Safety production informatization inspection system and method thereof

A technology for safety production and inspection methods, applied in the field of safety production information inspection systems, can solve problems such as large response, statistical analysis, and dependence on inspection results, and achieve the effect of improving efficiency and easy statistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0054] figure 1 It is a schematic diagram showing the hardware structure of the production safety informatization inspection system according to the first embodiment of the present invention. Such as figure 1 As shown, the safety production informatization inspection system 10 involved in the first embodiment of the present invention includes: a central terminal 1, an enterprise client 2, a security officer client 3, an expert client 4, a network 5, a central terminal 1, an enterprise The client 2, the security officer client 3, and the expert client 4 are respectively connected to the network 5. Among them, the center terminal 1 is usually a server, which can be installed in the Work Safety Bureau (or the State Work Safety Administration), etc., and can have multiple databases. The enterprise client 2 is installed in the enterprise for the enterprise to make reservations for security checks and receive other messages pushed by the center 1. It can be a fixed terminal such a...

Embodiment 1

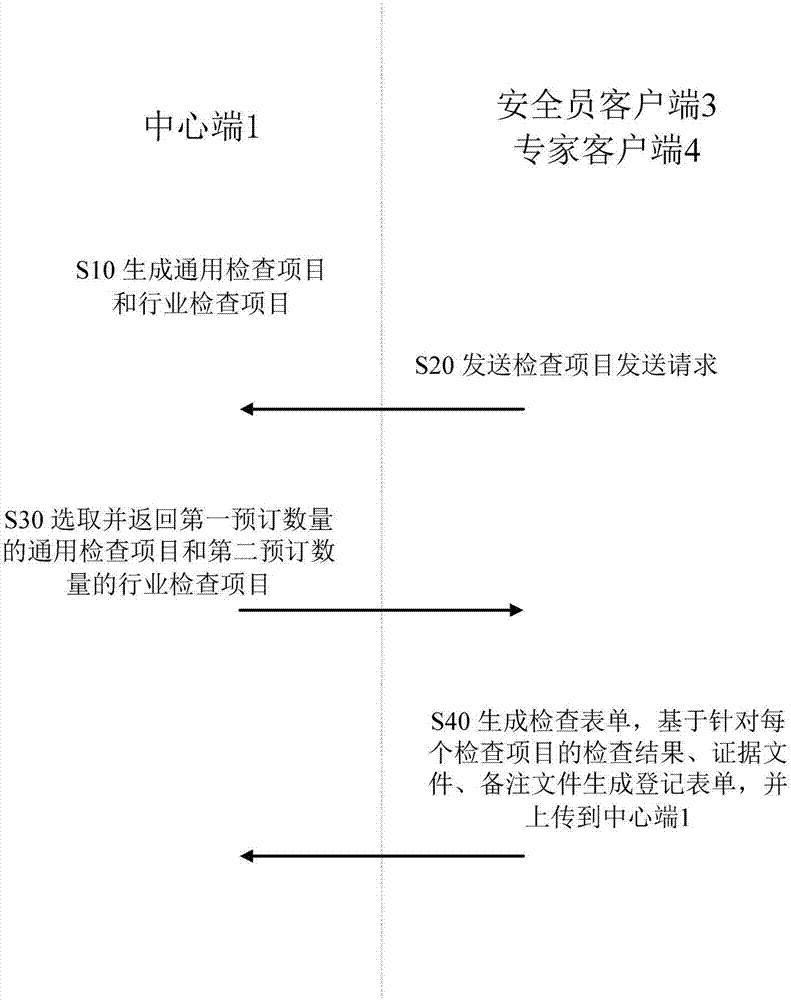

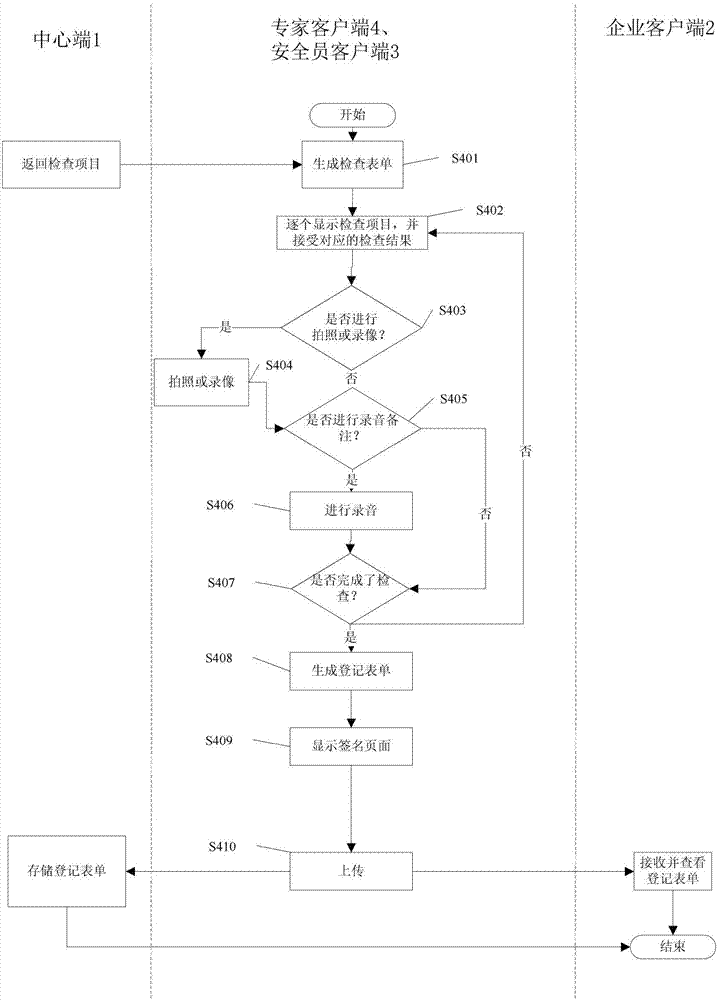

[0056] Below, refer to the attached figure 2 , the production safety informatization inspection method according to Example 1 of the first embodiment of the present invention will be described. The inspection method for production safety informatization includes steps S10-S40. Here, since the person who goes to the enterprise site to conduct the security inspection may be a security officer or an expert, the client that generates the inspection form and uploads the inspection result (registration form) (equivalent to the "first client" in the claims) It can be the security officer client 3 or the expert client 4.

[0057] In step S10, inspection items are generated. Specifically, the central terminal 1 extracts items commonly used in various industries from the standards related to production safety to generate general inspection items, and stores the general inspection items in the general database of the central terminal 1. Items related to hidden dangers in the industry...

Embodiment 2

[0072] Below, refer to the attached Figure 4 , the production safety informatization inspection method according to Example 2 of the first embodiment of the present invention will be described. Embodiment 2 is a situation in which an expert is reserved through the security officer client terminal 3, and the expert is asked to provide safety production inspection services for the enterprise. In addition to the above-mentioned steps S10-S40, the method for inspecting production safety informatization in Embodiment 2 may further include steps S50-S60.

[0073] In step S50, an expert group is created. Specifically, the center terminal 1 assigns experts to each sub-area in the target area according to the position and category of the experts, and sends an inquiry including the service time period to the expert client 4 of multiple experts assigned to each sub-area Information, and based on the selection result returned by the expert client 4, create an expert group that provides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com