Graded cross-linked compression sensing supercapacitor and preparation method thereof

A supercapacitor and compressive sensing technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, instruments, etc., can solve the problems that the array of aligned carbon nanotubes cannot bear stress and strain reversibly, and has no compressibility, etc. , to achieve excellent energy storage and strain sensing performance, good capacitance change response, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

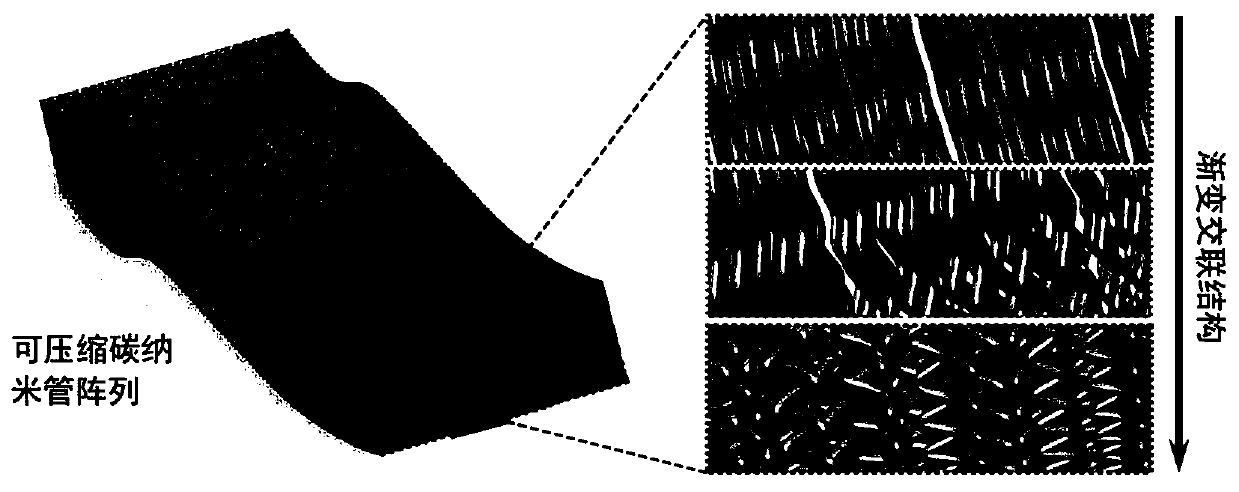

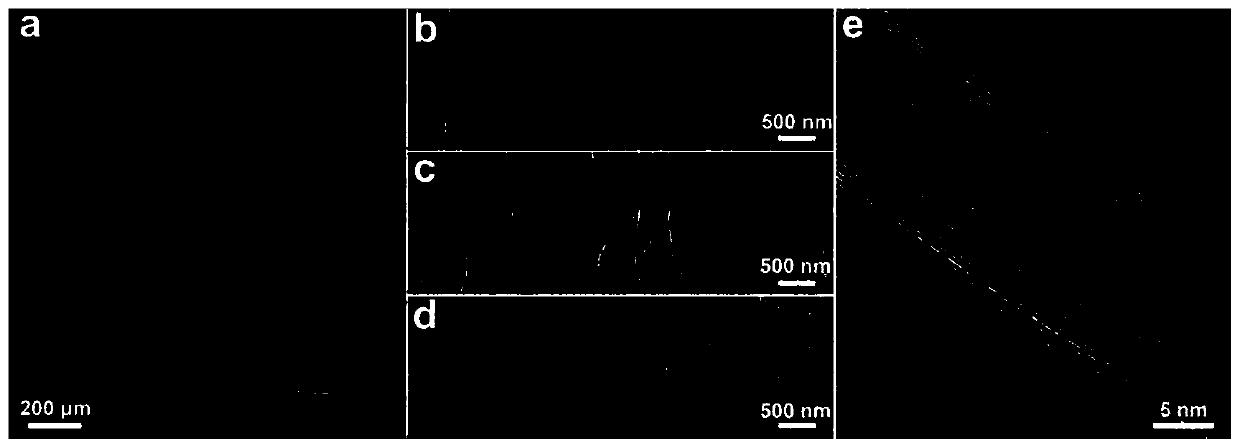

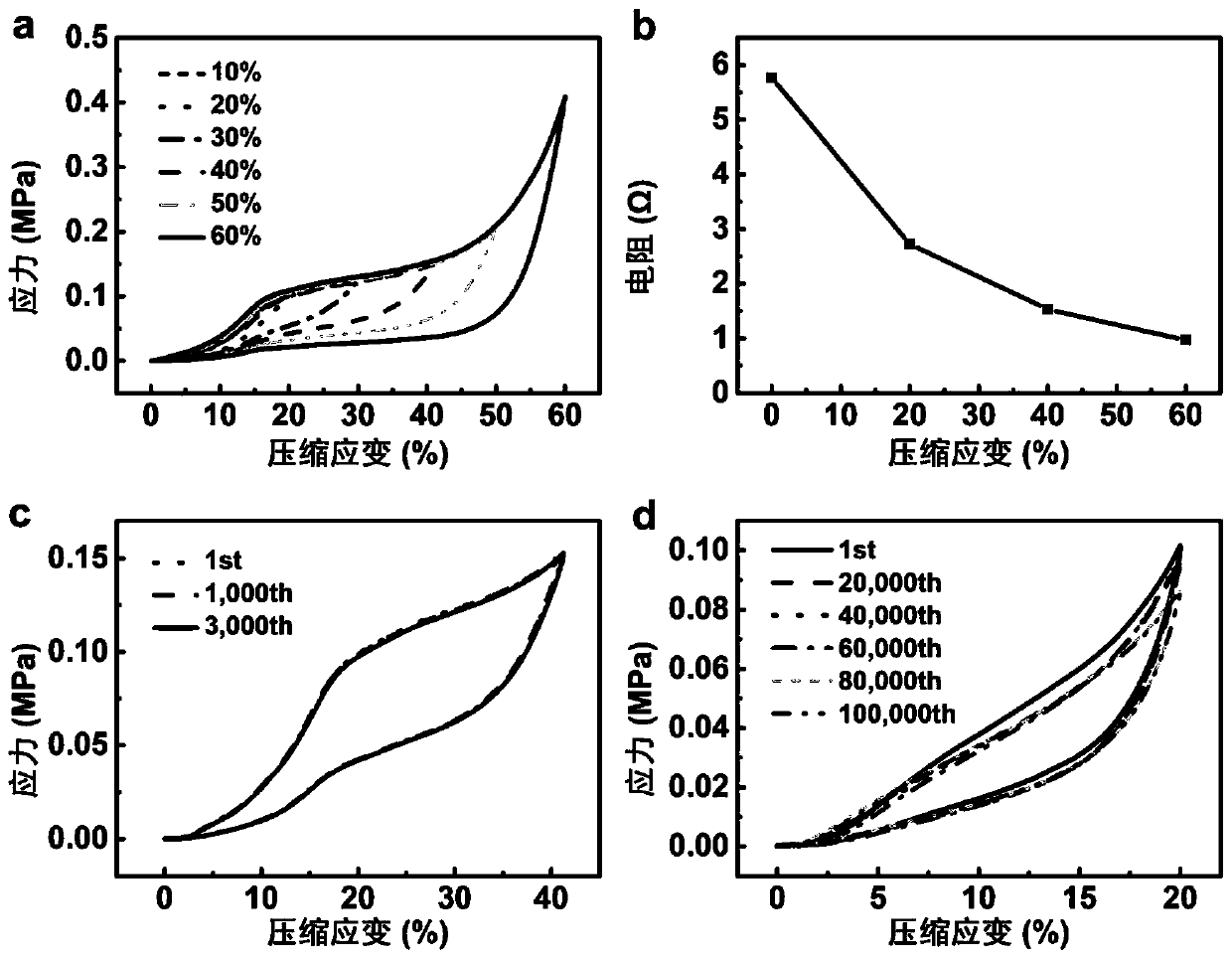

[0026] (1) Preparation of compressible carbon nanotube array electrode with gradient crosslinking structure

[0027] The gradient cross-linked compressible carbon nanotube array electrode is prepared by chemical vapor deposition, and the method is as follows: firstly, a catalyst is deposited on a silicon wafer by an electron beam evaporation coating apparatus. where Al 2 o 3 The thickness of Fe is 5 nm, the thickness of Fe is 1.2 nm, and the deposition rates of the two are 2 Å / s and 0.5 Å / s, respectively. Using argon and hydrogen as the carrier gas and ethylene as the carbon source, put the catalyst-coated silicon wafer into the tube furnace. After setting the deposition program, cover the lid and start the heating program to grow the carbon nanotube array. The argon gas flow rate is 400 sccm, the hydrogen gas flow rate is 30 sccm, and the ethylene gas flow rate is 90 sccm. The reaction temperature is 750° C., the heating rate is 40° C. / min, and the growth time is 80 minute...

Embodiment 2

[0033] (1) Preparation of compressible carbon nanotube array electrode with gradient crosslinking structure

[0034] The gradient cross-linked compressible carbon nanotube array electrode is prepared by chemical vapor deposition, and the method is as follows: firstly, a catalyst is deposited on a silicon wafer by an electron beam evaporation coating apparatus. where Al 2 o 3 The thickness of Fe is 6 nm, the thickness of Fe is 1.1 nm, and the deposition rates of the two are 2.5 Å / s and 0.6 Å / s, respectively. Using argon and hydrogen as the carrier gas and ethylene as the carbon source, put the catalyst-coated silicon wafer into the tube furnace. After setting the deposition program, cover the lid and start the heating program to grow the carbon nanotube array. The argon gas flow rate is 400 sccm, the hydrogen gas flow rate is 30 sccm, and the ethylene gas flow rate is 90 sccm. The reaction temperature is 750° C., the heating rate is 50° C. / min, and the growth time is 90 minu...

Embodiment 3

[0040] (1) Preparation of compressible carbon nanotube array electrode with gradient crosslinking structure

[0041] The gradient cross-linked compressible carbon nanotube array electrode is prepared by chemical vapor deposition, and the method is as follows: firstly, a catalyst is deposited on a silicon wafer by an electron beam evaporation coating apparatus. where Al 2 o 3 The thickness of Fe is 5 nm, the thickness of Fe is 1.1 nm, and the deposition rates of the two are 2Å / s and 0.4Å / s, respectively. Using argon and hydrogen as the carrier gas and ethylene as the carbon source, put the catalyst-coated silicon wafer into the tube furnace. After setting the deposition program, cover the lid and start the heating program to grow the carbon nanotube array. The argon gas flow rate is 400 sccm, the hydrogen gas flow rate is 30 sccm, and the ethylene gas flow rate is 90 sccm. The reaction temperature is 750° C., the heating rate is 45° C. / min, and the growth time is 100 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com