Instrument mounting box of instrument supporting device

An installation box and support technology, applied in the field of instruments, can solve the problems of fixed installation position of the instrument, inconvenient instrument observation, inability to realize multi-angle adjustment of the instrument, etc., and achieve the effect of tightening installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

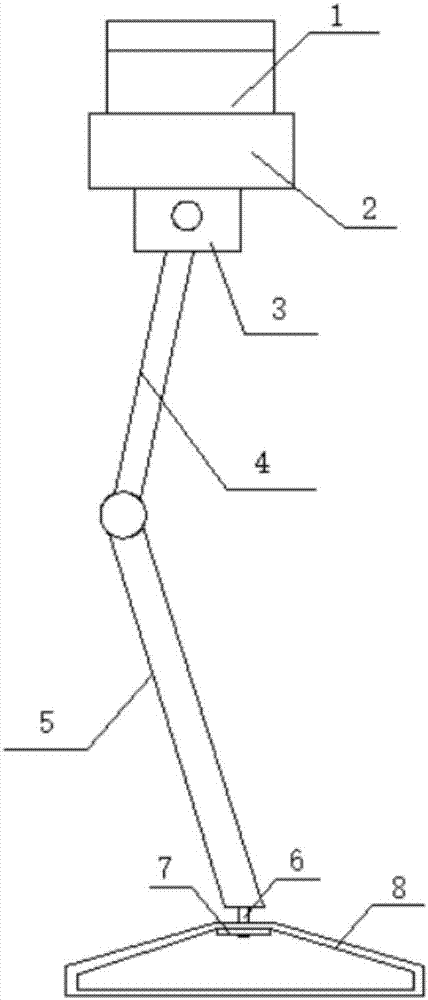

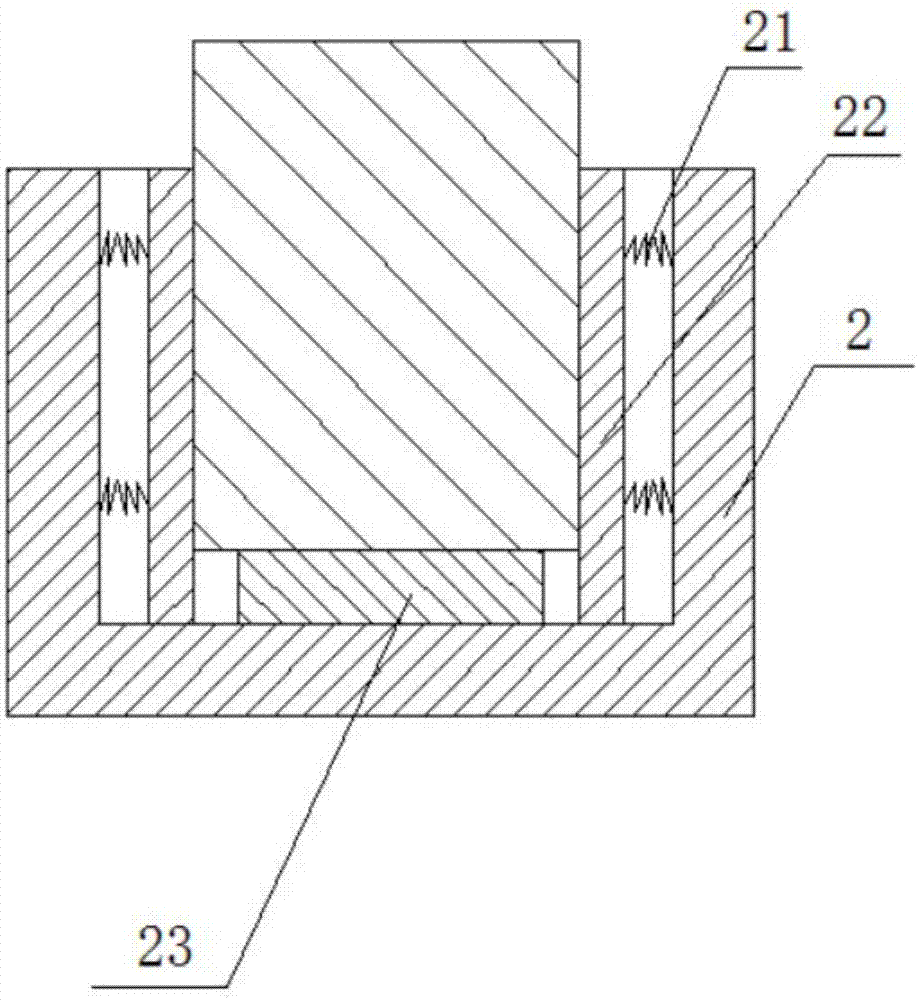

[0033] Such as Figure 1 to Figure 2 As shown, the present invention provides an instrument supporter, comprising: an instrument installation box 2, a bearing block 3, a first support rod 4, a second support rod 5, bolts 6, gaskets 7 and a base 8; the instrument installation box 2 is used to install the instrument 1; the bearing block 3 is arranged at the bottom of the instrument installation box 2; one end of the first support rod 4 is rotatably connected to the bearing block 3, and the other end of the first support rod 4 One end is rotationally connected with one end of the second support rod 5, the other end of the second support rod 5 is provided with the bolt 6; the top of the base 8 is provided with a through hole, and the bolt 6 passes through the through hole. One end of the bolt 6 passing through the through hole is threadedly connected with the gasket 7; the instrument installation box 2 is provided with a spring 21 opposite to the two inner walls, and the deformati...

Embodiment 2

[0036] A method for manufacturing an instrument installation box of an instrument supporter, the steps are as follows:

[0037] ①. The structure and molding of the instrument installation box

[0038] The opposite inner walls of the instrument installation box are provided with springs, and the deformation direction of the spring is perpendicular to the side wall of the instrument installation box; the spring is provided with an extrusion plate, which is parallel to the side wall of the instrument installation box, and the extrusion plate It is used to install the instrument; there is a pad at the bottom of the instrument installation box;

[0039] The material of the instrument installation box is stainless steel, which is welded by stainless steel plates; the material of the extrusion plate is foam rubber sponge; the material of the spring is carbon spring steel wire; the material of the pad is foam rubber sponge;

[0040] ②. Pretreatment of extruded plates and pads

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com