Conveyor system used for goods inlet and outlet at stereoscopic warehouse

A three-dimensional warehouse, incoming and outgoing technology, applied in the field of conveyors, can solve problems such as easy to fall, easy to break down, and goods entering and leaving the warehouse cannot be stopped in time, so as to achieve the effect of easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

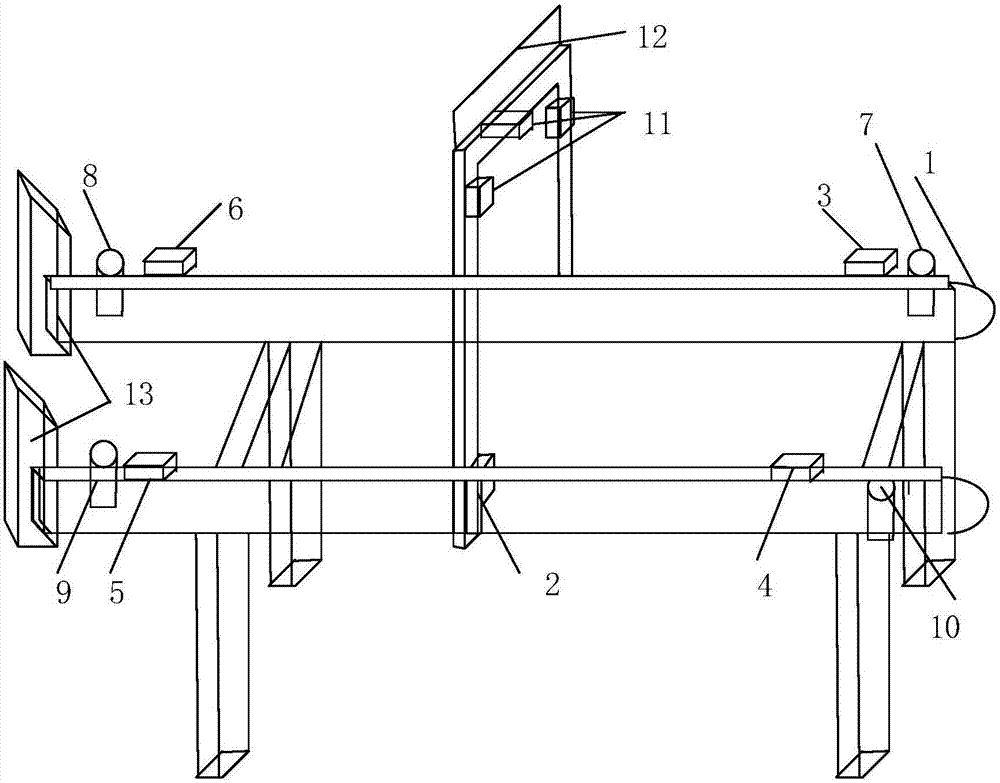

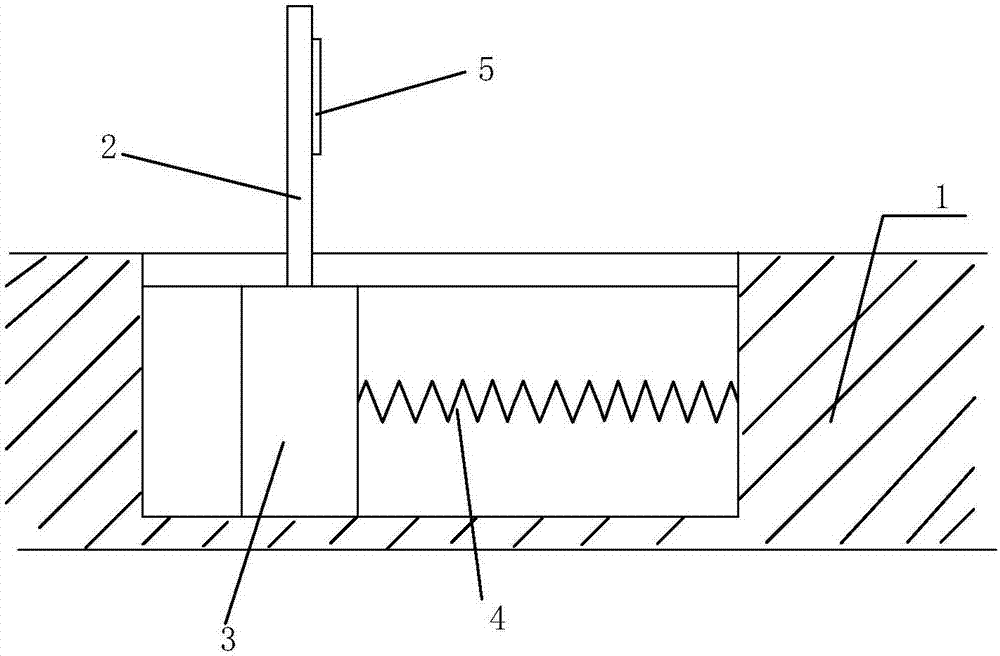

[0020] In order to better understand the present invention, a specific embodiment is provided here, and this embodiment is a kind of delivery conveyor system for intelligent three-dimensional warehouse, such as figure 1 As shown, the conveying track 1 is set on a platform with four supporting legs, and both ends of the conveying track 1 are equipped with a through-beam photoelectric sensor 3-6 and a buffer stop mechanism 7-10 to detect whether the cargo basket is in place; The main controller of the control center is a PLC controller. The conveying track 1 comprises two parallel tracks, on which double rows of chains are installed, and the chains are driven by rotating shafts to transport the cargo baskets. The middle position of the conveying track 1 is provided with a barcode scanning gun 2, which scans the barcodes pasted on both sides of the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com