Water level control valve with flow rate continuous control function

A technology of water level control and flow, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problem of inability to accurately control the water output of the valve, achieve less instability, sensitive valve action, and overcome the friction of the valve core Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

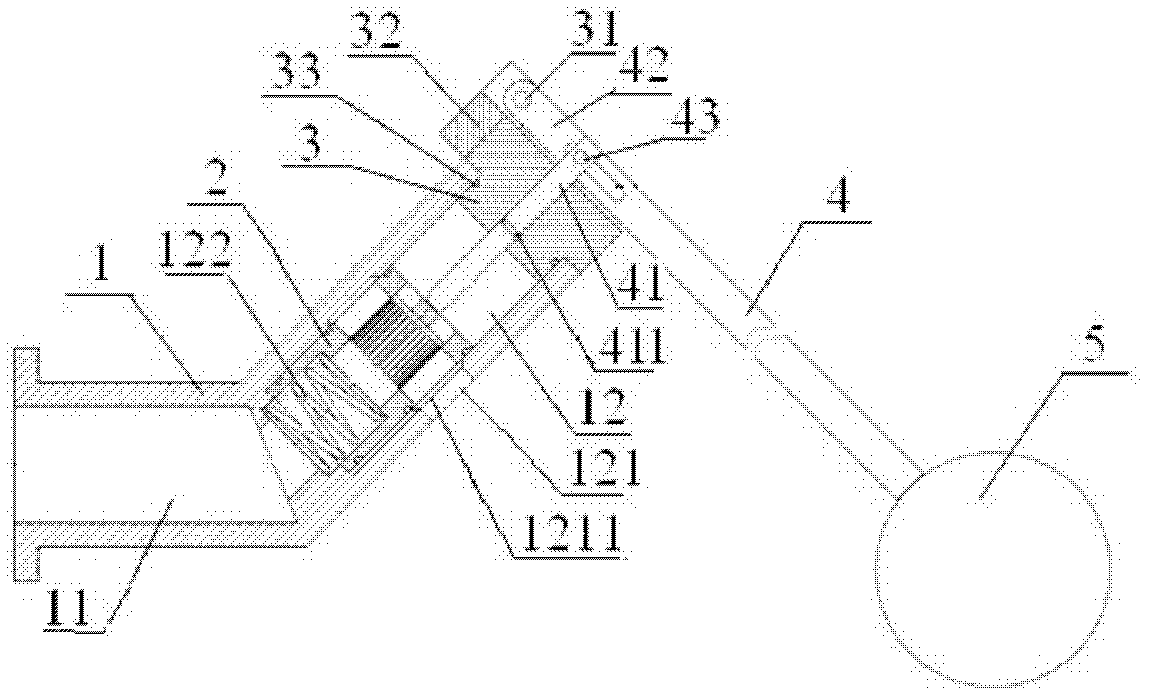

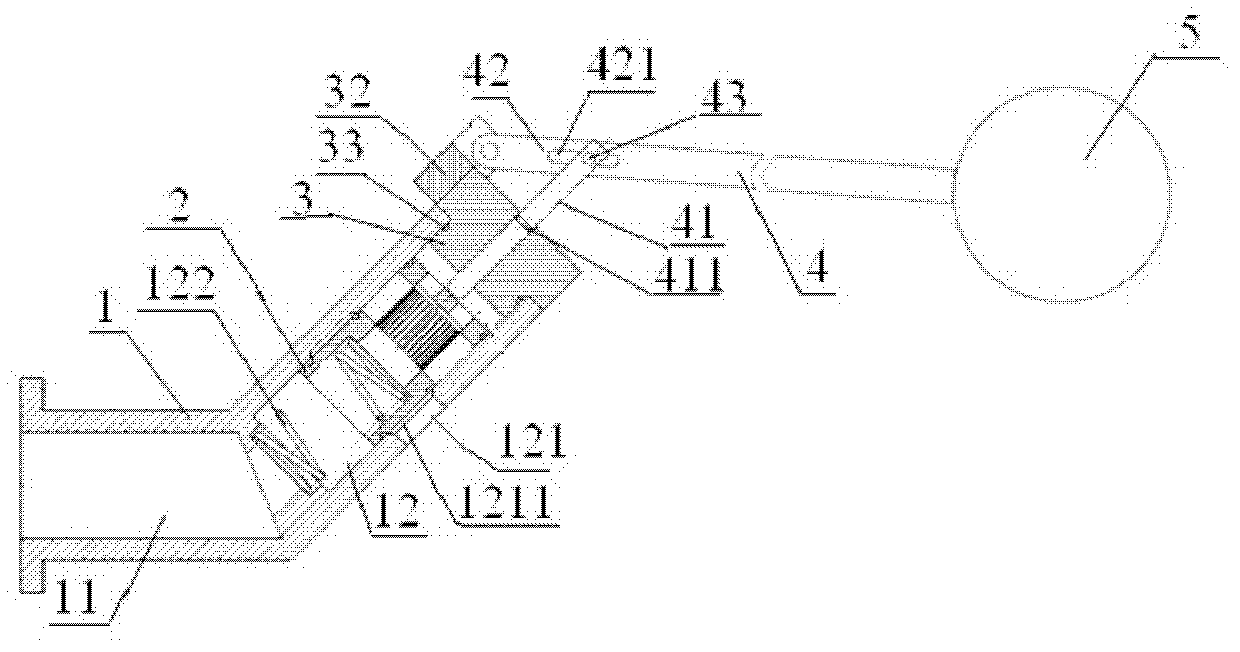

[0019] Further illustrate the present invention below in conjunction with accompanying drawing

[0020] Referring to the attached picture:

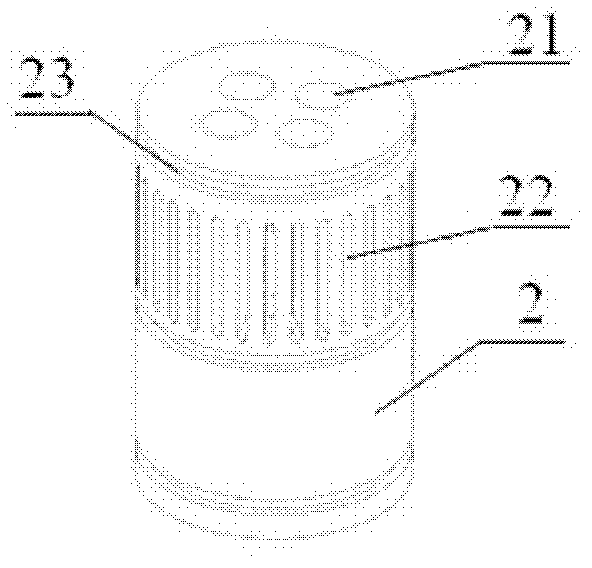

[0021] The water level control valve with continuous flow control function according to the present invention includes a valve body 1, a valve core 2, a valve body cover 3, a float connection device 4, and a float 5, and the valve body 1 is provided with a water inlet chamber 11 . The water outlet chamber 12, the side wall of the water outlet chamber 12 is provided with a water outlet hole 121, and a return spring 122 is installed inside the end connected to the water inlet chamber 11, the valve core 2 is placed inside the water inlet chamber 11, The end of the return spring 122 is inserted into the water inlet end of the spool 2; the water inlet end of the spool 2 is provided with a step hole 21 cooperating with the return spring, and a balance hole 22 is provided on the water outlet end; the valve The body cover 3 is provided with a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com