Method for producing microbiologic agent, and microbiologic agent

一种微生物制剂、微生物的技术,应用在生物化学设备和方法、微生物的测定/检验、化学仪器和方法等方向,能够解决制造成本高、分解微生物很长时间、驯化需要很长时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

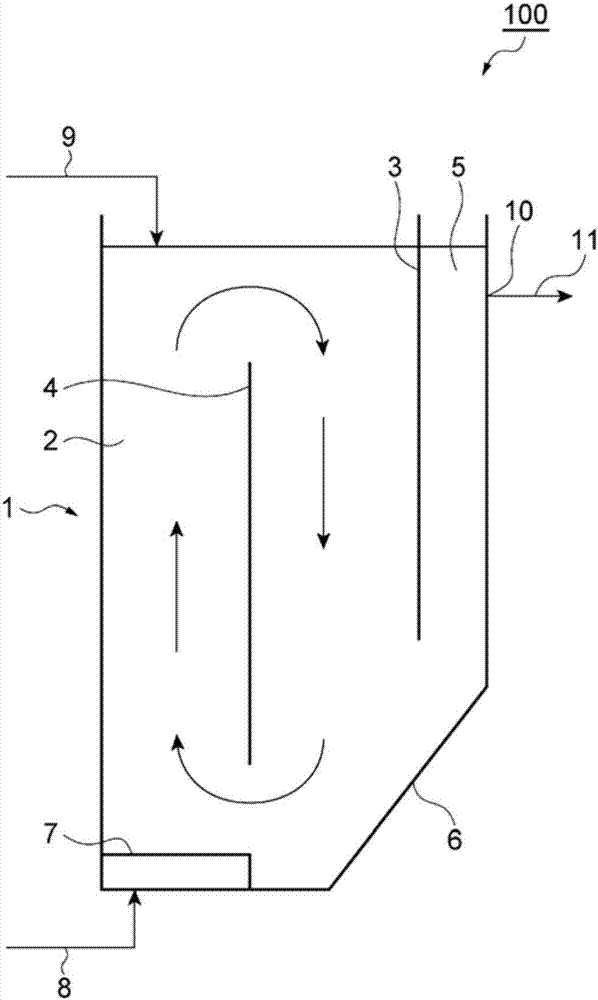

Method used

Image

Examples

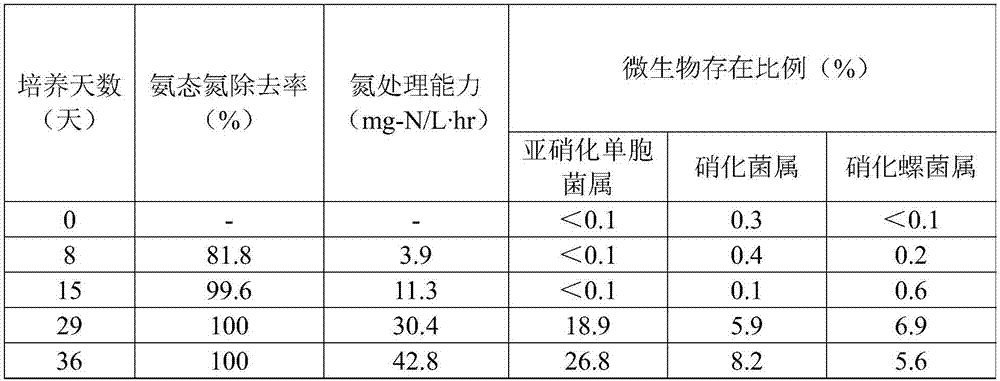

Embodiment 1

[0074] (Material)

[0075] Concentrates of the components used in the production of the culture medium were prepared by the method shown below. Will (NH 4 ) 2 SO 4 35.4g and Na 2 HPO 4 7.7g was dissolved in 500mL of pure water to make a nitrogen and phosphorus solution with ammoniacal nitrogen of 15000mg / L. KCl 110g and CaCl 2 2H 2 O 50g and CoCl 2 1 mg was dissolved in 1000 mL of pure water to prepare inorganic salt solution 1. NaMoO 4 2H 2 O 5 mg was dissolved in 1000 mL of pure water to prepare inorganic salt solution 2. MgSO 4 ·7H 2 O 85g, FeSO 4 ·7H 2 O8.5g, MnSO 4 ·5H 2 O 2g, ZnSO 4 100mg and CuSO 4 ·5H 2 100 mg of O was dissolved in 1000 mL of pure water to prepare inorganic salt solution 3. The medium in the supply culture was produced as follows: (NH 4 ) 2 SO 4 0.2g and Na 2 HPO 4 1.54 g was dissolved in 1000 mL of pure water, and 1 ml of inorganic salt solution 1, 1 ml of inorganic salt solution 2, and 1 ml of inorganic salt solution 3...

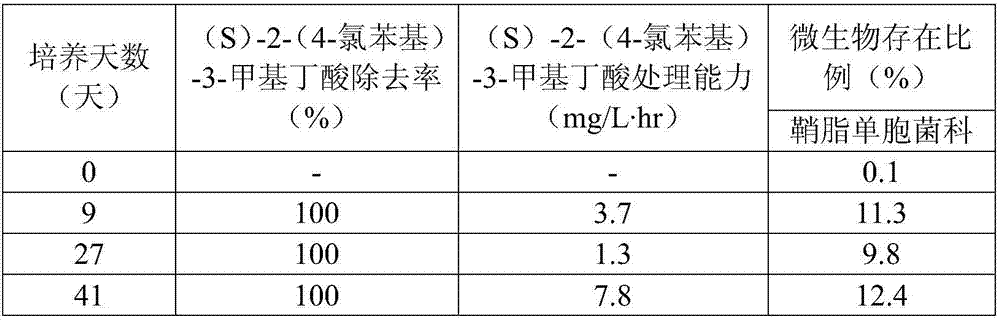

Embodiment 2

[0107] (Material)

[0108] Concentrates of the components used in the production of the culture medium were prepared by the method shown below. MgSO 4 ·7H 2 O100g was dissolved in 1000mL of pure water to make inorganic salt solution A. Na 2 HPO 4 4.152g, NaH 2 PO 4 2.244g and (NH 4 ) 2 SO 4 1.2 g was dissolved in 300 mL of pure water to prepare inorganic salt solution B. (S)-2-(4-chloro Phenyl)-3-methylbutyric acid solution (10g / L). The inorganic particle carrier dispersion was produced by adding 50 g of activated sludge incineration ash to 250 ml of pure water, mixing and suspending. As the activated sludge suspension, the activated sludge collected from the aeration tank of the chemical factory is directly used. The medium that is supplied to the culture is produced as follows: (NH 4 ) 2 SO 4 1.0g, Na 2 HPO 4 1.3g and NaH 2 PO 4 Dissolve 0.9g in 1000mL of pure water, add (S)-2-(4-chlorophenyl)-3-methylbutyric acid solution 4.0mL and 1ml inorganic sa...

Embodiment 3

[0136] The inorganic salt solution used in the production of the culture medium was the same as in Example 1, and the inorganic salt solution 1, the inorganic salt solution 2, and the inorganic salt solution 3 were prepared. (S)-2-(4-Chlorophenyl)-3-methylbutanoic acid solution used the same solution as in Example 2. The influent water was prepared as follows: (S)-2-(4-chlorophenyl)-3-methylbutyric acid solution 1mL, (NH4) 2 SO 4 1g, Na 2 HPO 4 1.298g, NaH 2 PO 4 0.912 g was dissolved in 1000 mL of pure water, and 1 ml of inorganic salt solution 1, 1 ml of inorganic salt solution 2, and 1 ml of inorganic salt solution 3 were added to manufacture. Since the influent water is continuously supplied during the (S)-2-(4-chlorophenyl)-3-methylbutanoic acid removal reaction period, the required amount is appropriately produced. The activated sludge suspension was directly used from the activated sludge collected from the aeration tank of the chemical factory.

[0137] ((S)-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com