Zero-tension taping machine main shaft structure

A tape wrapping machine, zero tension technology, applied in the direction of electrical components, circuits, cable/conductor manufacturing, etc., to ensure stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

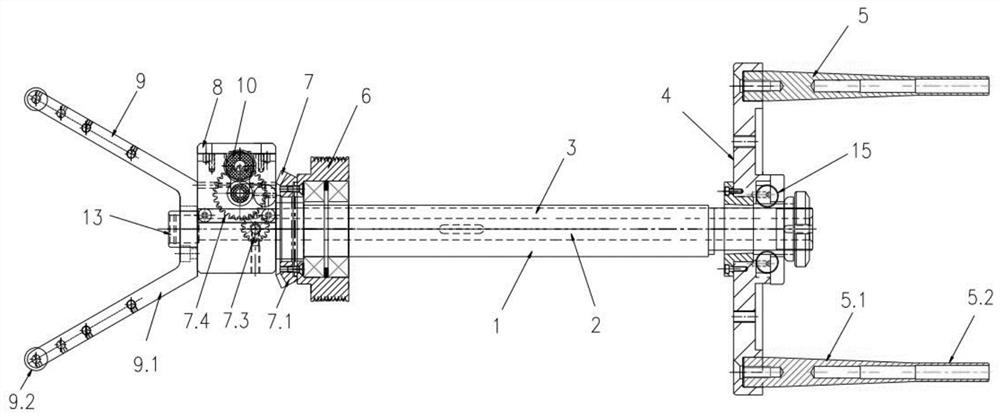

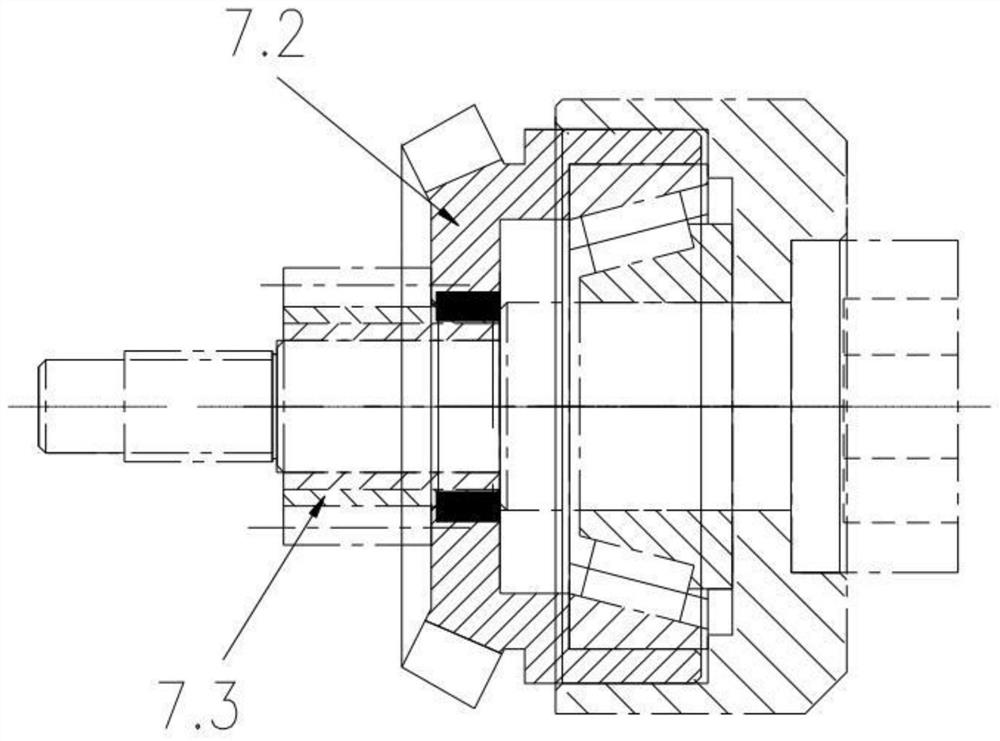

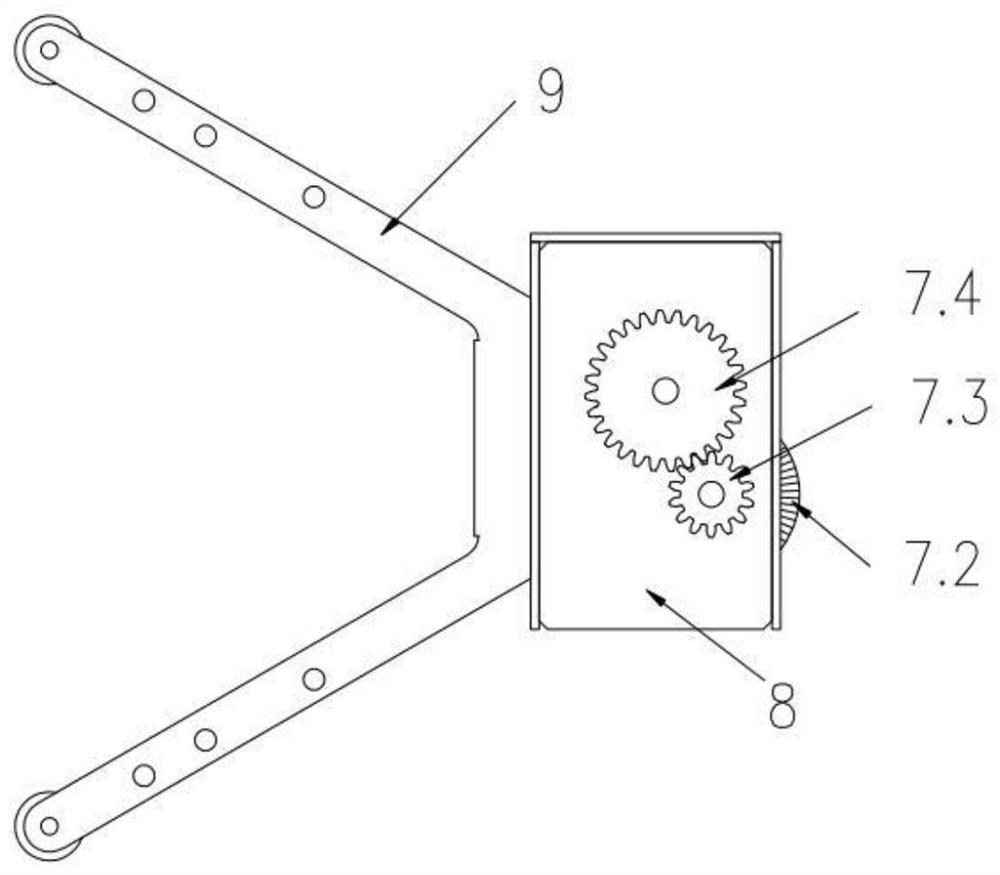

[0019] combined with figure 1 , a main shaft structure of a zero-tension taping machine, comprising a main shaft 1, a central rod 2 arranged in the center of the main shaft 1, and a wire slot 3 arranged on one side of the central rod 2, and the outer end of the main shaft 1 is provided with a lead wire structure , the other end is provided with an outlet structure, the lead structure includes a disc body 4 arranged at the end of the main shaft 1, the side of the disc body 4 away from the main shaft 1 is provided with several wire passing rods 5 along the circumference, the outlet structure Sleeved on the other end of the main shaft 1 and flexibly connected with the main shaft 1, the outlet structure includes a multi-groove pulley 6, a bevel tooth assembly 7, a head assembly 8, and a horn assembly 9 arranged in sequence from the lead end to the outlet end. The multi-groove pulley 6 is movably arranged on the main shaft 1 through bearings, and is driven by an independent motor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com