Sawdust recovery device for plank cutting

A recycling device, technology of wood chips, applied in wood processing equipment, bark area/debris/dust/waste removal, manufacturing tools, etc., can solve the problem that wood chips cannot be recycled separately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

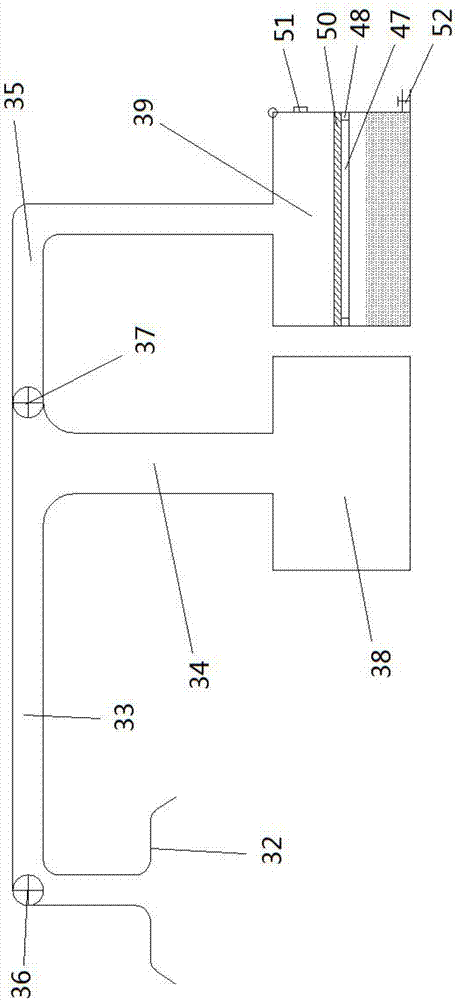

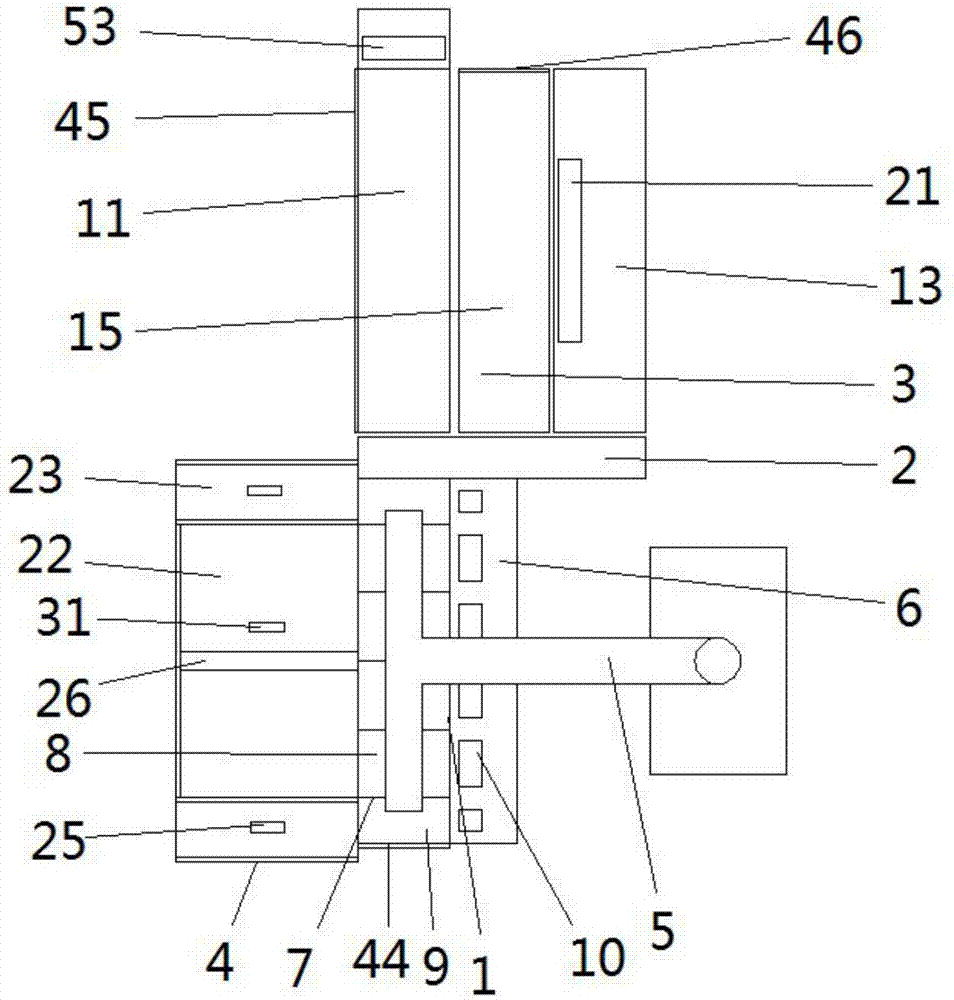

[0015] Embodiment: the sawdust recovery device that plank cutting is used, structure such as figure 1 As shown, the dust collection cover 32 is included, the dust collection cover 32 is respectively connected with the first branch 34 and the second branch 35 through the main pipeline 33, the first negative pressure fan 36 is arranged in the main pipeline 33, and the second branch 35 A second negative pressure blower 37 is provided inside, a wood recovery box 38 is connected under the first branch 34 , and a wood chip recovery box 39 is connected under the second branch 35 .

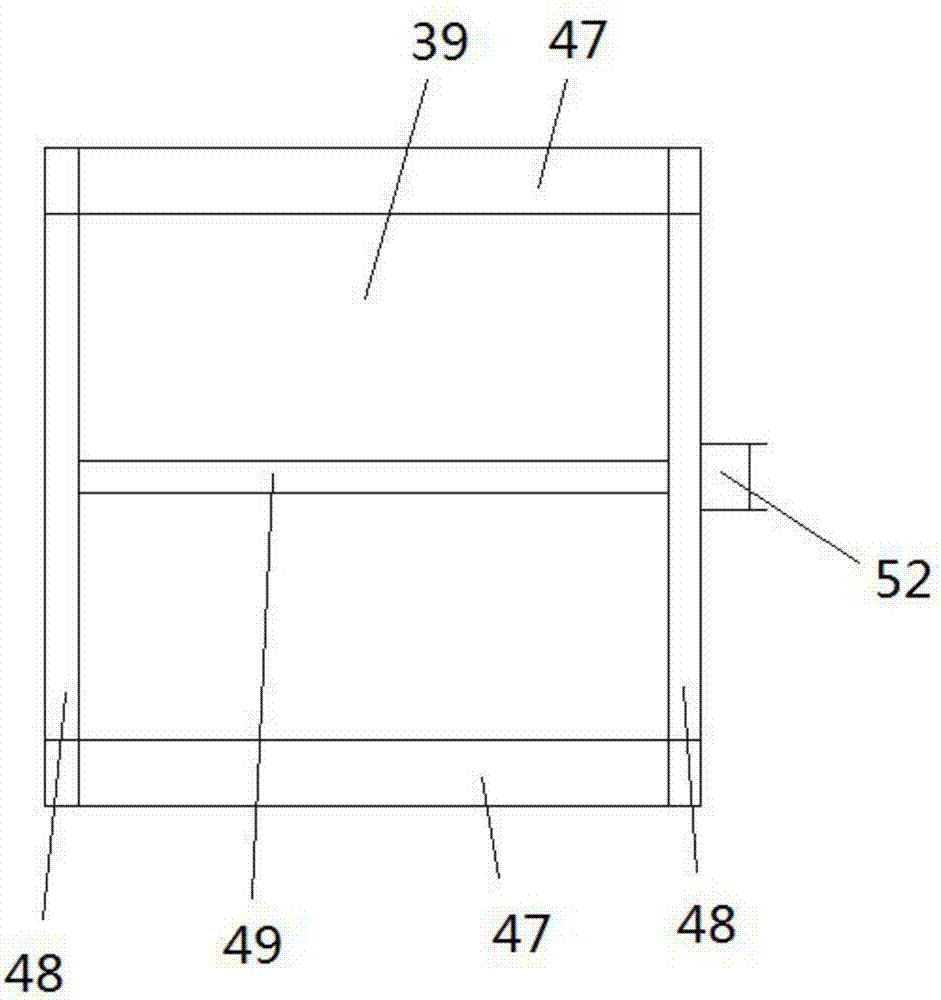

[0016] The top view of described sawdust recovery box 39 is as figure 2 As shown, the inwall of the sawdust recovery box 39 is provided with a slide track 47, and a slide bar 48 is respectively provided at both ends of the slide track 47, and the two slide bars 48 are connected by a connecting rod 49, and the slide bar 48 is provided with a dust filter. The net 50 and the upper side wall of the sawdust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com