Double-taper sleeve type self-lubricating spherical plain bearing pad friction and wear test device

A friction and wear test, joint bearing technology, applied in the direction of measuring devices, wear resistance testing, instruments, etc., can solve the problems of different deformation, can not reflect the actual contact of the bearing liner, etc., to facilitate disassembly, solve the test analysis Convenience, accuracy and reliability of test conditions, and the effect of solving device requirements for accurate measurement and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

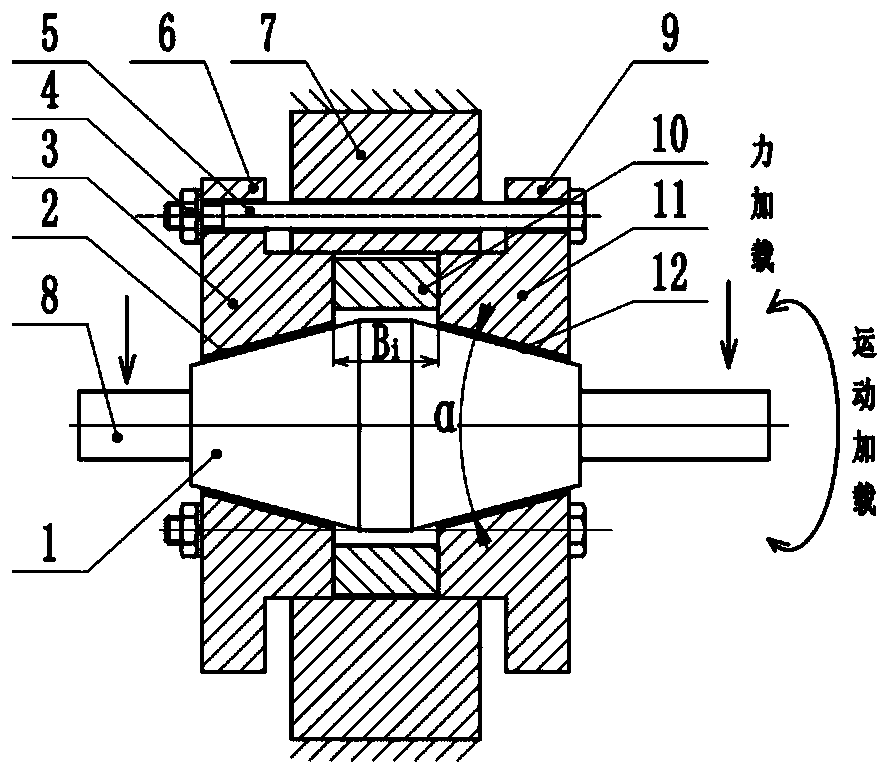

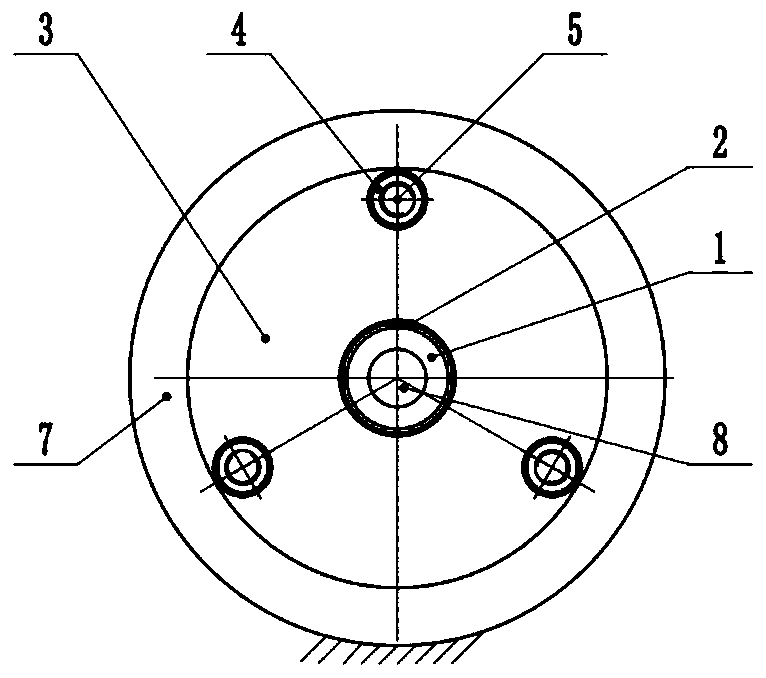

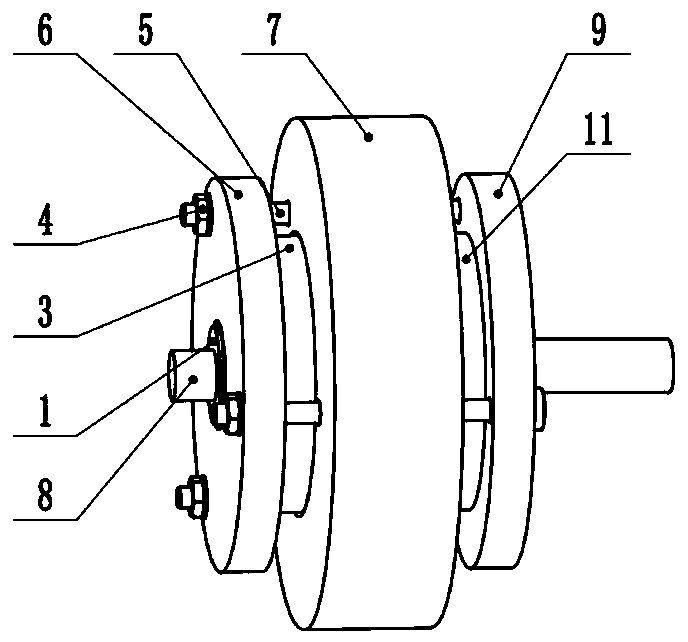

[0016] exist figure 1 , figure 2 and image 3 In the schematic diagram of the friction and wear test device for the double-cone bushing type self-lubricating joint bearing liner shown, the main body of the double-cone shaft 1 is composed of two identical truncated cones with large diameter ends respectively connected to the two ends of the same cylinder , the cone angle of the two truncated cones is α, and α=25°. Short shafts 8 coaxial with the small diameter ends of the two truncated cones are all provided. On the two cones of the double cone shaft, there are corresponding taper sleeves, that is, the left taper sleeve 3 and the right side taper sleeve 11. The central through hole of the cylindrical base of the two taper sleeves is the truncation of the double taper shaft. The conical through hole corresponding to the cone has a cone angle of α. A left flange 6 and a right flange 9 are connected to the small central hole of the cylindrical substrate and have the same end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com