Rotary eccentric casing pipe internally drilling device

A drilling device and eccentric technology, which can be applied in the drilling driving device, drilling equipment and method, drilling equipment, etc. The effect of increasing the scale, reducing the requirements, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

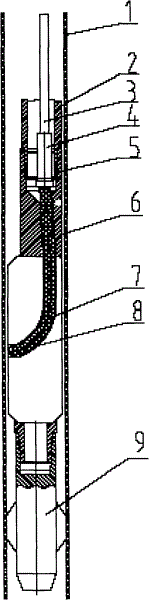

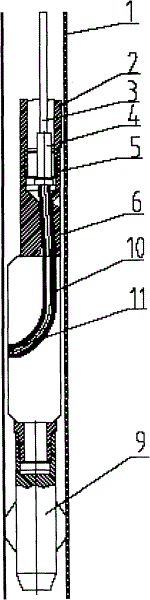

[0012] The following is attached with the manual figure 1 . figure 2 The present invention is further described.

[0013] exist figure 1 Among them, the coiled tubing 3 , the rotary drive mechanism 4 , the upper joint 5 , the flexible shaft 7 and the milling bit 8 are connected together, and the eccentric steering mechanism 6 is connected with the anchor 9 . The flexible shaft 7 and the milling bit 8 are in the cavity of the eccentric steering mechanism 6, and the entire drilling tool structure is anchored on the inner wall of the casing 1 through the anchor 9.

[0014] exist figure 2 Among them, the coiled tubing 3 , the rotary drive mechanism 4 , the upper joint 5 , the hose 10 and the rotary jet drill bit 11 are connected together, and the eccentric steering mechanism 6 is connected with the anchor 9 . The hose 10 and the rotary drilling bit 11 are in the cavity of the rotary driving mechanism 6 , and the entire drilling tool structure is anchored on the inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com