Curtain brake head

A technology for making curtains and head seats, which is applied to windows/doors, door/window protection devices, building components, etc., and can solve problems such as reducing production efficiency, increasing production costs, and the impact of head-making weight, so as to improve production efficiency, Reduce the requirement of precision and stabilize the effect of braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

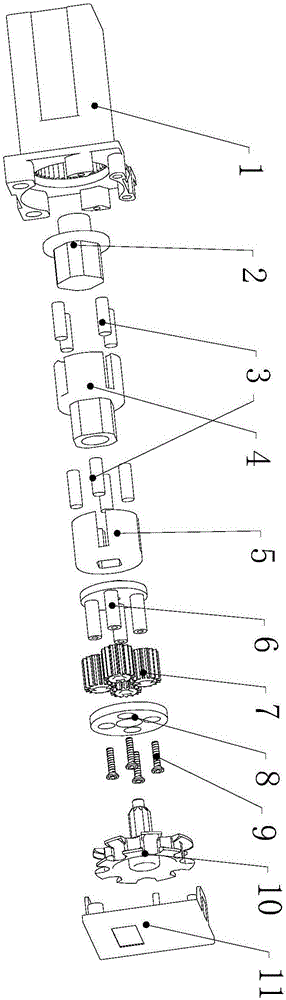

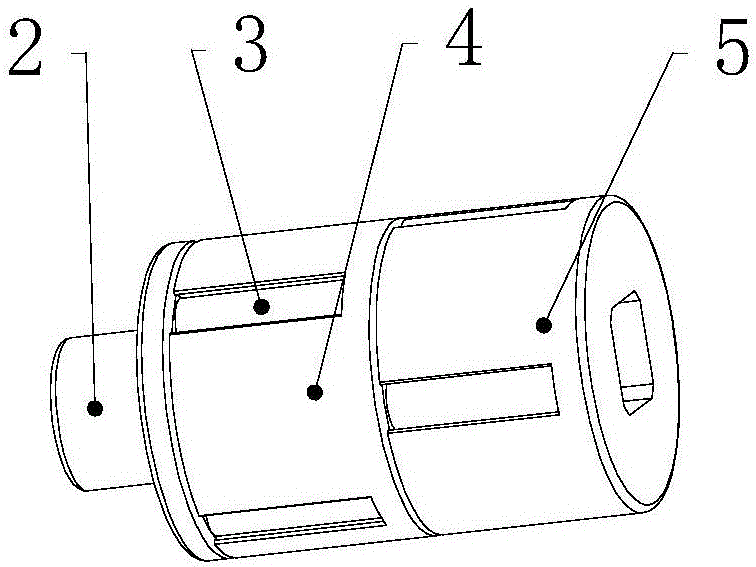

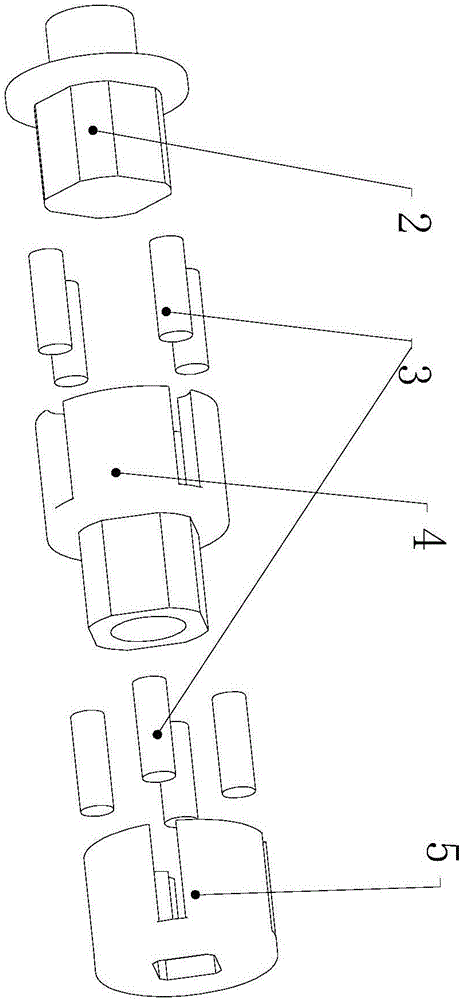

[0020] refer to Figure 1 ~ Figure 4 , the present invention is a head-making base 1 and a head-making cover 11 connected with the head-making base, an inner chamber is provided in the head-making base 1, a sprocket 10 is arranged in the inner cavity, and one end of the sprocket 10 is connected with the manufacturing head. The head cover 11 is rotationally connected, the other end of the sprocket 10 is provided with a central gear, the central gear is connected to the planetary gear system, the other end of the planetary gear system opposite to the sprocket 10 is connected to the clutch cover 5, and the other end of the clutch cover 5 is provided with a clutch shaft 4 The end of the clutch shaft 4 away from the clutch cover 5 is provided with a rotating shaft 2, the rotating shaft 2 passes through the head seat 1 from the inner cavity, the clutch cover 5 and the clutch shaft 4, and the clutch shaft 4 and the rotating shaft There are some gaps between 2, and roller 3 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com