure 3 shown, including the following steps:

[0031] The first step is to cut out a piece of rectangular fabric as a whole. The length of the rectangular fabric ranges from 3.18 to 3.40 meters, and the width ranges from 0.41 to 0.43 meters;

[0032] In the second step, along the length direction of the fabric, the fabric is sequentially divided into the first folded fabric 1, the second folded fabric 2, the third folded fabric 3 and the fourth folded fabric 4 connected with each other through a plurality of straight crease lines ;

[0033] The first crease line 5 between the first folded fabric 1 and the second folded fabric 2 is perpendicular to and parallel to the length side of the fabric and runs through the entire width direction;

[0034] The angle between the second crease line 6 between the second folded fabric 2 and the third folded fabric 3 and the left side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com