Method for treating ultrahigh-hardness and ultrahigh-conductivity waste water

A high-conductivity, conductivity technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Low operating cost, low conductivity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

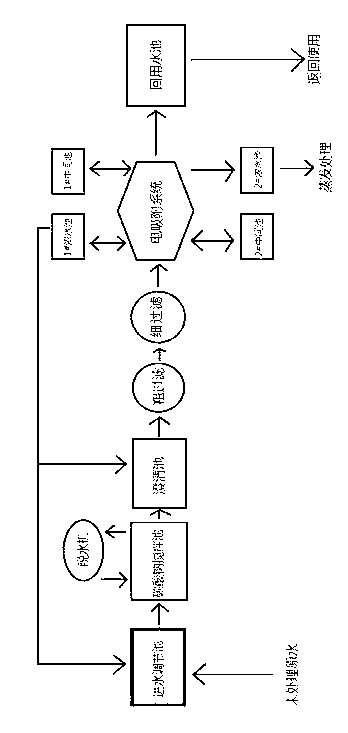

[0041] Such as figure 1 Shown, the method for processing extra-high hardness extra-high conductivity waste water of the present invention is carried out as follows:

[0042] step one:

[0043] Mix all kinds of wastewater into the adjustment tank for 15-20 minutes and then test the total hardness of the water. When the total hardness is <550 mg / L and the pH value is 7.5-11, it can directly enter step 2 for treatment. If the total hardness is ≥550 mg / L , introduce the water into the sodium carbonate stirring tank, add sodium carbonate to the water and stir for 20-35 minutes until the total hardness of the water is <550 mg / L, (after adding sodium carbonate, a large amount of calcium carbonate will be generated in the water), precipitation 3-6 hours, the supernatant after precipitation enters step 2 for treatment, and the rest of the calcium carbonate-containing sludge is pumped to the sludge dewatering machine for solid-liquid separation, and the separated water returns to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com