A high damping thermal deformation releasing device

A release device and thermal deformation technology, applied in the direction of elastic shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems of large displacement and high structural stress of flexible structural parts, and achieve reduced relative displacement, stable mechanical properties, Effect of High Damping Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

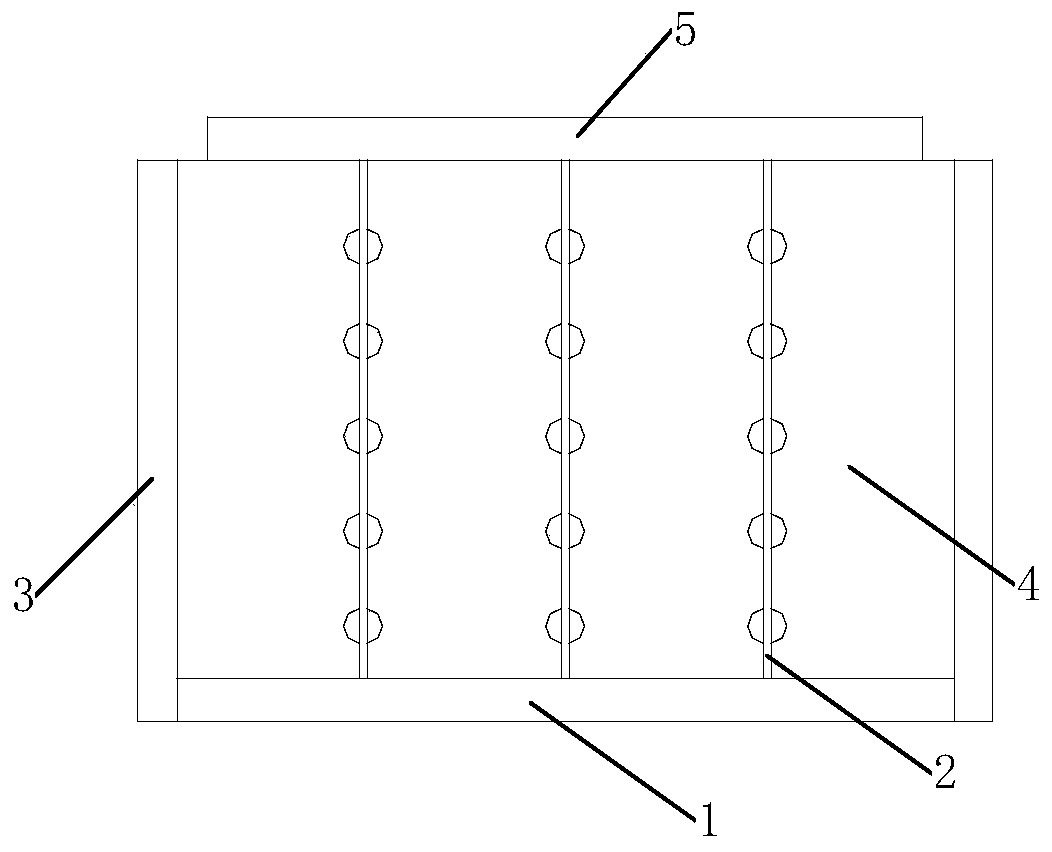

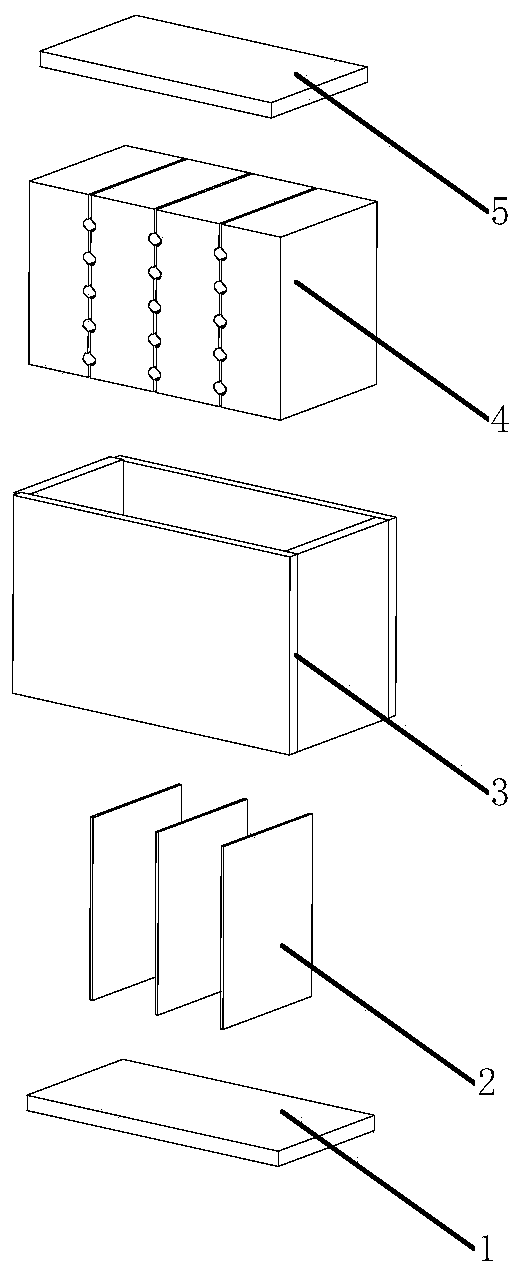

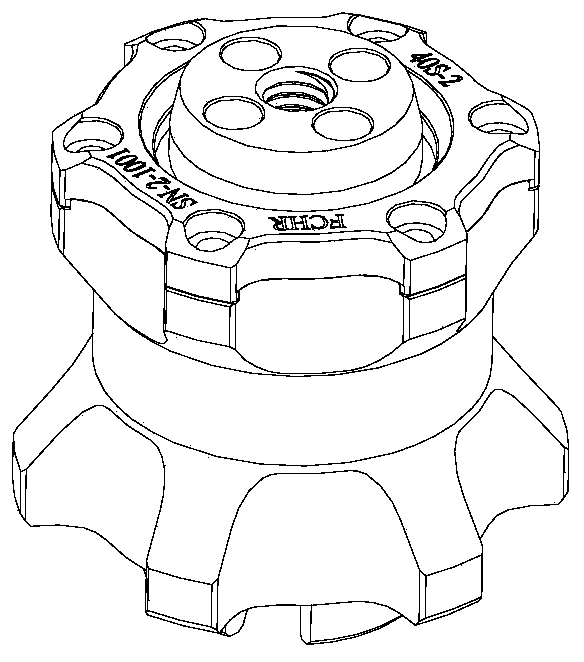

[0025] Combine below Figure 1-Figure 4 The device provided by the present invention is described in detail. The high-damping thermal deformation release device of the present invention includes a base 1 , an elastic element 2 , a shell 3 , a damping element 4 , and a connecting seat 5 . Wherein, the base 1 and the connecting seat 5 are flat plates made of metal. The lower end of the elastic element 2 is fixed to the base 1, the elastic element 2 is perpendicular to the base 1, the upper end of the elastic element 2 is fixed to the connecting seat 5, and the elastic element 2 is vertical to the base 1. The stiffness in the direction of the base 1 is greater than the stiffness of the elastic element 2 in a direction parallel to the base 1, the shell 3 is connected to the base 1, and the elastic element 2 is enclosed inside the shell 3; the damping element 4. Filling between the elastic element 2 and the housing 3, there is a gap on the contact surface between the damping eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com