Polyaspartic acid ester craft paint and preparation method and application thereof

A technology of polyaspartic and handicrafts, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of production enterprises, such as difficulty in processing and cost increase, unsatisfactory product quality and coating, and products that have not been improved and upgraded. Achieve the effect of enhanced scratch resistance, enhanced transparency and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Main ingredient:

[0092] 1420 polyaspartic acid ester resin 69.0

[0093] 615S Dispersant 4.0

[0094] HM1190 high pigment carbon black 5.2

[0095] SPX-35 defoamer 0.4

[0096] 3000 mesh glass powder 6.0

[0097] 5A absorbent powder 4.0

[0098] EV81 UV absorber 1.5

[0099] EV93 UV absorber 1.5

[0100] 360S leveling agent 0.6

[0101] Xylene 5.0

[0102] Butyl propionate 2.0

[0103] Ethylene glycol butyl ether acetate 0.8

[0104] hardener:

[0105] HI100 toluene diisocyanate 75.0

[0106] SP103S Isophorone diisocyanate 10.0

[0107] TI water absorption stabilizer 0.3

[0108] Butyl propionate 12.0

[0109] Ethylene glycol butyl ether acetate 2.7

[0110] Solvent:

[0111] Xylene 55.0

[0112] Butyl propionate 25.0

[0113] Heptanone 5.0

Embodiment 2

[0116] Main ingredient:

[0117] F421 polyaspartic acid ester resin 72.0

[0118] EFKA4060 dispersant 5.7

[0119] HM1190 high pigment carbon black 5.7

[0120] 130S defoamer 0.5

[0121] 3000 mesh glass powder 5.0

[0122] 5A absorbent powder 3.0

[0123] EV81 UV absorber 1.0

[0124] EV93 UV absorber 1.0

[0125] 360S leveling agent 0.5

[0126] Xylene 4.0

[0127] Butyl propionate 1.0

[0128] Ethylene glycol butyl ether acetate 0.6

[0129] hardener:

[0130] HI100 toluene diisocyanate 77.8

[0131] SP103S Isophorone Diisocyanate 8.0

[0132] TI water absorption stabilizer 0.2

[0133] Butyl propionate 11.0

[0134] Ethylene glycol butyl ether acetate 3.0

[0135] Solvent:

[0136] Xylene 55.0

[0137] Butyl propionate 25.0

[0138] Heptanone 5.0

[0139] Ethylene glycol butyl ether acetate 15.0

Embodiment 1-2

[0140] The preparation method of embodiment 1-2:

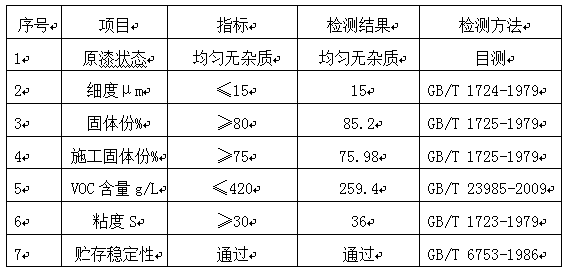

[0141]Stir the resin, dispersant, carbon black, defoamer, wear-resistant powder, water-absorbing powder, and some solvents evenly, and then stir evenly after standing for 24 hours. Grind the paint base to the required fineness, add UV absorbers, leveling agents and solvents according to the test data of the paint base, stir the paint liquid evenly and spray to test the performance, filter and pack after the performance is qualified; the solvents mentioned are: Xylene, butyl propionate, and ethylene glycol butyl ether acetate are mixed and added in a ratio of 25:10:4. The fineness mentioned here refers to the maximum particle size of the particles in the color paste, which requires ≤15μm.

[0142] Main agent: hardener: solvent=100:65:10

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com