filter element with removal element

A filter element and buffer element technology, which is applied in the direction of filtration separation, membrane filter, fixed filter element filter, etc., can solve problems such as disconnection and filter body damage, achieve low cost and overcome adhesion friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

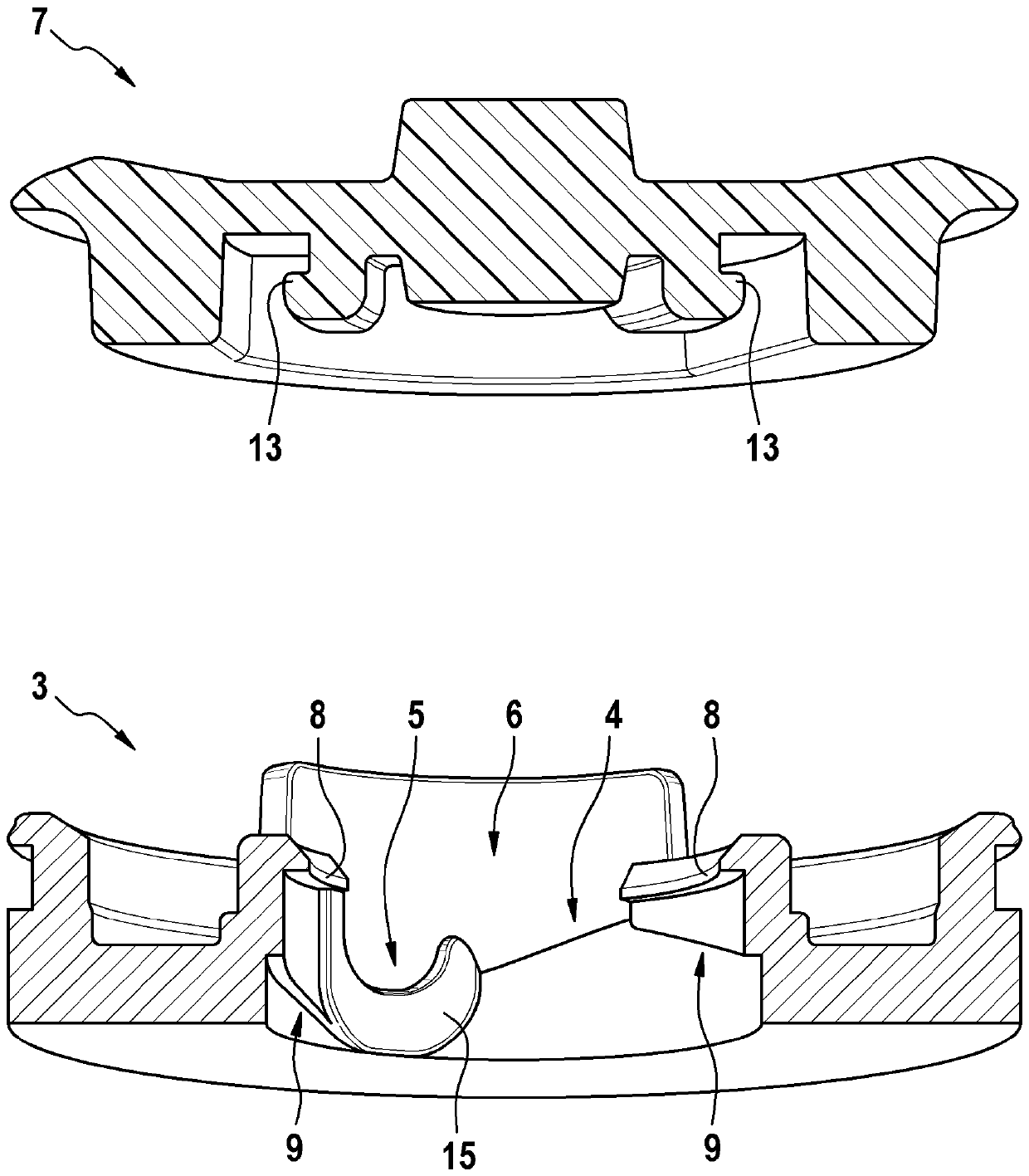

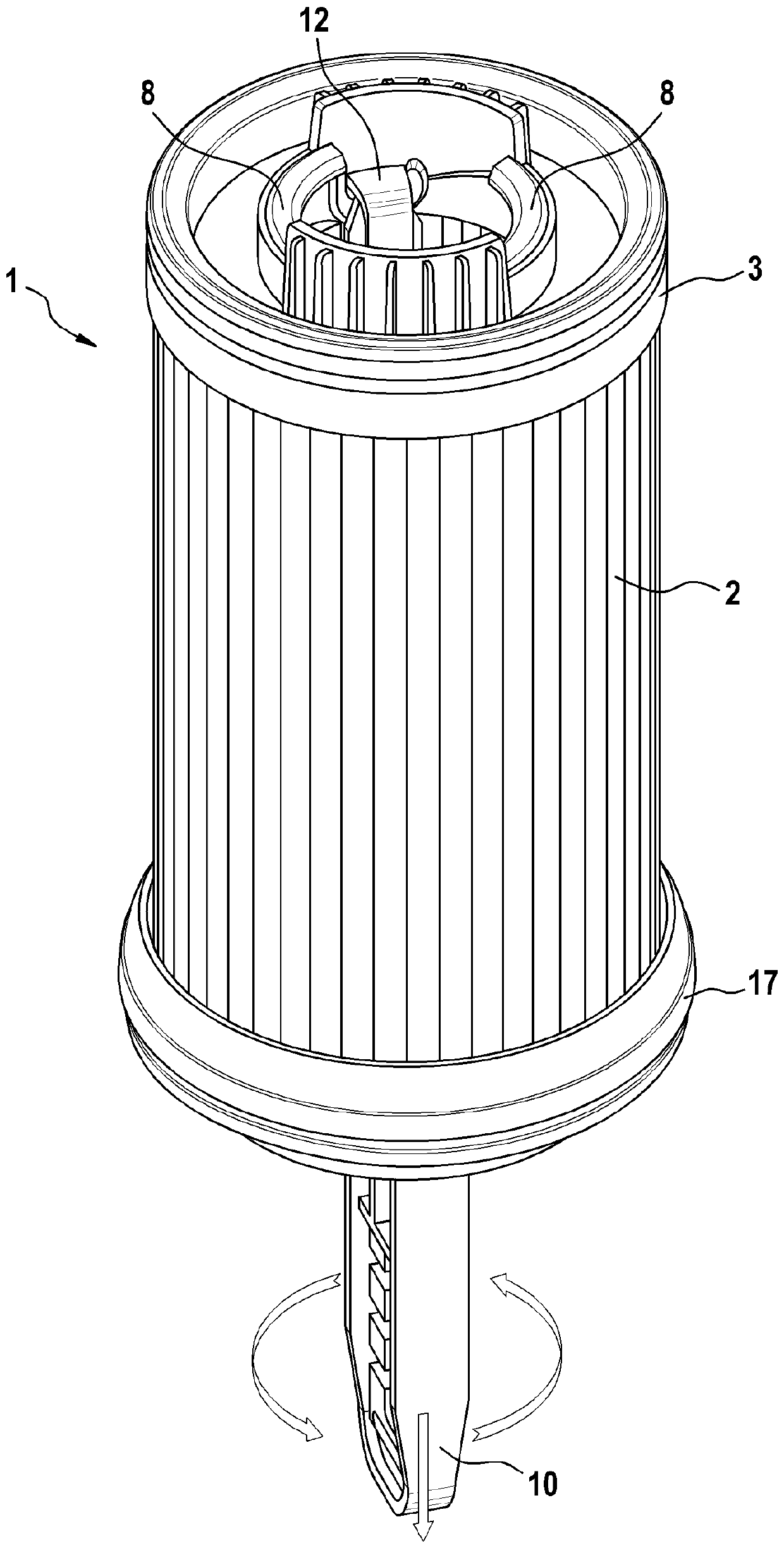

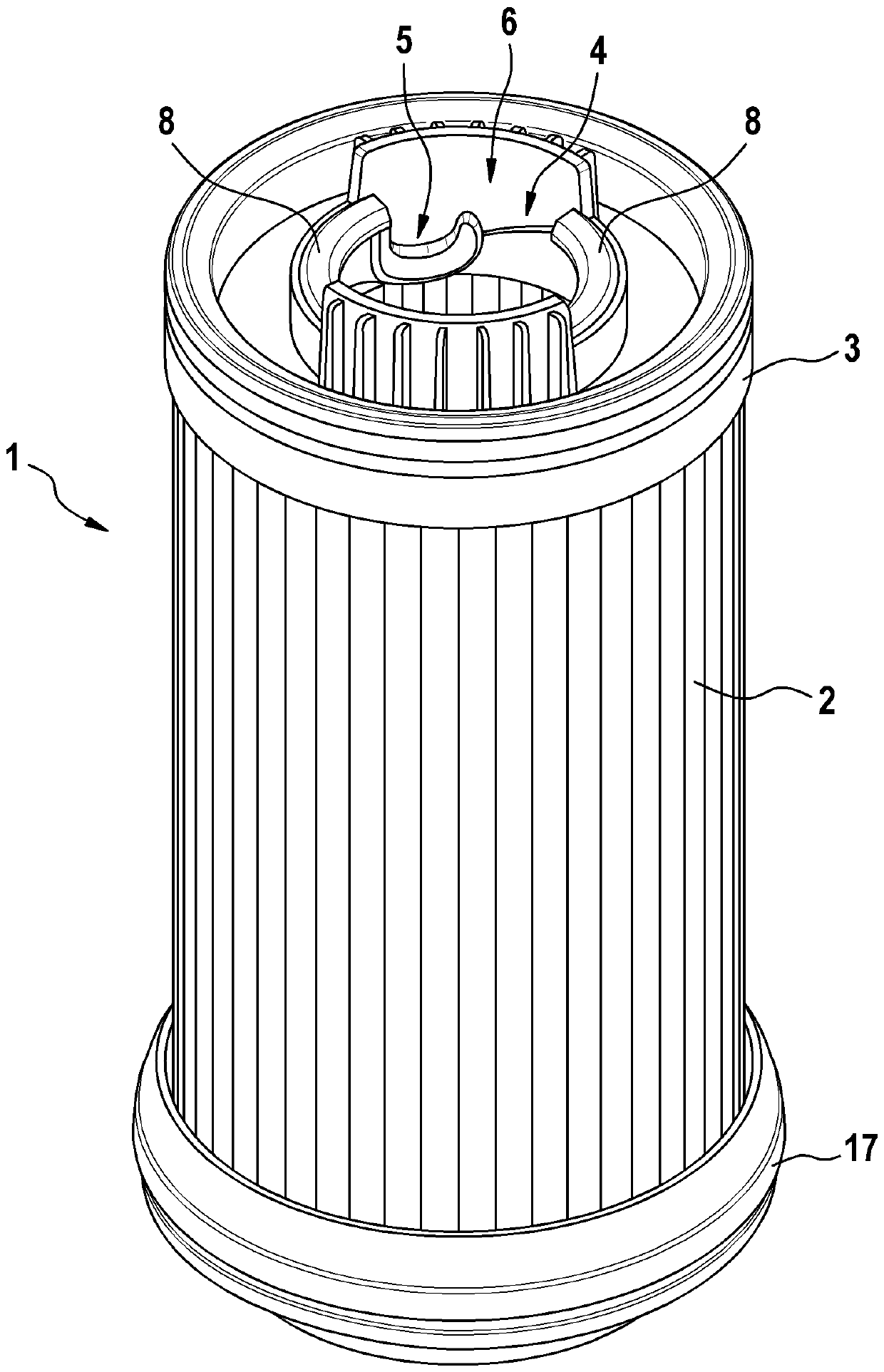

[0025] figure 1 A filter element 1 according to an exemplary embodiment of the invention is shown. The filter element 1 comprises a filter body 2 and an annular closure cap 3 . The closure cap 3 is arranged at the axial end of the filter body 2 , wherein the filter body 2 has a hollow-cylindrical shape, which is designed here as a cylinder. Accordingly, all directional statements regarding the hollow cylinder are indicated below.

[0026] Furthermore, the filter element 1 has an additional second closure cap 17 which is arranged axially on the end of the filter body 2 opposite the closure cap 3 . The additional second closure cap 17 is not considered further within the scope of the present invention. In particular, it is only provided that the additional second closure bell 17 is annular and has an inner diameter which at least corresponds to the largest inner diameter of the closure bell 3 . In the exemplary embodiment shown, the filter element 1 has no support tube in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com