A microvascular stapler

A stapler and microvascular technology, applied in the field of medical devices, can solve the problems of complex structure of vascular stapler, prone to vascular embolism, large residual area, etc., to reduce the risk of vascular embolism, reduce the risk of vascular embolism, and small contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

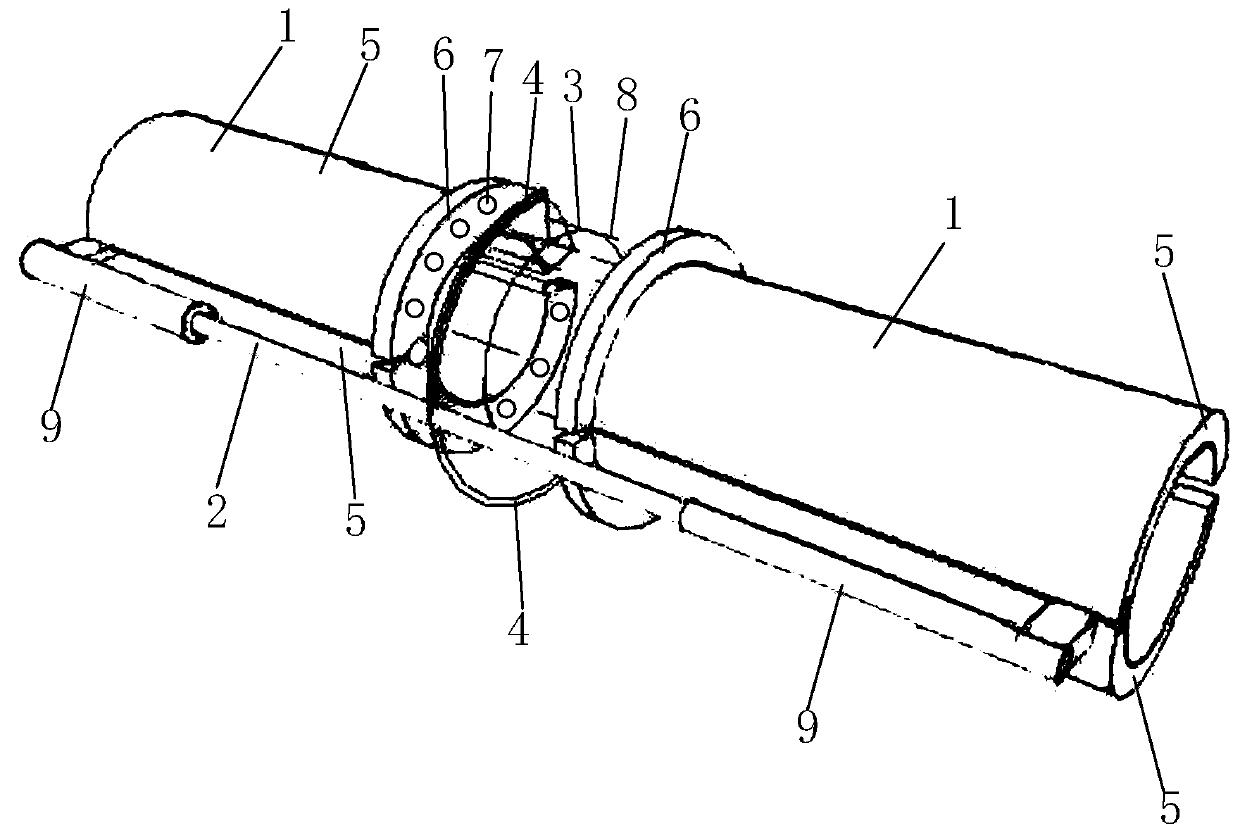

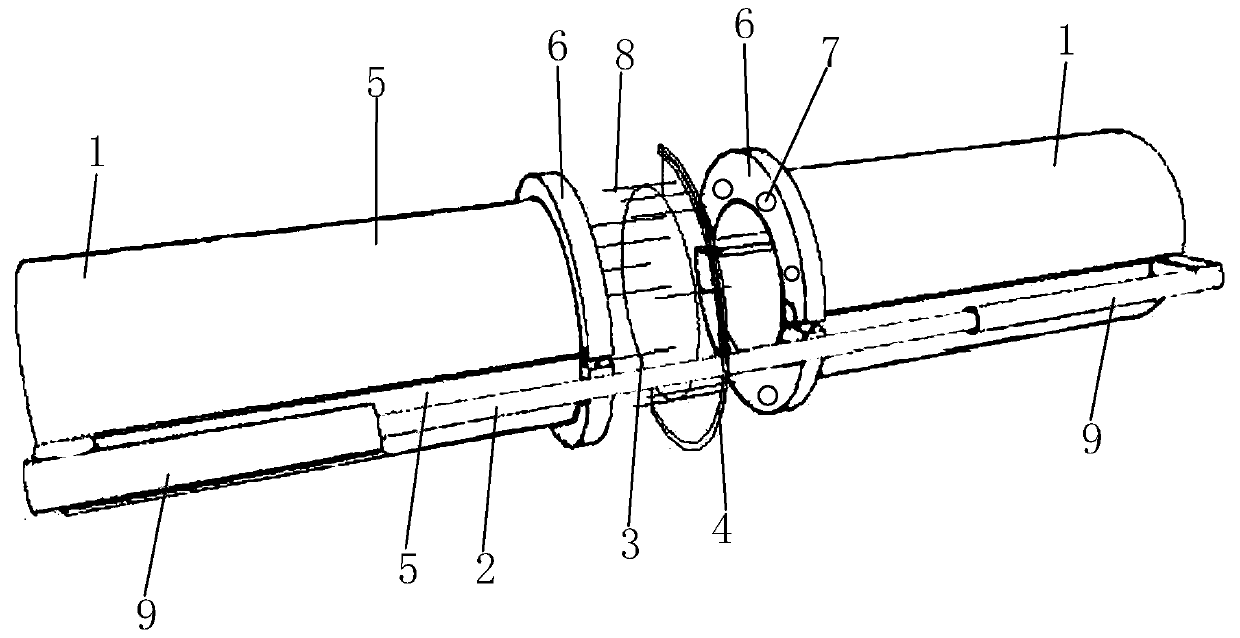

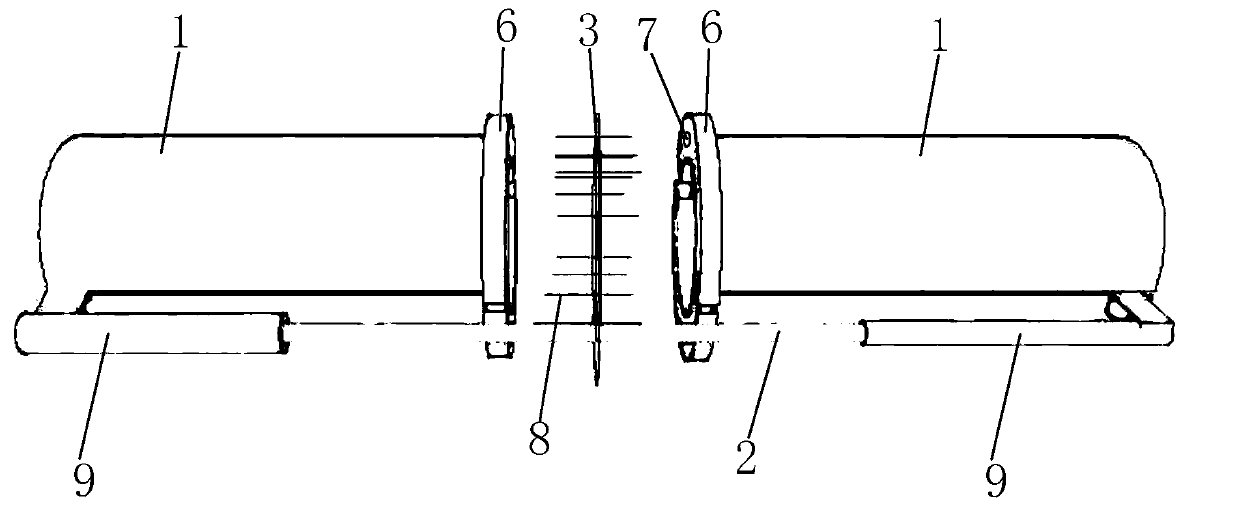

[0023] Embodiment: a kind of microvascular stapler

[0024] The microvascular stapler includes two sleeves 1 with the same diameter, a sliding rod 2, staples 3 and a nail seat 4; the sleeve 1 is a tubular member formed by hinged and joined together of two arc-shaped segments 5, The outer periphery of the mouth of one end of the casing 1 is provided with a flange 6, and the flange 6 is provided with a plurality of negative pressure holes 7 along the mouth of the pipe, and the negative pressure holes 7 are specifically through holes; the slide bar 2 is a rod-shaped member, and the two sleeves 1 are slidably connected to the sliding rod 2 on the outer wall of the tube in a symmetrical manner with the flange 6 facing each other. The specific sliding connection method is that the sleeve 1 is fixed with a sliding sleeve 9 , the sliding sleeve 9 is sleeved on the sliding rod 2, so that the sleeve 1 can slide relative to the sliding rod 2, of course, other sliding connection methods i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com