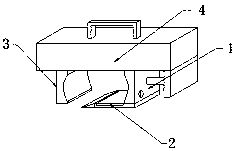

A clamp for industrial machinery

A technology of industrial machinery and clamping mechanism, which is applied in the direction of workpiece clamping device, metal processing machinery parts, clamping, etc. It can solve the problems of difficult control of clamping force, poor unloading protection, hard collision of pipelines, etc., to achieve Improve the buffer protection performance, complete functions, and avoid collision deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

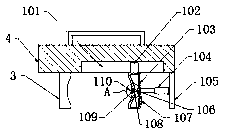

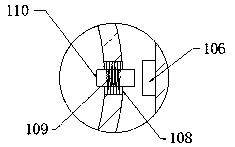

[0026] Specific implementation method: the operator first fits the pipeline with the right end surface of the fixed arc-shaped splint 3, and runs the electric telescopic rod 104. The electric telescopic rod 104 drives the movable arc-shaped splint 103 to move to the left, and the movable arc-shaped splint 103 drives the slider 102 to move to the left. Move in the chute 101, when the rubber ejector rod 110 on the movable arc-shaped splint 103 is in contact with the pipe, the pipe squeezes the rubber ejector rod 110, so that the rubber ejector rod 110 moves to the right in the guide hole 108, and the rubber ejector rod 110 simultaneously The spring 109 is elastically deformed. After the rubber push rod 110 contacts the travel switch 106, the travel switch 106 connects the circuit of the loudspeaker 107, and the loudspeaker 107 sends out an alarm sound. At this time, the movable arc splint 103 fits the pipeline, and then fixes the pipeline, thereby realizing the early warning func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com