Ignition device of gas-heating water heating furnace

An ignition device and gas heating technology, applied in the directions of combustion ignition, ignition using electric sparks, combustion methods, etc., can solve the problems of lack of service life of ignition needles, inability to be disassembled and replaced separately, and high cost of replacement of parts, saving resources, reducing The effect of configuration cost and lower replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

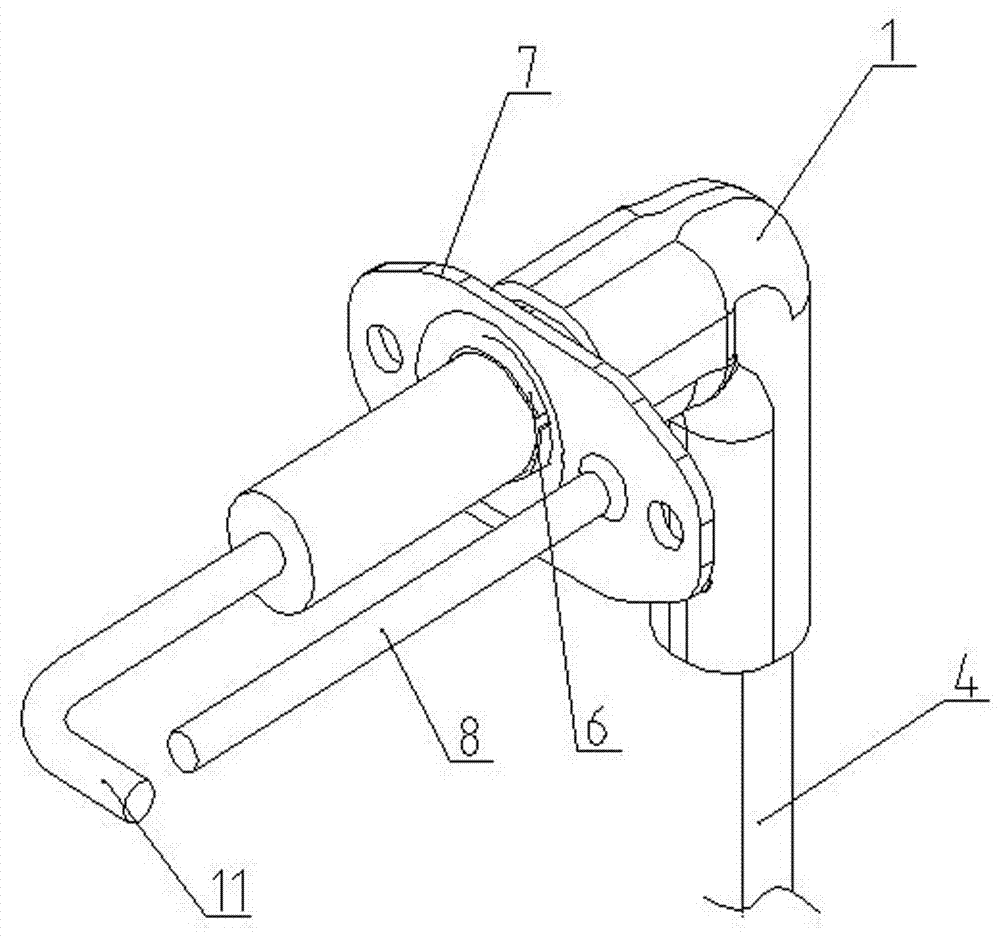

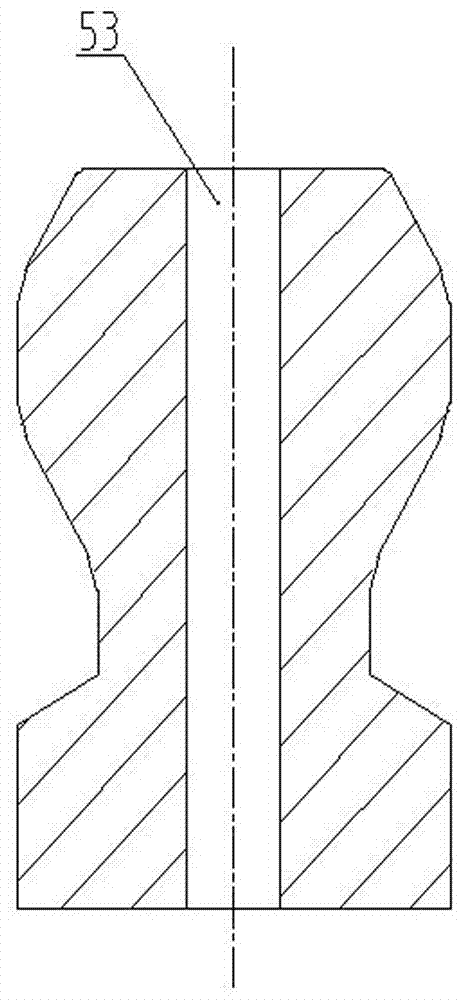

[0021] like figure 1 , figure 2 As shown, the ignition device of the gas heating water heater disclosed in this embodiment includes a sheath 1, an arc shrapnel 2, a connection terminal 3, a connecting wire 4, a terminal joint 5, a spring washer ring 6, and a mounting positioning plate 7 , Grounding pin 8,, grounding insert 9, ceramic rod 10, ignition pin 11.

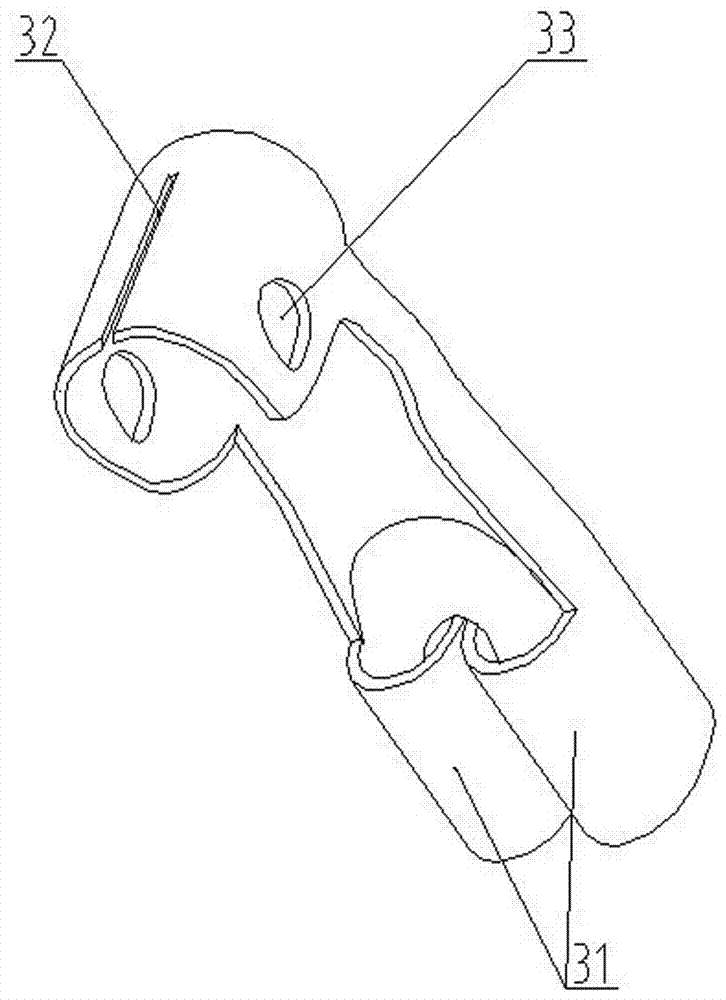

[0022] like image 3 As shown, the connecting terminal 3 is an elbow-shaped terminal head, one end of which is a connecting end, and the other end is a connecting end of a terminal joint. There are strip-shaped blind grooves 32 to make the arc-shaped cover elastic.

[0023] from figure 1 It can be seen that the connecting wire 4 connected to the pulser passes through an inwardly curved sleeve at the terminal of the terminal 3, and is bent back and inserted into another inwardly curved sleeve for positioning. That is to say, the joint of the connecting wire is bent into an "n" shape, and the connecting wire is press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap