A tobspin cutter zero position correction device

A technology of zero correction and cutting machine, which is applied in the fields of tobacco, metal processing, and tobacco processing, and can solve problems such as potential safety hazards of equipment, complicated and cumbersome calibration process, and discrepancy between refined equipment management level and safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

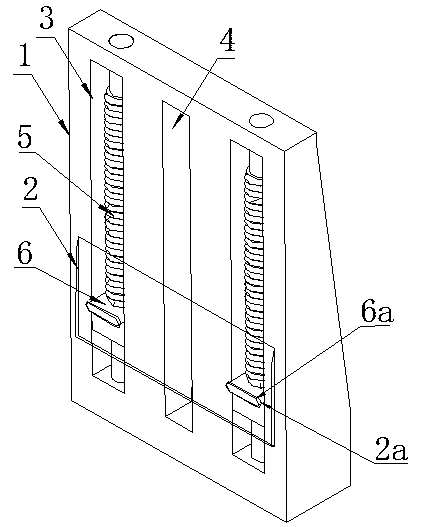

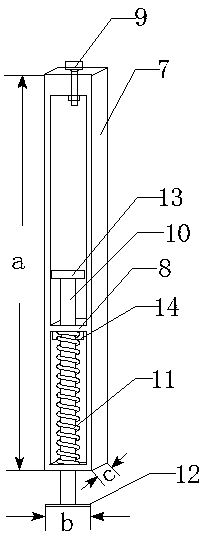

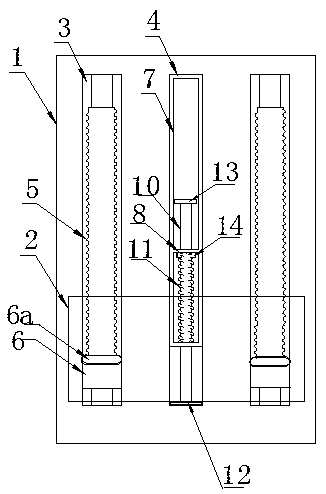

[0016] like figure 1 shown is a front view of the present invention, a in the figure represents the length of the reset bracket 7, b represents the width of the reset bracket 7, c represents the depth of the reset bracket 7, the present invention includes the reset bracket 7, the reset baffle 8 and elastic push knife correction mechanism, the reset bracket 7 is a frame-shaped bracket, the upper frame of the frame-shaped bracket is provided with a mounting through hole, and is matched with a screw assembly 9, and the screw assembly 9 is a frame-shaped bracket. The upper frame of the bracket is fixed with the upper end of the groove 4 in the middle of the knife feed unit of the TOBSPIN shredder. There is a gap between the lower frame of the frame-shaped support and the lower end of the groove 4 in the middle of the cutting unit of the TOBSPIN shredder. The depth c of the frame-shaped support is less than or equal to the depth of the groove 4 in the middle of the knife feeding u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com