Tool coupling arrangement for drills and reamers

A coupling device and tool technology, applied in reamers, manufacturing tools, drilling tool accessories, etc., can solve the problems of not being able to reinforce the tapered seat and affecting discarding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the following description, various aspects of the subject matter of the present application will be described. For the purpose of illustration, specific configurations and details are explained in sufficient detail to provide a thorough understanding of the subject matter of this application. However, it is obvious to those skilled in the art that the subject matter of the present application can be implemented without the specific configuration and details given herein.

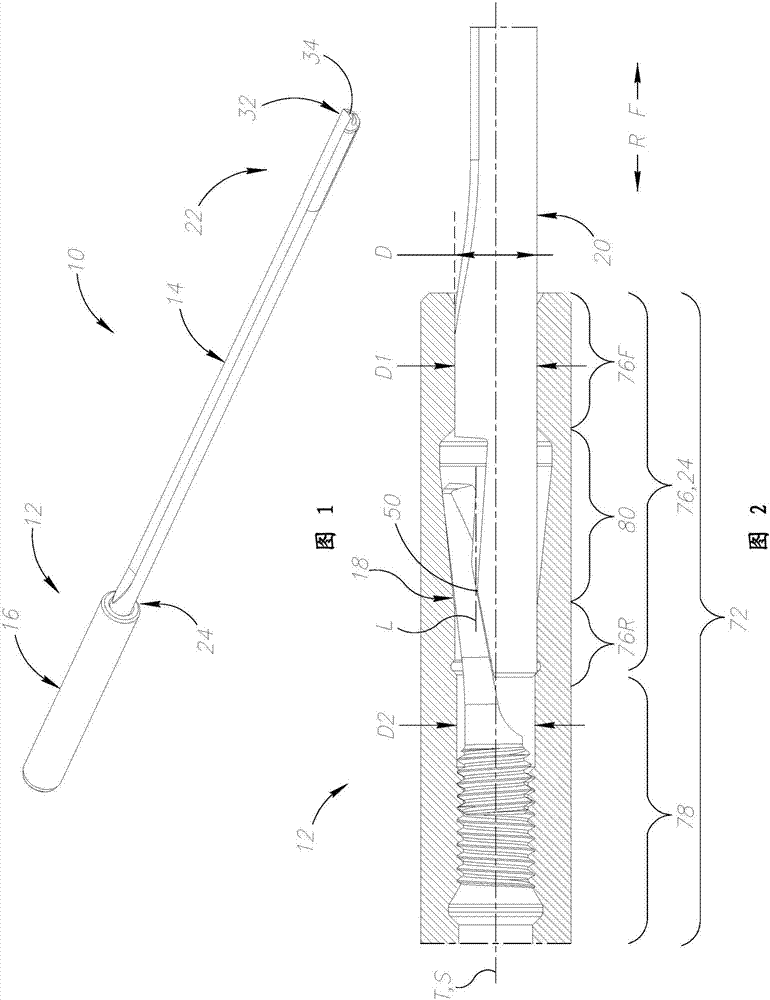

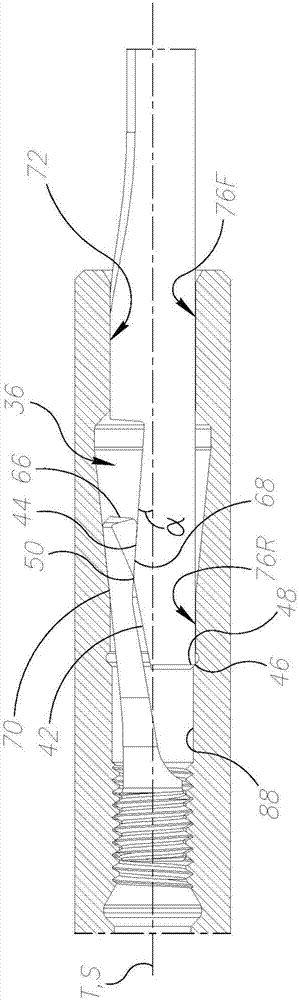

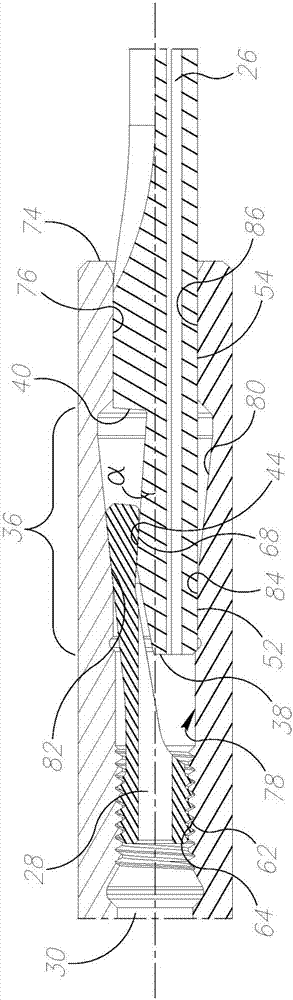

[0031] Reference figure 1 with figure 2 . The drill bit 10 has a coupling device 12, which includes a tool portion 14 and a shank portion 16, which are coupled together by an internal, elongated coupling member 18. The assembled drill bit 10 defines the front to back direction (F, R), which is figure 2 Defined by arrows. To assemble the drill bit 10, the tool part 14 is axially inserted into the shank part 16 until the coupling device 12 reaches the assembly position. Then, the tool part 14 is ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com