Battery terminal and method for producing a battery terminal

A battery and terminal technology, applied in the direction of conductive connection, electrical connection seat, electrical component connection, etc., can solve the problem of difficult access to spiral devices, and achieve the effects of good accessibility, reduced complexity, and reduced geometric complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

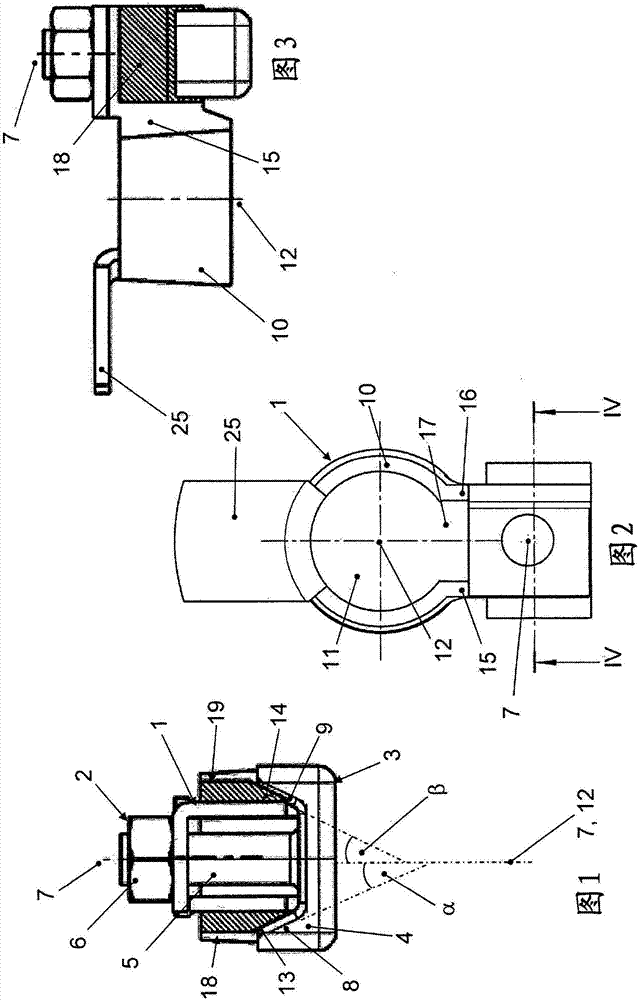

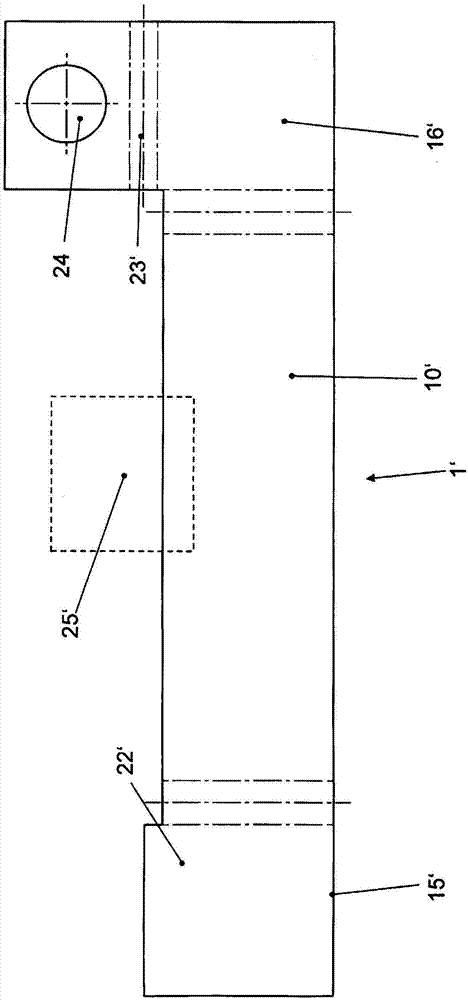

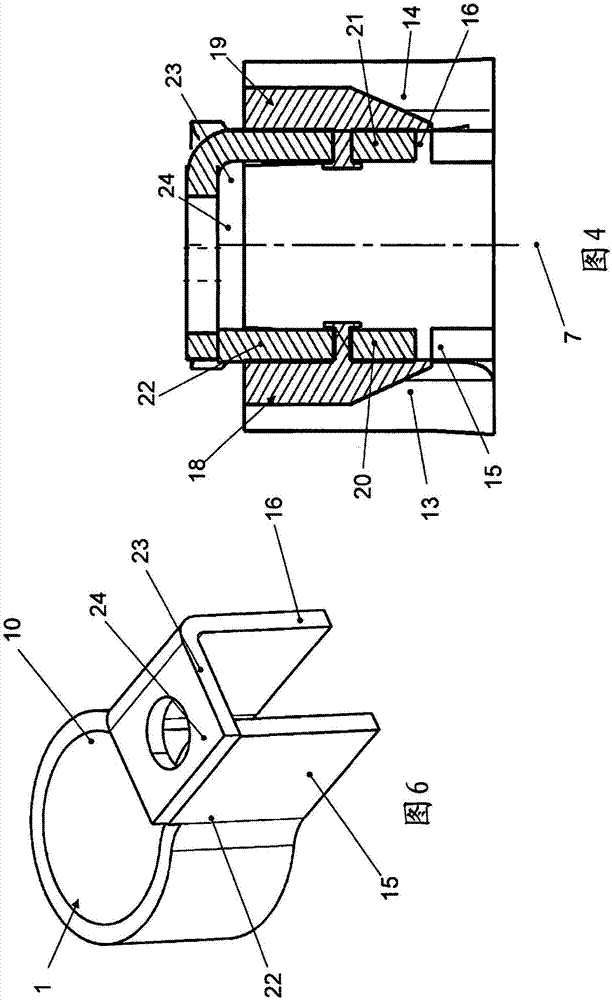

[0023] Identical or functionally identical components are provided with the same reference symbols in the various figures.

[0024] battery terminal Figure 1 to Figure 4 The embodiment shown in includes a one-piece stamped and bent part 1 and a screw element 2 . The screw element 2 comprises a bolt 3 with a head 4 and a threaded section 5 and a nut 6 into which the threaded section 5 can be screwed. The cylinder axis 7 of the threaded section 5 is at figure 1 , figure 2 and image 3 drawn in.

[0025] The stamped and bent part 1 is at least partially produced from an electrically conductive material, in particular a metal, for example copper or a copper alloy.

[0026] On the side of the head 4 facing the threaded section 5, two opposite inclined surfaces 8, 9 are provided, which are aligned with the axial direction of the threaded section 5 or its cylinder. The axis 7 forms an angle α, which in the illustrated embodiment is between 10° and 40°, in particular between 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com