Production method of paraffin

A production method and paraffin technology, applied in organic chemical methods, chemical instruments and methods, hydrogenation hydrocarbon production, etc., can solve problems such as incapable of stable and efficient production, uneven generation of impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

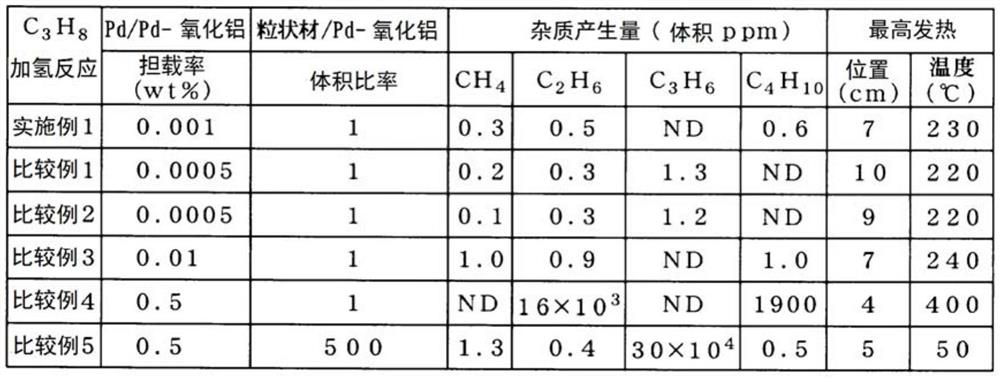

[0042] Propane was produced by the hydrogenation reaction of propylene using the paraffin production apparatus 1 of the above-described embodiment.

[0043] The reaction tower 10 was made of stainless steel and had an inner diameter of 31 mm. The filling height of the granular member in the reaction tower 10 was set to 50 cm. All the granular parts packed in the reaction tower 10 were used as a catalyst-carrying carrier. That is, the ratio of the sum of the volume of the entire carrier on which the catalyst is supported and the volume of all the granular members not carrying the catalyst relative to the volume of the entire carrier on which the catalyst is supported is 1 time. As the carrier supporting the catalyst, a product of NE Kaijia Co., Ltd. with an average particle diameter of 3 mm was used. Each carrier of this example was made of alpha alumina, and supported palladium (Pd) as a catalyst. The ratio of the weight of the catalyst carried on each carrier to the sum of...

Embodiment 2

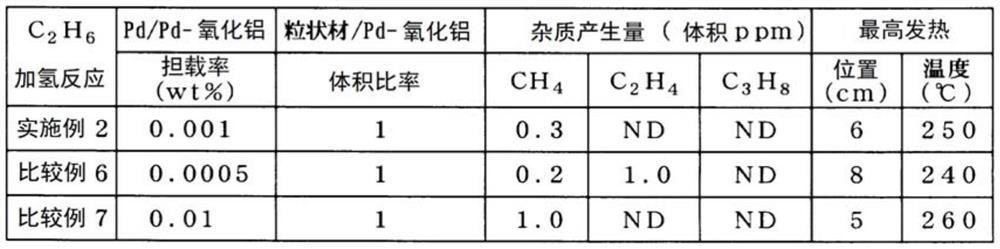

[0071] Ethane was produced by hydrogenation of ethylene under the same conditions as in Example 1, except that ethylene having a purity of more than 99.99% by volume was supplied from the olefin gas cylinder 2 .

[0072] By the hydrogenation reaction of ethylene in the reaction tower 10 under the above conditions, the maximum exothermic temperature was 250°C at a position 6 cm away from the inlet 10a in the reaction tower 10 .

[0073] The impurities contained in the ethane gas discharged from the outlet 10b of the reaction tower 10 were analyzed by a gas chromatograph 17 manufactured by Shimadzu Corporation. Among the impurities other than hydrogen, residual ethylene was less than 0.1 vol ppm and methane was 0.3 vol. ppm, propane is less than 0.1 volume ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com