Waterborne polymer cement-based waterproof coating and preparation method thereof

A technology of water-based polymers and waterproof coatings, applied in cement coatings, coatings, etc., can solve the problems of unsatisfactory cement strength and poor waterproof performance, and achieve the goal of improving wideness, enhancing outdoor durability, long decoration and waterproof functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation of the liquid material component at least includes the following steps:

[0036] Weigh each component according to the above-mentioned raw material ratio;

[0037] First, add water into the first reactor, add 50wt% thickener at a speed of 400-600rpm, disperse at a speed of 1000-1200rpm for 20-25min, and then add a dispersant and a defoaming agent;

[0038] At the rotating speed of 700-900rpm, add titanium dioxide to the first reactor, and disperse to the fineness≤55um at the rotating speed of 1000-1200rpm;

[0039] Under the rotating speed of 400-600rpm, add fluorocarbon emulsion, film-forming aids, antiseptics, ultraviolet absorbers, and remaining thickeners to the first reactor, and adjust the viscosity to 70-75KU to obtain the liquid material components;

[0040] The preparation of the powder component at least includes the following steps:

[0041] Weigh each component according to the above-mentioned raw material ratio;

[0042] Add 50wt% of cem...

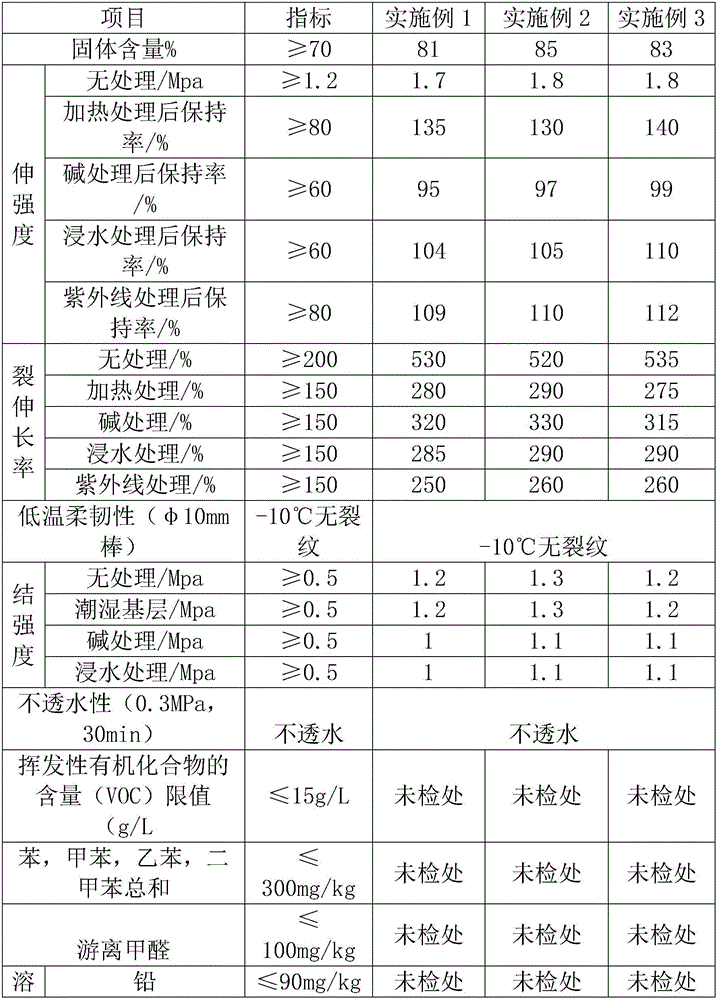

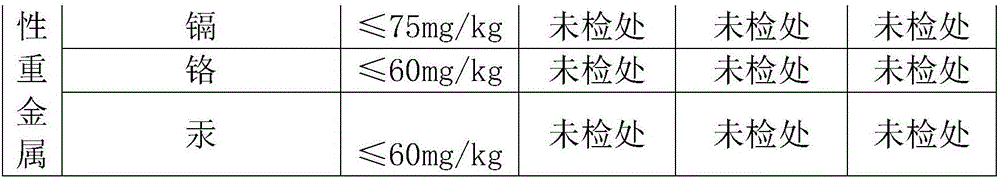

Embodiment 1

[0047] The present embodiment provides a water-based polymer cement-based waterproof coating, the mass ratio of the liquid material to the powder is 1:3.5;

[0048] The liquid material component is composed of the following components in terms of weight percentage: fluorocarbon emulsion: 55%, titanium dioxide: 7%, film-forming aid: 4%, dispersant: 0.2%, defoamer: 0.1% %, preservatives: 0.1%, UV absorbers: 0.6%, thickeners: 0.5%; water: 32.5%;

[0049] The powder component is composed of the following components in terms of weight percentage: cement: 50%, quartz sand: 35%, heavy calcium: 14%, cellulose ether: 0.5%, water reducer: 0.4%, poly Acrylic fibers: 0.1%.

[0050] The preparation method of above-mentioned waterborne polymer cement-based waterproof coating comprises the following steps:

[0051] Take each component according to the above-mentioned raw material ratio;

[0052] Firstly add water into the reactor, add 50wt% thickener at the speed of 400-600rpm, disperse a...

Embodiment 2

[0061] This embodiment provides a water-based polymer cement-based waterproof coating, the mass ratio of the liquid material to the powder is 1:3;

[0062] The liquid material component is composed of the following components in terms of weight percentage: fluorocarbon emulsion: 50%, titanium dioxide: 10%, film-forming aid: 3%, dispersant: 0.3%, defoamer: 0.2% %, preservatives: 0.2%, UV absorbers: 0.9%, thickeners: 1%; water: 34.4%;

[0063] The powder component is composed of the following components in terms of weight percentage: cement: 40%, quartz sand: 40%, heavy calcium: 18.5%, cellulose ether: 1%, water reducing agent: 0.45%, poly Acrylic fibers: 0.05%.

[0064] The preparation method and application method of the above-mentioned water-based polymer cement-based waterproof coating are as described in Example 1, and will not be repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap