Drive bearing assembly method and sleeve for assembling drive bearing

A technology of driving bearings and assembly methods, which is applied in the direction of shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of easy falling of residues, easy damage of driving bearings, and reduced service life of driving bearings, so as to save manpower and prolong use Long life, achieve the effect of non-destructive installation

Active Publication Date: 2019-10-01

CNR LANZHOU LOCOMOTIVE

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This knocking operation makes the residue on the copper rod easy to fall into the drive bearing, which will cause the drive bearing to be easily damaged and reduce the service life of the drive bearing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

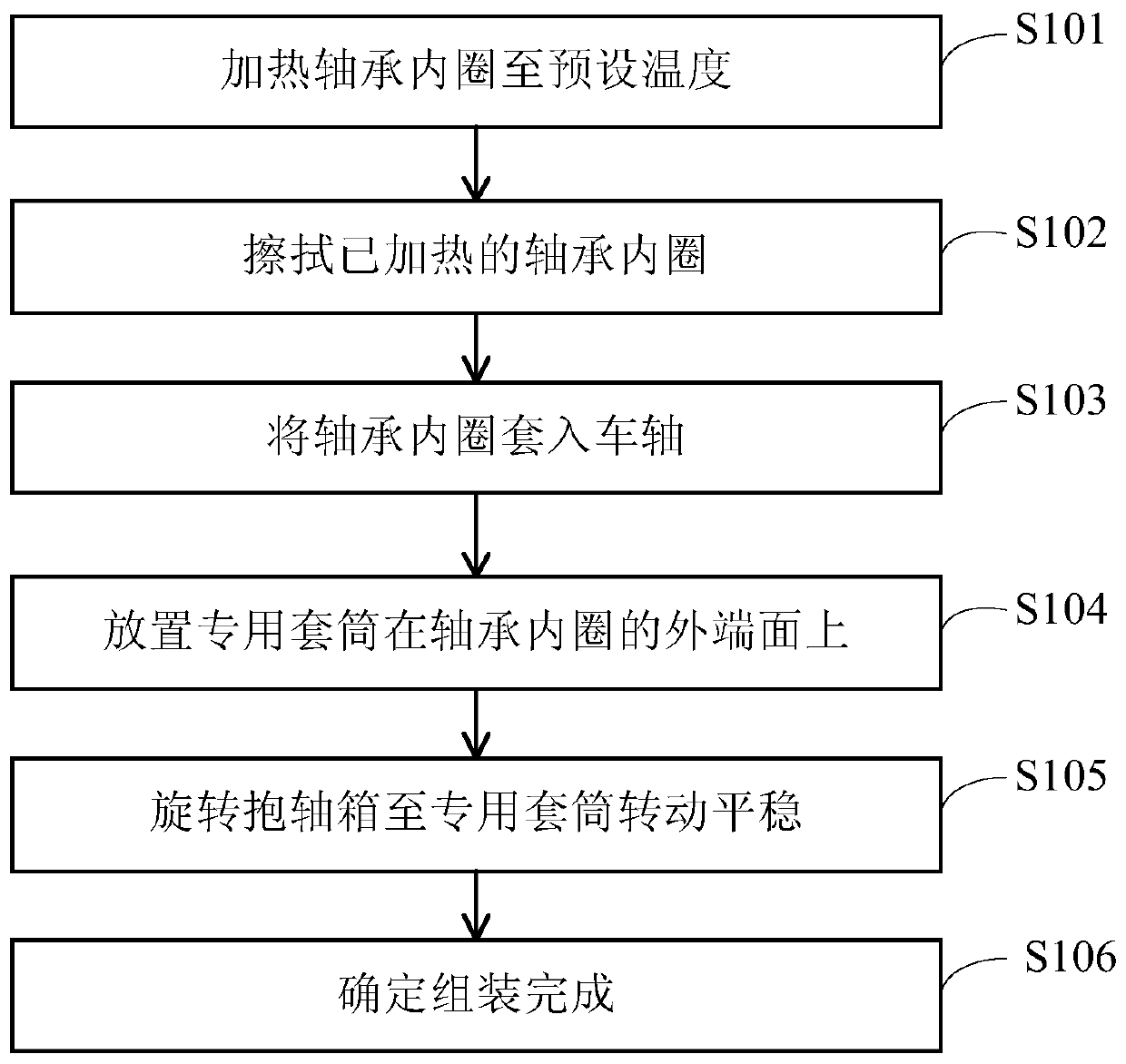

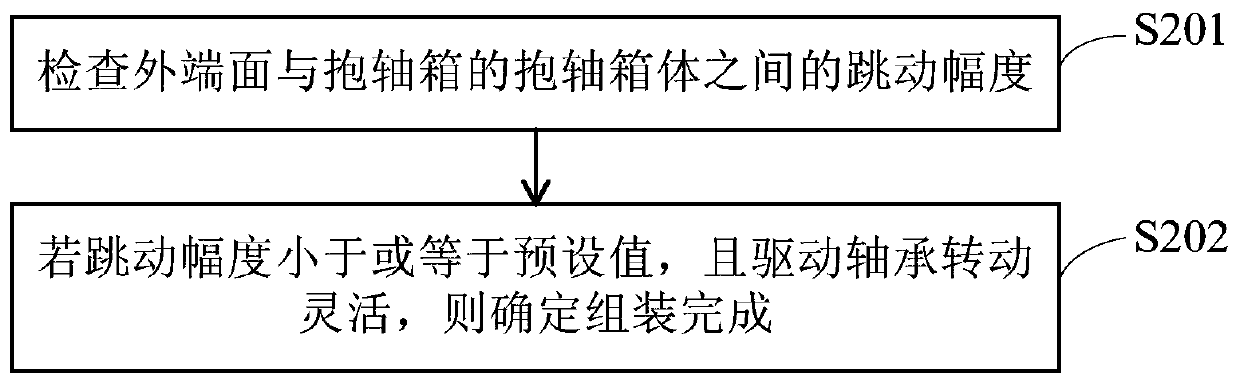

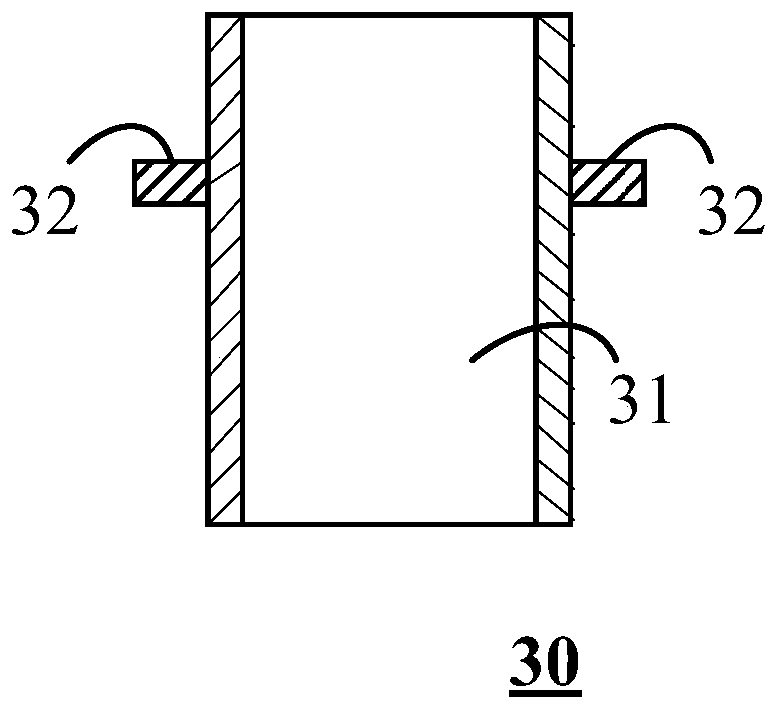

The invention provides a driving bearing assembly method and a special sleeve for assembling a driving bearing. The driving bearing assembly method comprises the following steps: a bearing inner ring is heated to reach a preset temperature; the heated bearing inner ring is wiped; the bearing inner ring is sleeved in an axle; the special sleeve is placed on the outer end surface of the bearing inner ring; a rotary shaft holding box is stably rotated to the special sleeve; and the assembly is finished. The driving bearing assembly method can realize lossless assembly of the driving bearing, and prolongs the service life of the driving bearing.

Description

technical field The invention relates to assembly technology, in particular to a driving bearing assembly method and a sleeve used for assembling the driving bearing. Background technique Drive bearing, as an important part of the locomotive, its assembly method is very important. In the prior art, in the process of assembling the driving bearing, copper rods need to be used to knock the large end cover several times, wherein the large end cover is arranged on the inner end surface of the inner ring of the bearing. This knocking operation makes the residue on the copper rod easily fall into the inside of the drive bearing, thereby causing the drive bearing to be easily damaged and reducing the service life of the drive bearing. Contents of the invention The invention provides a driving bearing assembly method and a sleeve used for assembling the driving bearing, so as to realize the non-destructive assembly of the driving bearing and prolong the service life of the driv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16C43/04

Inventor 孙广王怀玉黄兵亮肖永峰张宏声韩静

Owner CNR LANZHOU LOCOMOTIVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com