Shutter type vacuum furnace inspection window

An observation window and vacuum furnace technology, applied in the field of flicker-free observation window structure and its protection, can solve the problems of observation window flicker, complex mechanism, high cost, etc., to avoid flicker, reduce the number of parts, and reduce the volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

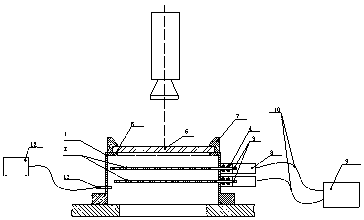

[0018] As shown in the figure, a shutter type vacuum furnace observation window includes an observation window cylinder 1 that can be installed in the observation port of the vacuum furnace, an imaging orifice 2 installed at the front end of the observation window cylinder 1, The rear end is provided with a glass lens 3 and a lens pressing plate 4 , and a sealing ring 5 for forming a vacuum sealing circuit between the lens 3 and the barrel 1 . An argon gas filling channel 6 is arranged between the glass lens 3 and the imaging aperture plate 2 . On the outer side of the glass lens 3 is an imaging lens barrel 7. A focusing lens 8 and an imaging lens 9 are arranged in the lens barrel 7 in turn. There is a circular hole with a diameter of 0.5-2 mm in the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com