Prediction methods and systems for structural repair during heavy maintenance of aircraft

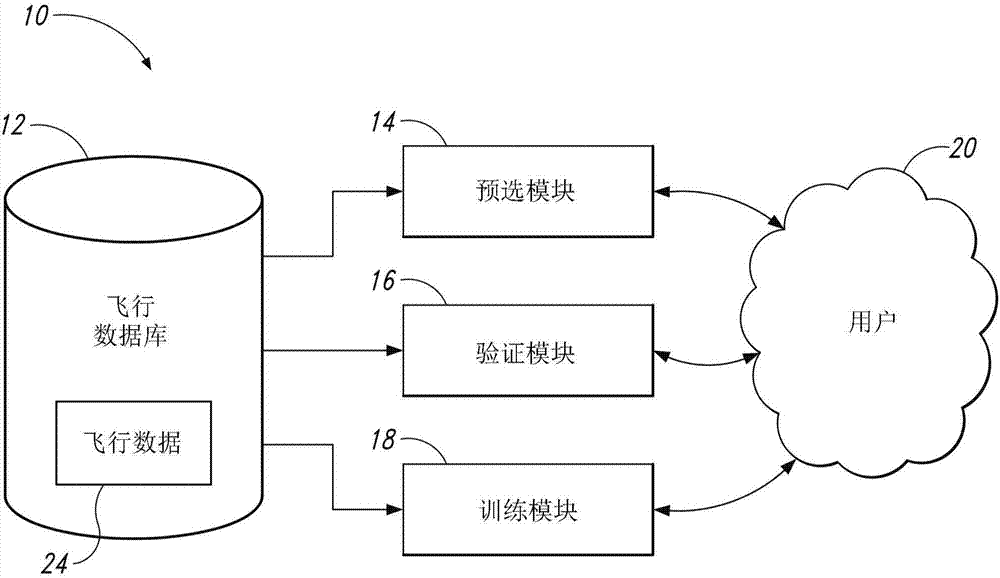

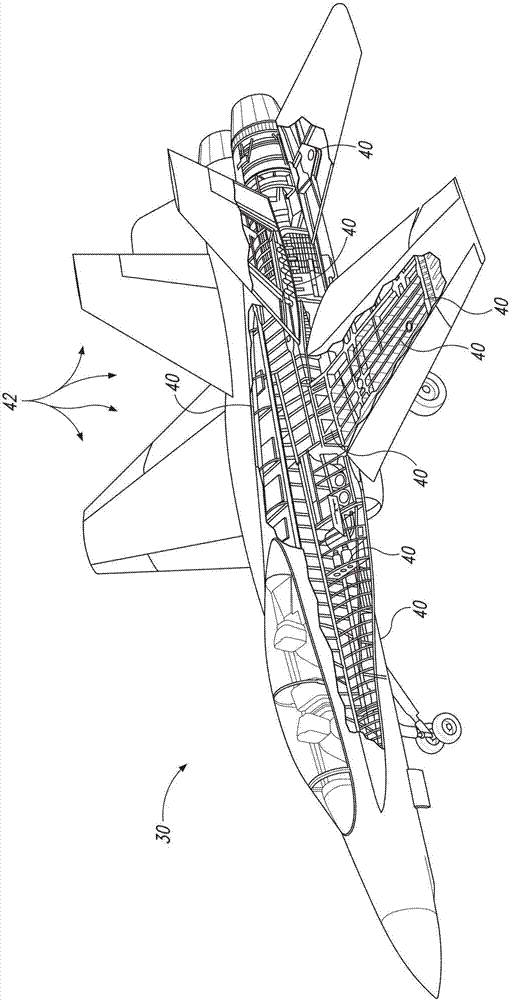

A technology of aircraft and predictive models, applied in general control systems, test/monitoring control systems, control/regulation systems, etc., can solve problems such as unpredictable downtime of aircraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

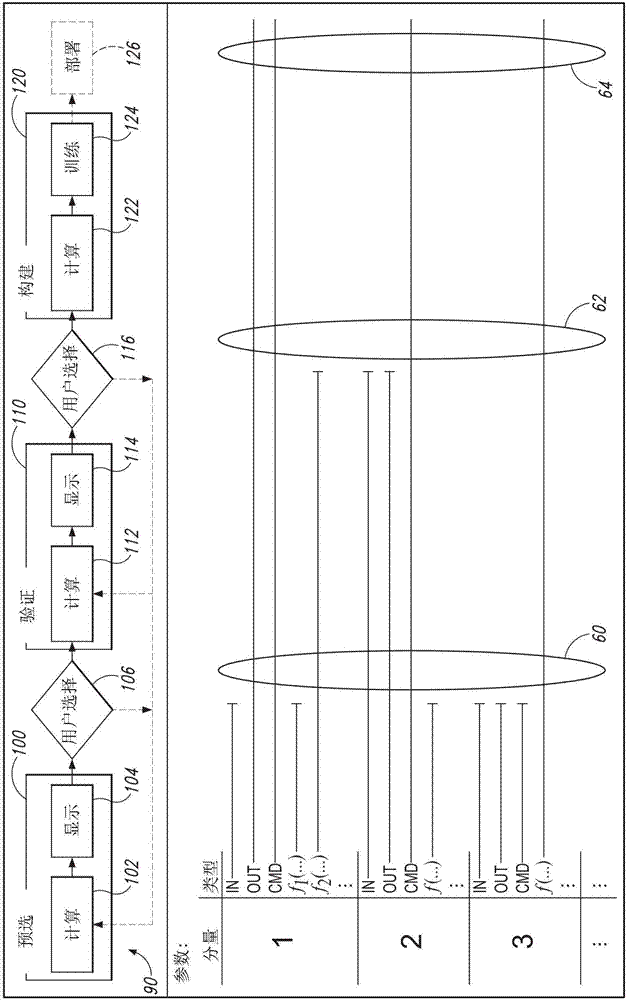

[0158] Clause 1. A method for creating a predictive model for structural repair during an overhaul of a fleet of aircraft each including a structural component, the method comprising the steps of:

[0159]performing the following for a first aircraft of the fleet of aircraft, wherein the first aircraft undergoes replacement of the structural component of the first aircraft during an overhaul of the first aircraft:

[0160] calculating a preselected data set of fatigue-related parameters from data collected during a first set of flights of the first aircraft, wherein each flight of the first set of flights occurs during an overhaul of the first aircraft before, and wherein, during each flight of the first set of flights, the first aircraft experienced an overstress event;

[0161] displaying said preselected data set; and

[0162] receiving a selection of said fatigue-related parameters;

[0163] performing the following for a second aircraft of the fleet of aircraft, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com