A Tractor Driving Robot Based on Force/Position Hybrid Control

A hybrid control, tractor technology, applied in mechanical control devices, control/regulation systems, instruments, etc., can solve the problems of low positioning accuracy, large volume, low transmission efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

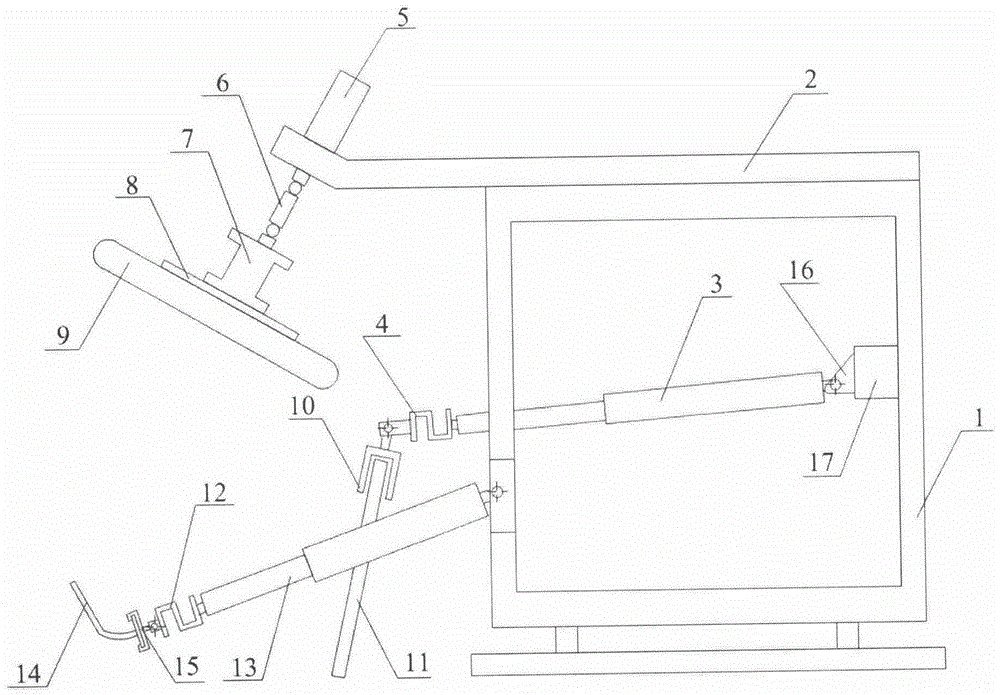

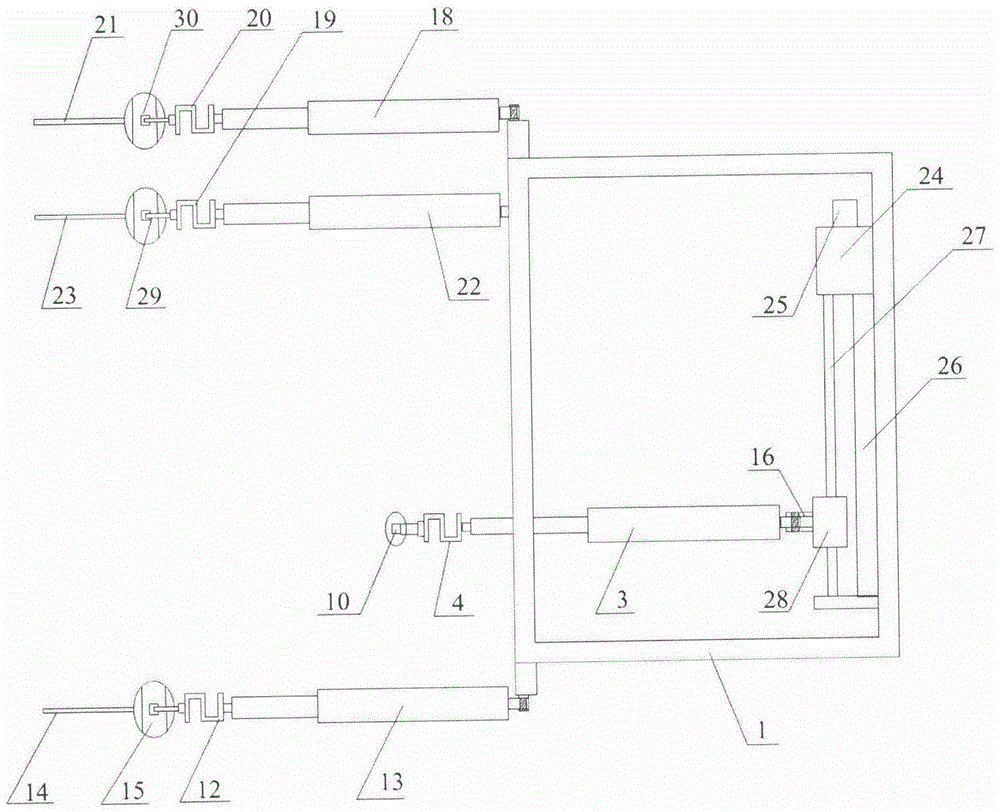

[0019] Example: such as figure 1 and figure 2 Shown:

[0020] A tractor driving robot based on force / position hybrid control, comprising a base 1, an accelerator mechanical leg, a braking mechanical leg, a clutch mechanical leg, a shifting manipulator, and a steering manipulator, characterized in that the base 1. It is fixed above the driving seat of the tractor. The front end of the base 1 is respectively connected to the throttle mechanical leg, brake mechanical leg, and one end of the clutch mechanical leg through bearings from right to left. The accelerator mechanical leg, brake mechanical leg, and clutch mechanical leg The other end of the leg is connected in rotation with the accelerator pedal 21, the brake pedal 23, and the clutch pedal 14 of the tractor, one end of the shift manipulator is fixedly connected with the base 1, and the shift handle cover 10 at the other end of the shift manipulator is inserted into the tractor shift lever. 11 end, and is slidingly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com