Spring plate capable of adjusting comfort degree

A technology of spring plate and comfort, which is applied in the field of adjustable comfort spring plate, which can solve the problem that the spring plate cannot adjust the comfort level, and achieve the effect of reducing vibration and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

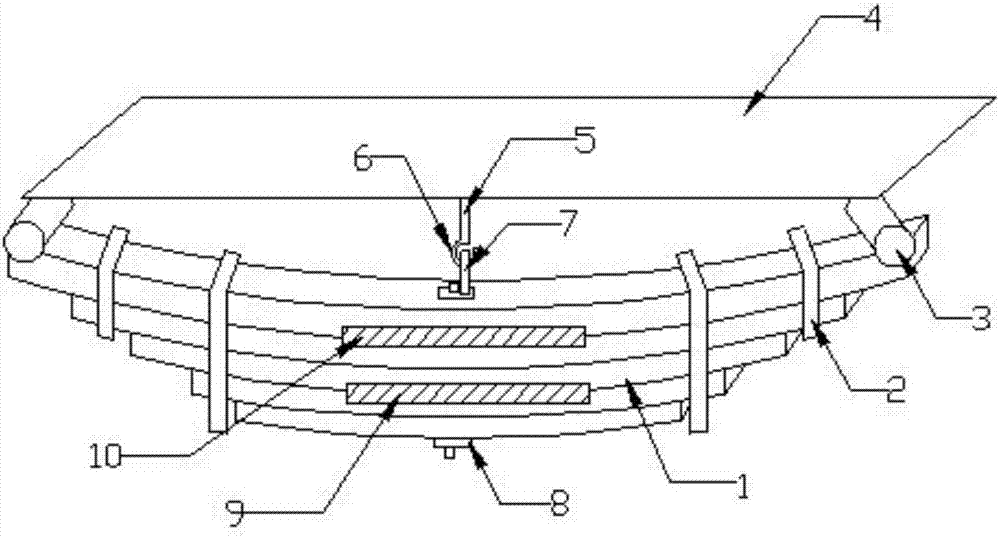

[0017] Such as figure 1 As shown, the comfort-adjustable spring plate of the present invention includes a spring plate body 1, a first fastener 2, a lifting lug 3, a truck floor 4, a telescopic rod 5, a first hook 6, a second hook 7, and a central bolt 8. The first groove 9 and the second groove 10, the outside of the spring plate body 1 is provided with a first fastener 2, the two ends of the spring plate body 1 are provided with lifting lugs 3, and the lifting lugs 3 are connected by connecting pieces The lower surface of the truck bed 4, the inside of the spring plate body 1 is provided with a first groove 9 and a second groove 10, and a rubber layer is installed inside the first groove 9 and the second groove 10, and the spring plate body 1 is provided with a central bolt 8, one side of the central bolt 8 is provided with a second hook 7, and above the second hook 7 is provided with a first hook 6, and the first hook 6 is connected to the truck floor 4 through a telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com