Fire-resistant pipe coupling

A technology of pipe couplings and refractory materials, applied in the direction of pipes/pipe joints/fittings, adjustable connections, pipeline protection, etc., to reduce installation costs, eliminate the need for lubrication, and increase the time saved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

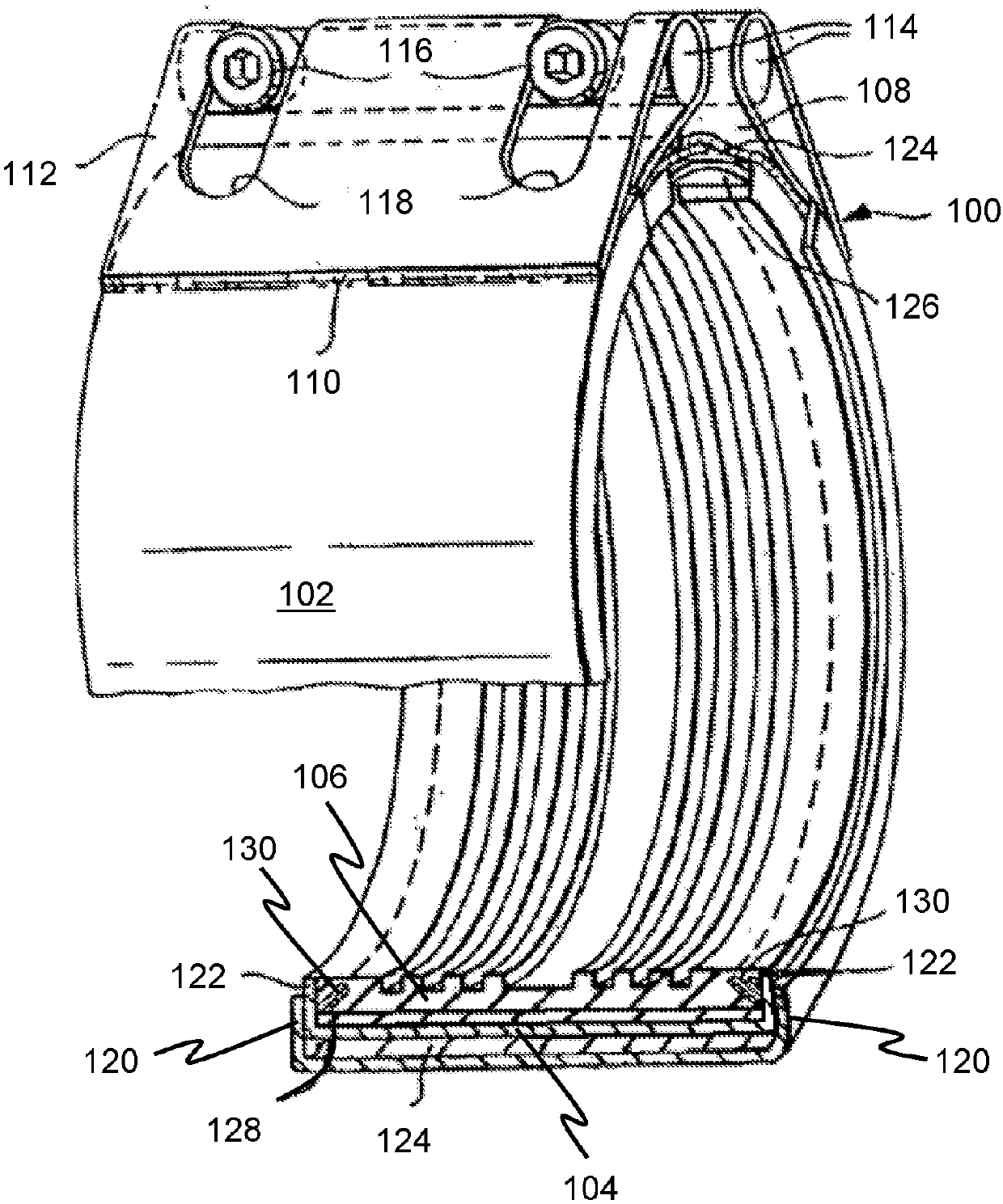

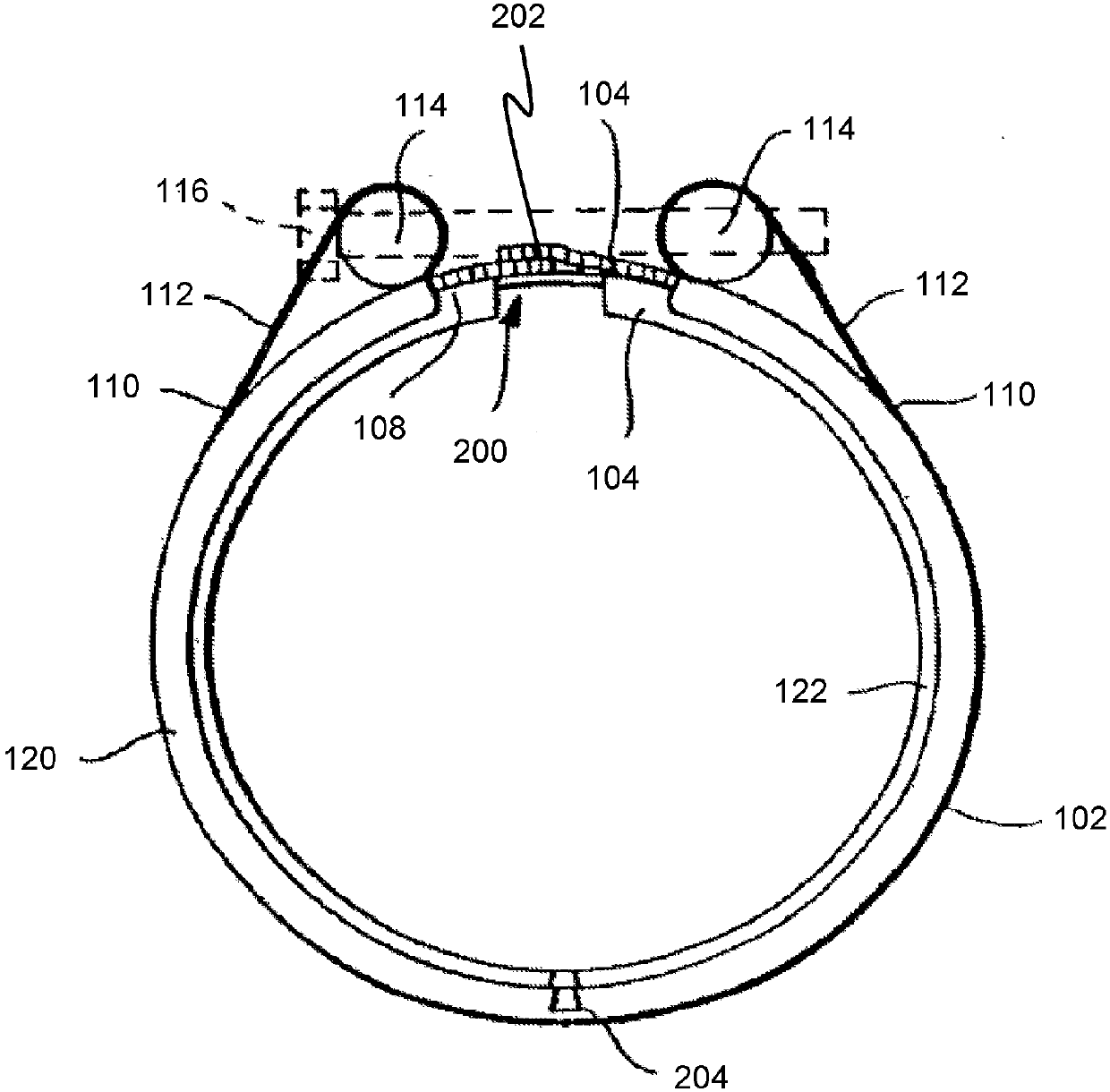

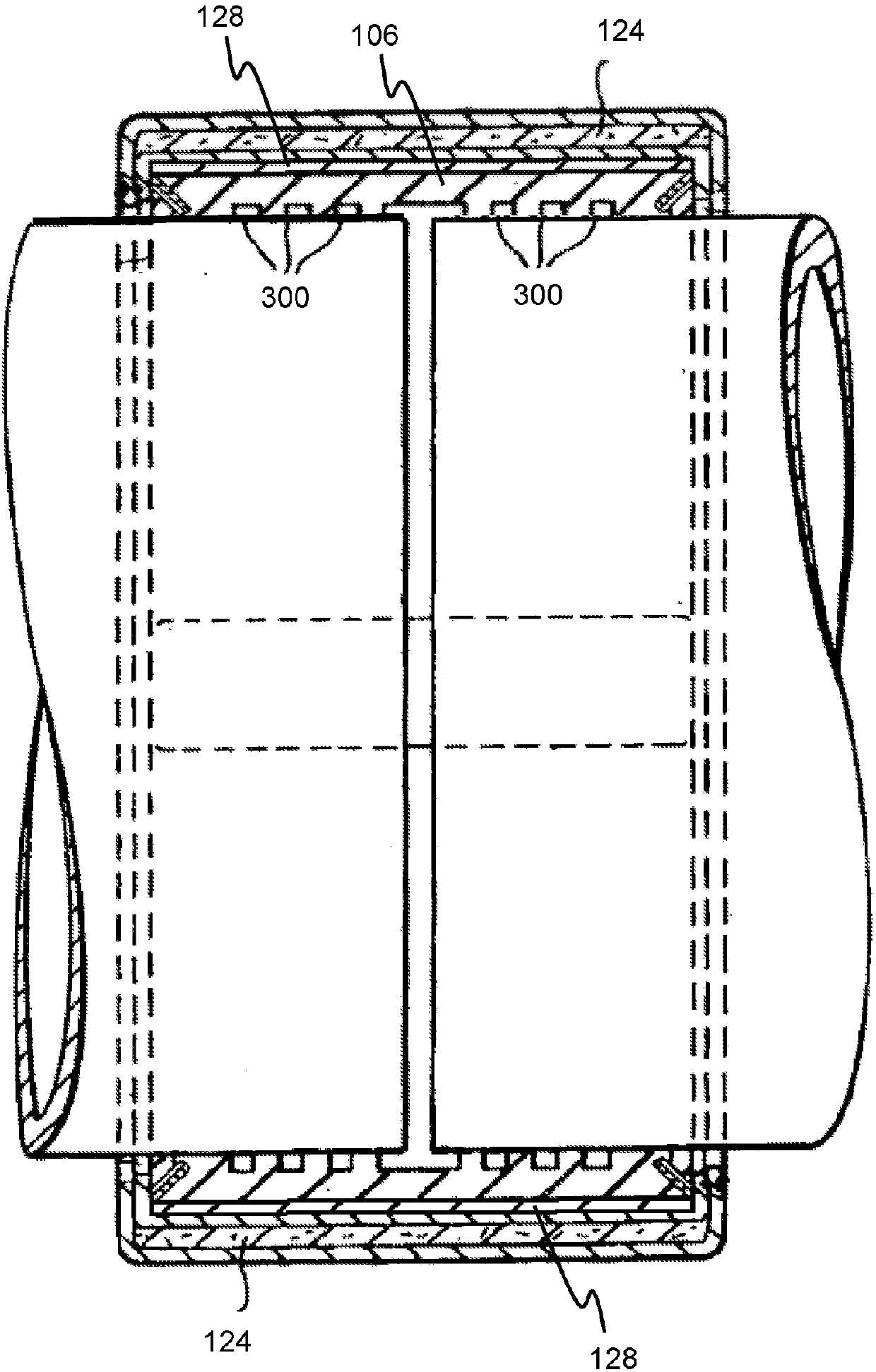

[0059] The pipe coupling 100 includes a tubular outer housing 102 , a tubular inner housing 104 and a tubular sealing gasket 106 . The tubular outer shell 102 is formed from rolled steel and has a longitudinal gap 108 . The shell is folded back onto itself at its free end and welded at 110 to form a ring 112 along the opposite edge of the longitudinal gap 108 . A pin 114 is inserted into the ring. A tension screw 116 passes through a transverse hole in one of the pins 114 into a threaded transverse hole in the other of the pins 114 to interconnect the two free ends of the outer housing 102 .

[0060] Slots 118 are cut into ring 112 to provide room for screws. The axial end edges of the housing 102 are bent inwardly at right angles to form an annular flange 120 .

[0061]The tubular inner casing 104 is formed from rolled steel and has a longitudinal gap. The axial end edges of the inner housing 104 are bent inwardly at right angles to form an annular flange 122 . The inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com